Zirconium-containing alumina hollow sphere insulating brick and preparation method thereof

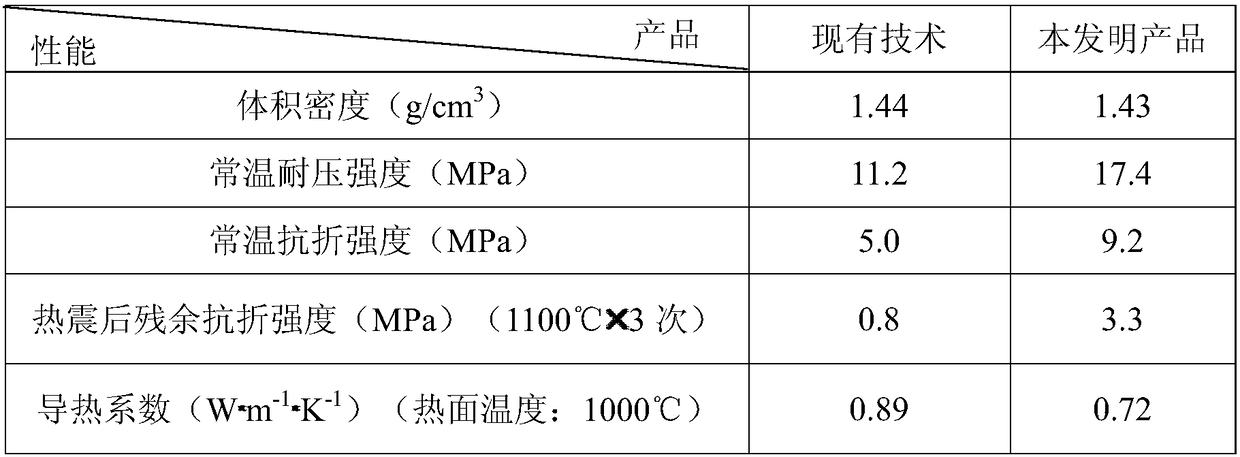

An alumina hollow sphere, zirconium alumina technology, applied in the field of refractory materials, can solve the problems of low strength, poor thermal shock stability, short service life, etc., and achieve the effect of improving thermal shock stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A zirconium-containing alumina hollow sphere heat-insulating brick, whose components include 69% of alumina hollow spheres with a particle size of 0-3mm and an aluminum content ≥ 99.5%, 21% of alumina micropowder of 3-5um, and 325-mesh zircon Fine powder 10%.

[0030] The sum of the weight percentages of the above components is 100%, and the following weight percentages are additionally added, and the calculation basis of the added amount is the weight sum of the above components: aluminum sulfate and aluminum dihydrogen phosphate composite binder 8.5%.

[0031] The preparation method of the zirconium-containing alumina hollow spherical heat insulation brick is as follows:

[0032] (1) Weigh alumina micropowder and zirconite powder respectively according to the above requirements, mix the weighed alumina micropowder and zirconite powder for 15-20 minutes, and then place the weighed components in a vibrating mill for mixing uniform and ready for use;

[0033] (2) After...

Embodiment 2

[0036] A zirconium-containing alumina hollow sphere heat insulation brick, the components of which include 35% alumina hollow spheres with a particle size of 0-3 mm and an aluminum content ≥ 99.5%, and alumina hollow spheres with a particle size of 0-3 mm and a zirconium content of 5% 25%, 35% of 3-5um alumina powder, 3-5um monoclinic zirconia or oxide-stabilized zirconia (yttrium oxide or magnesium oxide stabilized) 5%.

[0037] The sum of the weight percentages of the above components is 100%, and the following weight percentages are additionally added, and the calculation basis of the added amount is the weight sum of the above components: 12% of dextrin.

[0038] The preparation method of the zirconium-containing alumina hollow spherical heat-insulating brick is the same as that in Example 1, except that the semi-finished product is dried at 130°C for 48 hours, fired at 1680°C, and kept for 9 hours.

Embodiment 3

[0040] A zirconium-containing alumina hollow sphere heat-insulating brick, the components of which include 50% of alumina hollow spheres with a particle size of 0-3mm, 36% of alumina micropowder of 3-5um, and 14% of 325-mesh zircon mullite fine powder.

[0041] The sum of the weight percentages of the above components is 100%, and the following weight percentages are additionally added, and the calculation basis of the added amount is the weight sum of the above components: phosphoric acid 10%.

[0042] The preparation method of the zirconium-containing alumina hollow sphere heat-insulating brick is the same as that in Example 2, except that the semi-finished product is dried at 110°C for 12 hours, fired at 1580°C and held for 8 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com