Preparation method of feed grade calcium phosphate salt

A calcium phosphate, feed-grade technology, applied in the field of phosphorus chemical industry, can solve the problems of high purification cost of production process and low removal efficiency of heavy metals, and achieve the effect of reducing adverse effects and improving product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

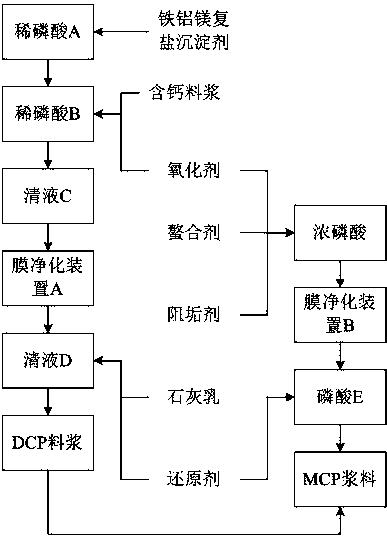

Image

Examples

Embodiment 1

[0035] Step a: with P 2 o 5 Dilute phosphoric acid A with a concentration of 15% is used as a raw material, and HF and 40% of the total mass of iron, aluminum and magnesium are added with HF and 40% of NaF to remove the iron, aluminum and magnesium cations in the dilute phosphoric acid to obtain clarified dilute phosphoric acid B for subsequent use;

[0036] Step b: The clarified dilute phosphoric acid B is neutralized with the mixed slurry containing 30% calcium carbonate and calcium bicarbonate to adjust the pH of the dilute phosphoric acid to 3.0, and at the same time add ammonium persulfate in an amount of 5 times the theoretical amount. The reaction time is 2 hours, the reaction temperature is 60°C, the neutralized slag is separated by sedimentation, and the supernatant C is set aside;

[0037]Step c: Serum C is mixed with 0.001% BPBP antiscalant and enters membrane purification device A. A group of protein membranes is assembled in membrane purification device A. The ad...

Embodiment 2

[0042] Step a: with P 2 o 5 Dilute phosphoric acid A with a concentration of 20% is used as a raw material, and HF with 80% iron, aluminum and magnesium mass and 30% KF are added to remove iron, aluminum and magnesium cations in the dilute phosphoric acid to obtain clarified dilute phosphoric acid B for later use;

[0043] Step b: Neutralize the clarified dilute phosphoric acid B with the mixed slurry containing 50% calcium hydrogen phosphate, adjust the pH of dilute phosphoric acid to 2.7, and add perchloric acid at the same time, the addition amount is 20 times the theoretical amount, and the reaction time is 1.5h , the reaction temperature is 60°C, the neutralized slag is separated by sedimentation, and the supernatant C is set aside;

[0044] Step c: The supernatant C is mixed with 0.005% PBTCA antiscalant and enters the membrane purification device A. The membrane purification device A is equipped with 2 sets of protein membranes, and the adsorption capacity of a single ...

Embodiment 3

[0049] Step a: with P 2 o 5 Dilute phosphoric acid A with a concentration of 20% is used as raw material, and 100% NaF and 100% NH of iron, aluminum and magnesium are added. 4 F, removing iron, aluminum and magnesium cations in dilute phosphoric acid to obtain clarified dilute phosphoric acid B for subsequent use;

[0050] Step b: Neutralize the clarified dilute phosphoric acid B with 90% calcium hydroxide containing water, adjust the pH of the dilute phosphoric acid to 2.3, and add potassium permanganate at the same time, the amount added is 50 times the theoretical amount, the reaction time is 2.5h, The temperature is 70°C, the neutralized slag is separated by sedimentation, and the supernatant C is used for later use;

[0051] Step c: Serum C is mixed with 0.0071% HEDP antiscalant and enters membrane purification device A. Membrane purification device A is equipped with 3 groups of protein membranes. The adsorption capacity of a single group of protein membranes reaches 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com