Protective device of displacement sensor and belt self-moving machine tail with displacement sensor

A technology of displacement sensor and protective device, applied in the direction of conveyor control device, conveyor, conveyor objects, etc., can solve the problems of high cost, difficult maintenance and replacement, high precision requirements, and achieve the effect of avoiding influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to more clearly illustrate the technical solutions of the embodiments of the present invention, the following will briefly introduce the accompanying drawings that need to be used in the embodiments. Obviously, the accompanying drawings in the following description are some embodiments of the present invention. Ordinary technicians can also obtain other drawings based on these drawings on the premise of not paying creative work.

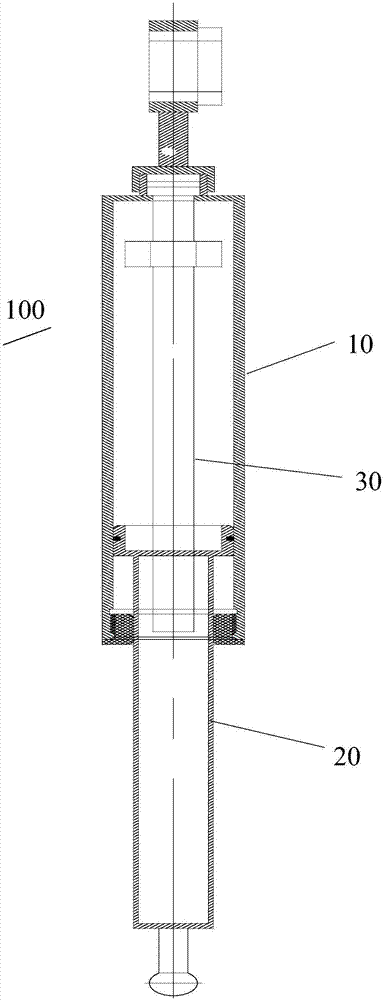

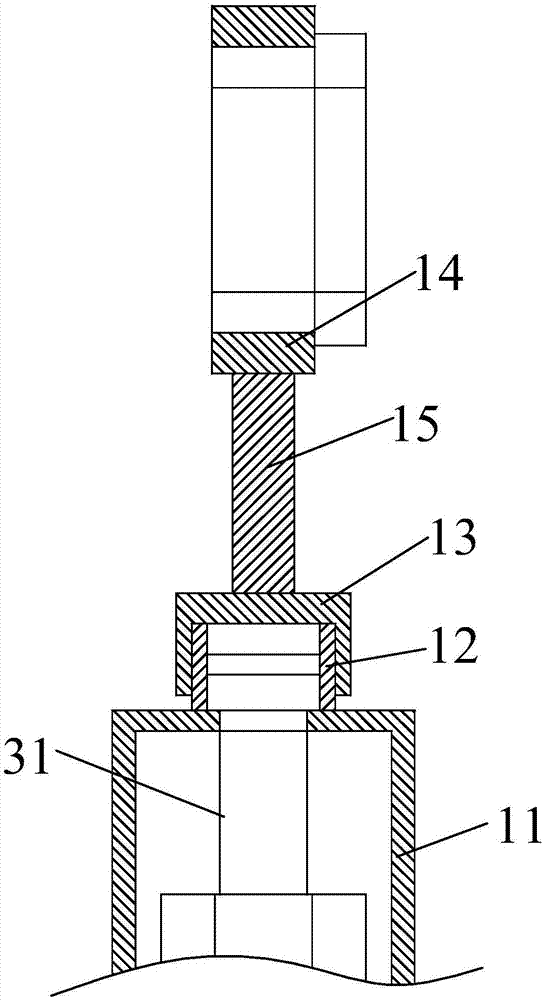

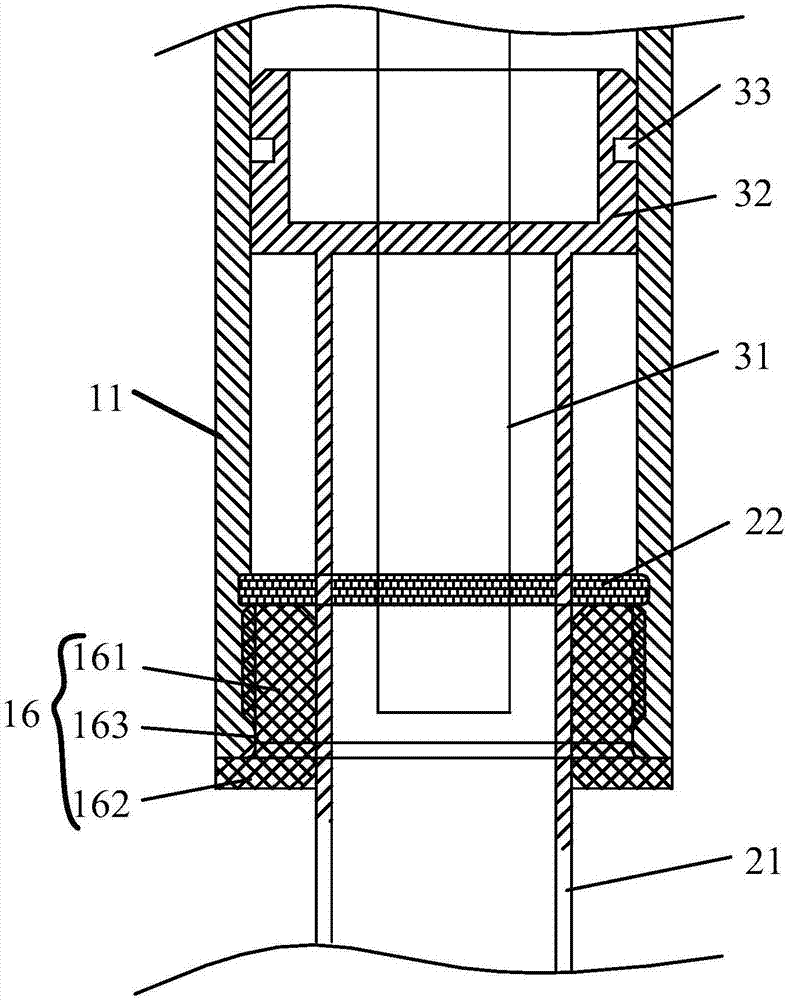

[0024] see Figure 1 to Figure 4 , the embodiment of the present invention provides a displacement sensor protection device 100, including a fixed assembly 10, a sliding assembly 20, a displacement sensor 30, the fixed assembly 10 has a closed cavity for placing the displacement sensor 30, and the sliding assembly 20 is sealed in the fixed assembly 10 The bottom opening of the closed cavity of the fixed assembly 10, and the displacement sensor 30 in the fixed assembly 10 is connected with the sliding assembly 20, so that the displacem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com