Numerical control lathe tailstock control method using V-shaped block for centering

A CNC lathe tailstock and CNC lathe technology, applied in the direction of tailstock/top, turning equipment, manufacturing tools, etc., can solve the problems of low axial dimension control precision, tailstock cannot be automatically fed, and low processing efficiency, etc., to achieve The effect of improving flexibility, precise dimensional accuracy, and increasing the degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

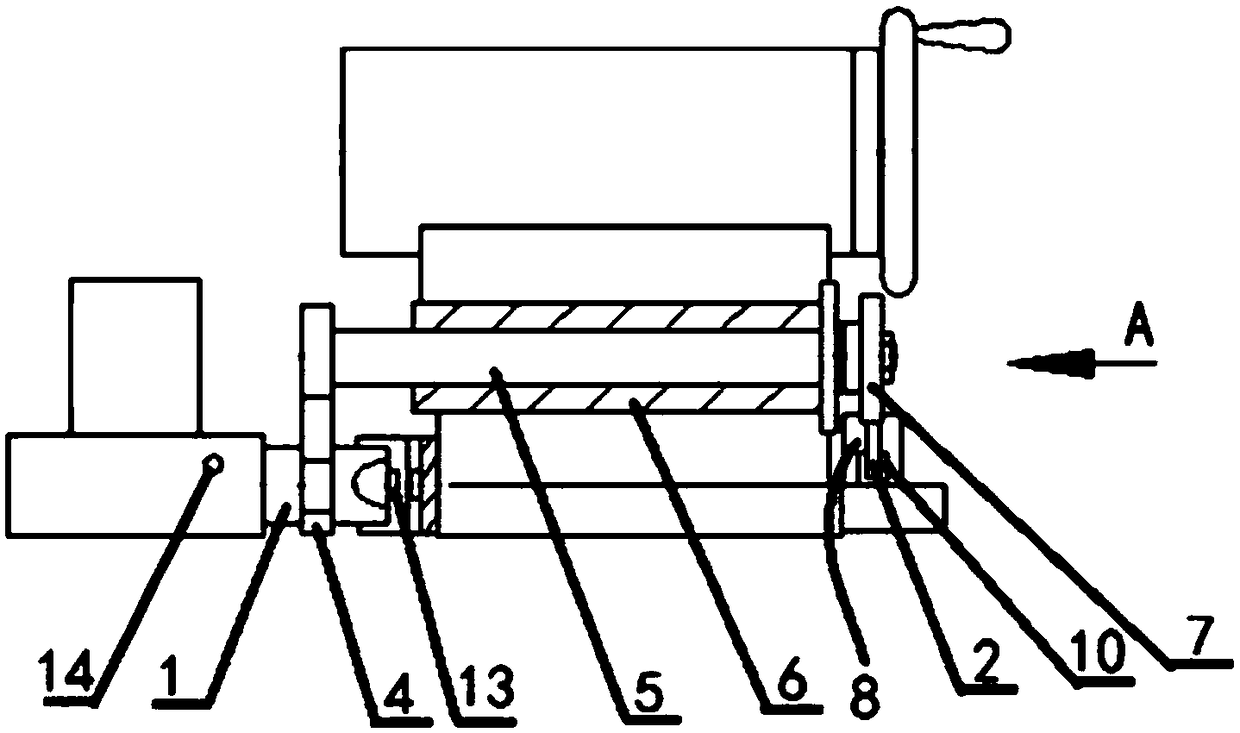

