Method for coating granular fertilizer

A granular fertilizer and coating technology, applied in the direction of organic fertilizer, inorganic fertilizer, fertilizer mixture, etc., can solve the problems of different specific gravity and fineness, unstable product quality, and affect the use effect, so as to achieve uniform and stable properties and improve product quality Stability, effect of increasing fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

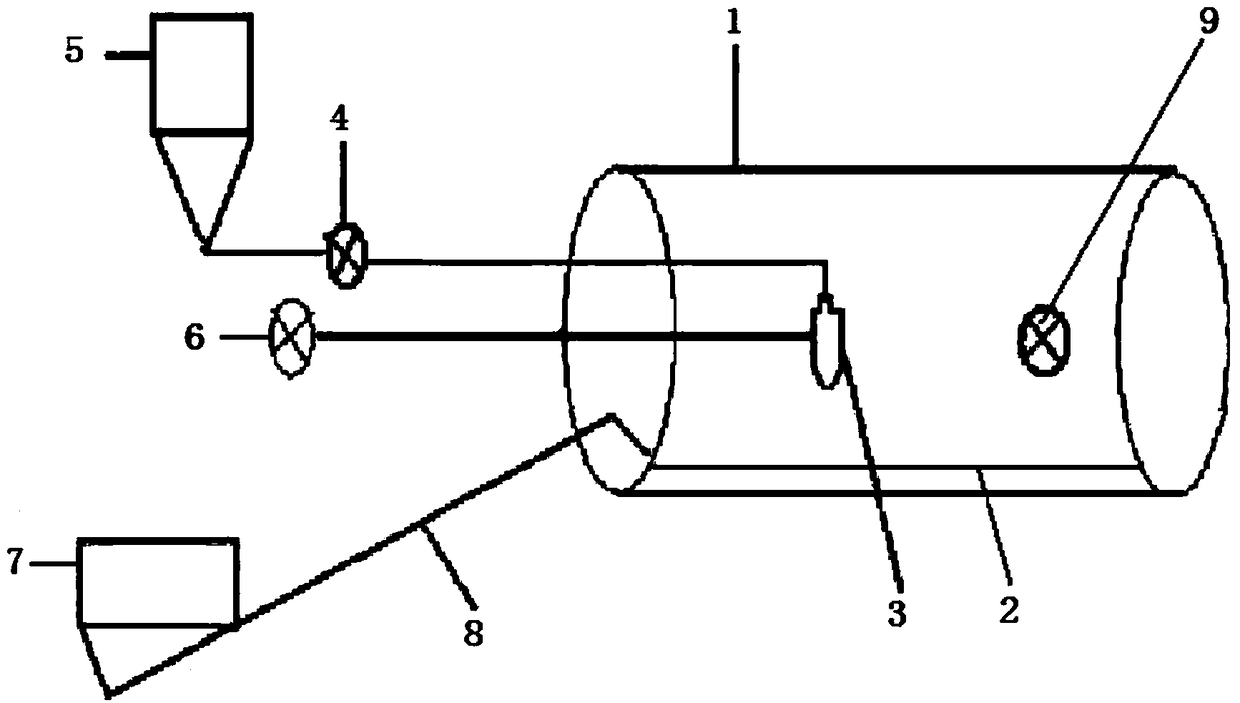

[0045] Such as figure 1 As shown, a spraying device includes: a coating machine 1, an auger 2, a nozzle 3, a screw pump 4, a hopper 5, an air compressor 6, a silo 7, a feeding belt 8 and a powder spreader 9.

[0046] The auger 2 is arranged in the coating machine 1 for transporting granular fertilizers.

