Jet laser composite cleaning method and cleaning system

A cleaning system and jet technology, applied in the field of jet laser composite cleaning method and cleaning system, can solve the problems of limited cleaning force, secondary pollution, inconvenient cleaning and clamping of workpieces, etc. The effect of prolonging the effective time of action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

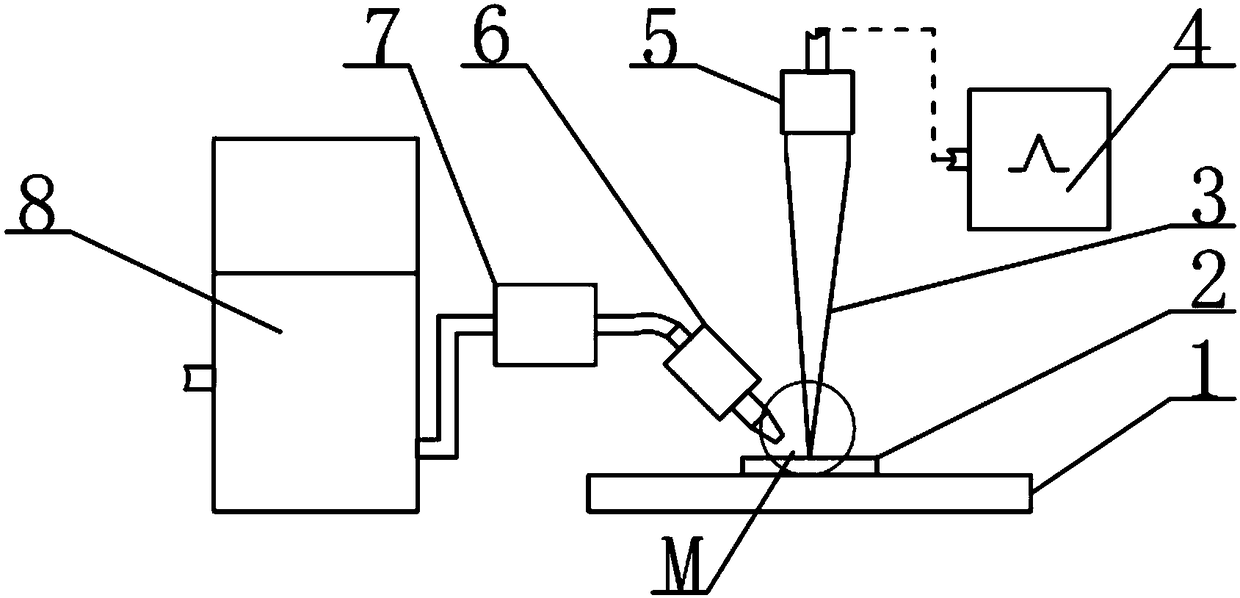

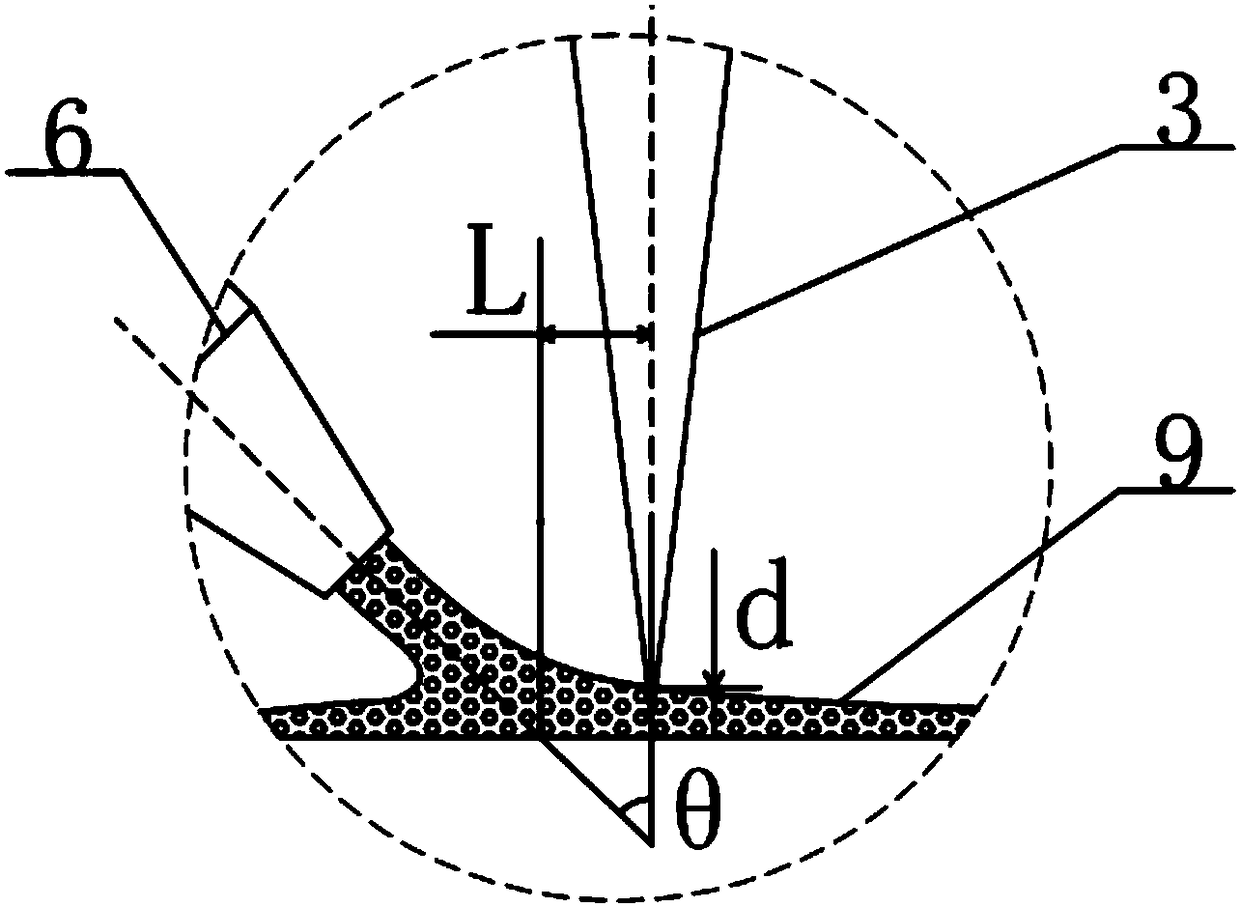

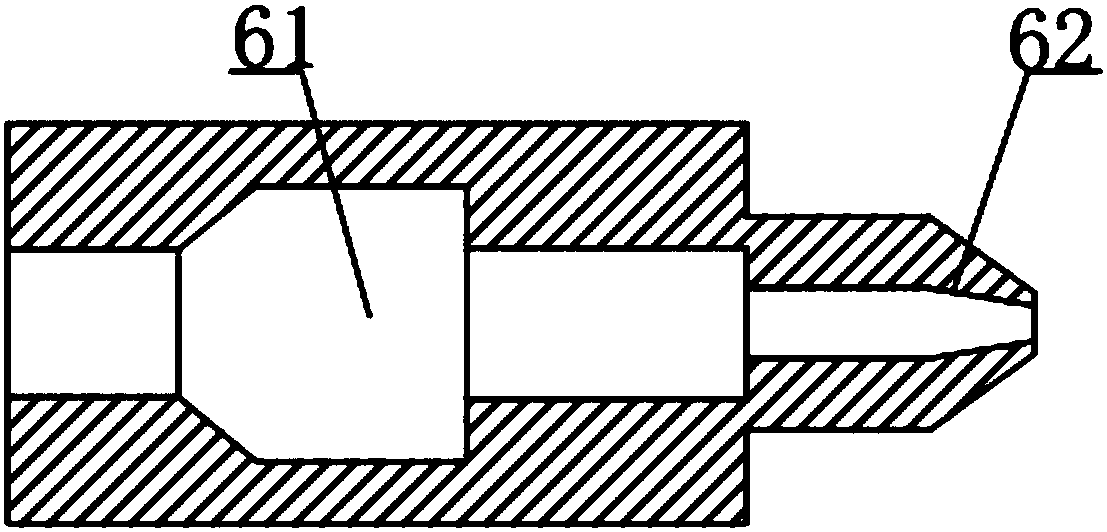

[0026] The structure of the embodiment of the jet laser composite cleaning system is as follows: figure 1 As shown, it includes a water tank 8 , a jet pressurization chamber 7 , a cavitation jet nozzle 6 , a laser 4 and a workbench 1 .

[0027] The workbench 1 in this example is a three-dimensional adjustable workbench with a horizontal surface, and the workpiece 2 in this example is a wafer, which is fixed on the workbench 1 . The outlet pipe of the water tank 8 is connected with the jet pressurization chamber 7, and the outlet of the jet pressurization chamber 7 is connected with the cavitation jet nozzle 6. The water in the water tank 8 is pressurized through the jet pressurization chamber 7, and the high-pressure water flow exits the cavitation jet from the cavitation jet nozzle 6. The laser beam generated by the laser 4 is connected to the fiber laser shaper 5 , and the focal point of the shaped laser beam 3 is in the water film 9 above the workpiece 2 .

[0028] Such a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com