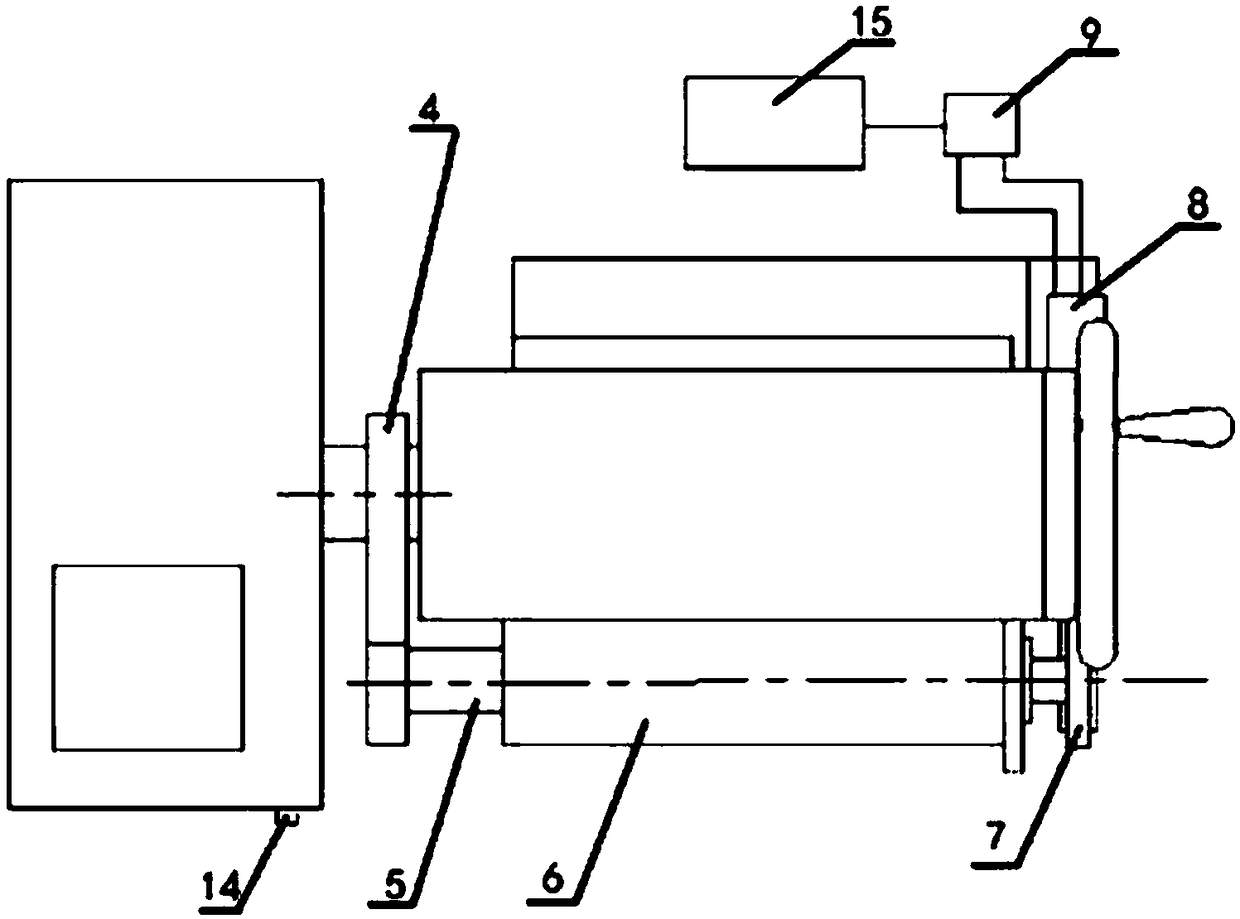

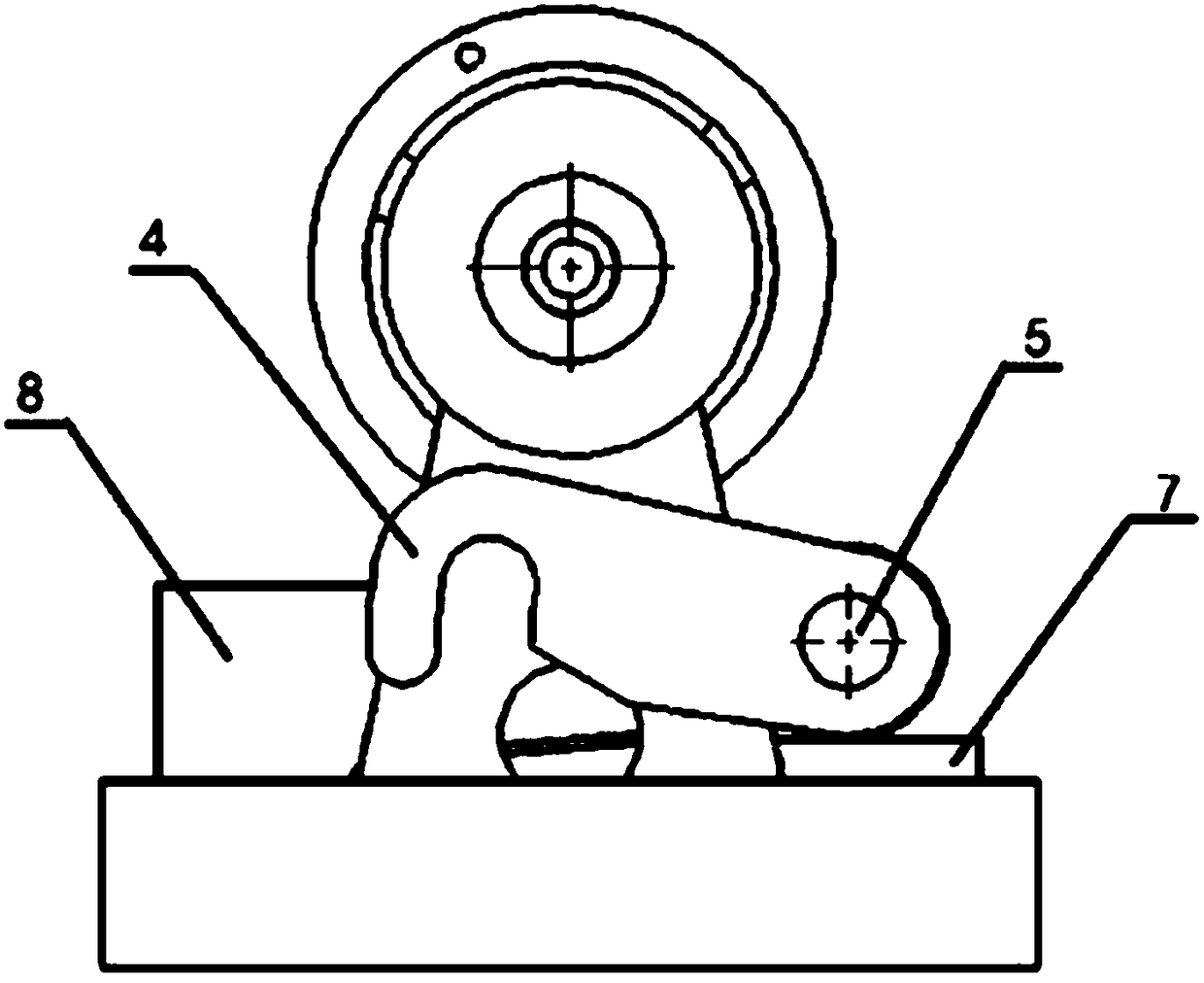

[0017] A method for controlling the tailstock of a CNC lathe centered with a V-shaped block, which uses a cylinder to realize the coupling and disengagement of the saddle and tailstock of the CNC lathe, including a centering component, a rotating arm component and a driving component , the centering assembly includes a centering shaft 1 and a V-shaped block 16, the shaft end of the centering shaft 1 near the tailstock is arranged in a V shape, the centering shaft is fixedly connected to the saddle of the CNC lathe, and the V-shaped block 16 is installed horizontally And it is fixedly connected with the tailstock of the CNC lathe, the V-shaped part at the front end of the centering shaft 1 is snapped into the V-shaped block 16 to realize the centering in the front and rear directions of the lathe, and the end surface of the centering shaft 1 close to the tailstock side and the bottom of the V-shaped block 16 A pair of sensors 13 are provided, and the sensors 13 may be magnetic e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com