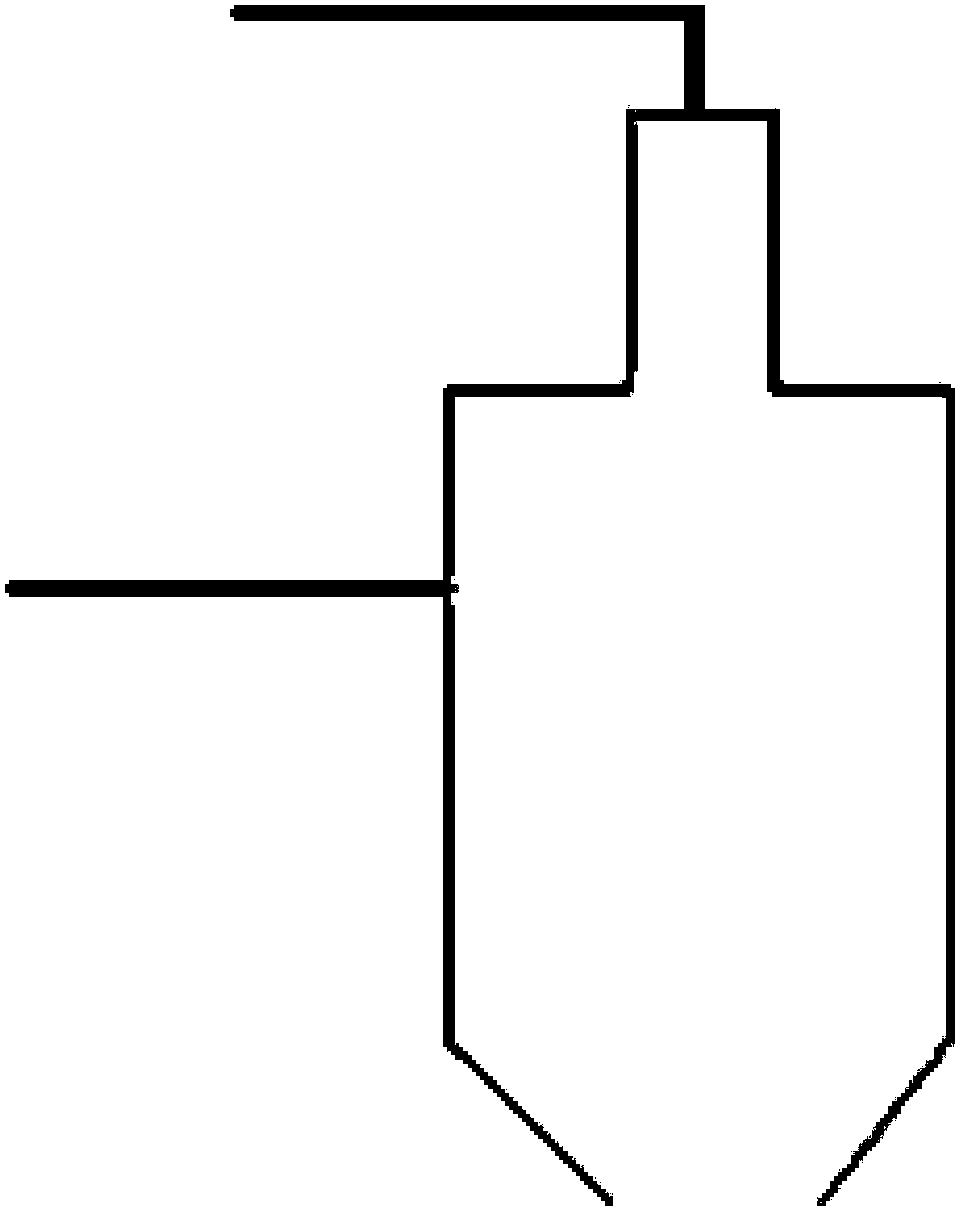

[0047] Nozzle 3 is arranged on the top of auger 2, and is used for spraying the coating agent to the granular fertilizer on the auger 2; as figure 2 As shown, the diameter of the outlet at the lower end of the nozzle 3 is 0.5-1 cm, and the outlet at the lower end is in the shape of a "V".

[0048] The spray head 3 is connected with the screw pump 4, and the screw pump 4 is used to transport the coating agent in the hopper 5 to the spray head 3.

[0049] The spray head 3 is connected with the air compressor 6, and the air compressor 6 is used to provide pressurized gas to the spray head 3 to spray the coating agent in the spray head 3.

[0050] The feeding belt 8 is arranged...

Embodiment 2

[0060] The specific operation steps are as follows:

[0061] (1) Preparation of suspension: at room temperature, weigh 3g of xanthan gum, 30g of potassium chloride, 80g of attapulgite, and 2g of sodium polyacrylate; , to obtain a suspending agent;

[0062] (2) Preparation of coating agent: add 0.5 kg of trace material to 0.8 kg of suspending agent, that is, add 0.5 kg of microbial bacterial powder, and stir evenly to obtain coating agent;

[0063] (3) The granular fertilizer is passed through the spraying device of embodiment 1 (the diameter of the discharge port at the lower end of the spray nozzle 3 is 0.5 cm), and the coating agent and talcum powder are successively wrapped on its surface. The specific steps are: pour the fertilizer granules into the silo 8, and the feeding belt 9 continuously feeds the granule fertilizer in the silo 8 into the coating machine 1 at a constant speed, and the feeding amount is 1.5 tons in 5 minutes. Pour the coating agent into the hopper 5,...

Embodiment 3

[0066] The specific operation steps are as follows:

[0067] (1) Preparation of suspending agent: at room temperature, weigh 8g of xanthan gum, 60g of potassium chloride, 200g of attapulgite, and 10g of sodium polyacrylate, mix well, add in a reaction kettle with 1800g of water, and stir for 2 hours , to obtain a suspending agent;

[0068] (2) Preparation of coating agent: add 1 kg of trace material to 2 kg of suspending agent, namely add 1 kg of microbial bacterial powder, and stir evenly to obtain coating agent;

[0069] (3) The granular fertilizer is passed through the spraying device of embodiment 1 (the diameter of the discharge port at the lower end of the spray nozzle 3 is 1 cm), and the coating agent and talcum powder are wrapped successively on its surface. The specific steps are: pour the fertilizer granules into the silo 8, and the feeding belt 9 continuously feeds the granule fertilizer in the silo 8 into the coating machine 1 at a constant speed, and the feeding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com