Fountain system

A fountain and filter chamber technology, applied in the direction of spray device, liquid spray device, etc., can solve the problems of single fountain spray effect, unable to complete the neat and consistent adjustment of the nozzle angle, unable to meet the requirements of multi-angle spray, etc., to achieve a wide range of power. , The effect of stable transmission ratio and reduced maintenance rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

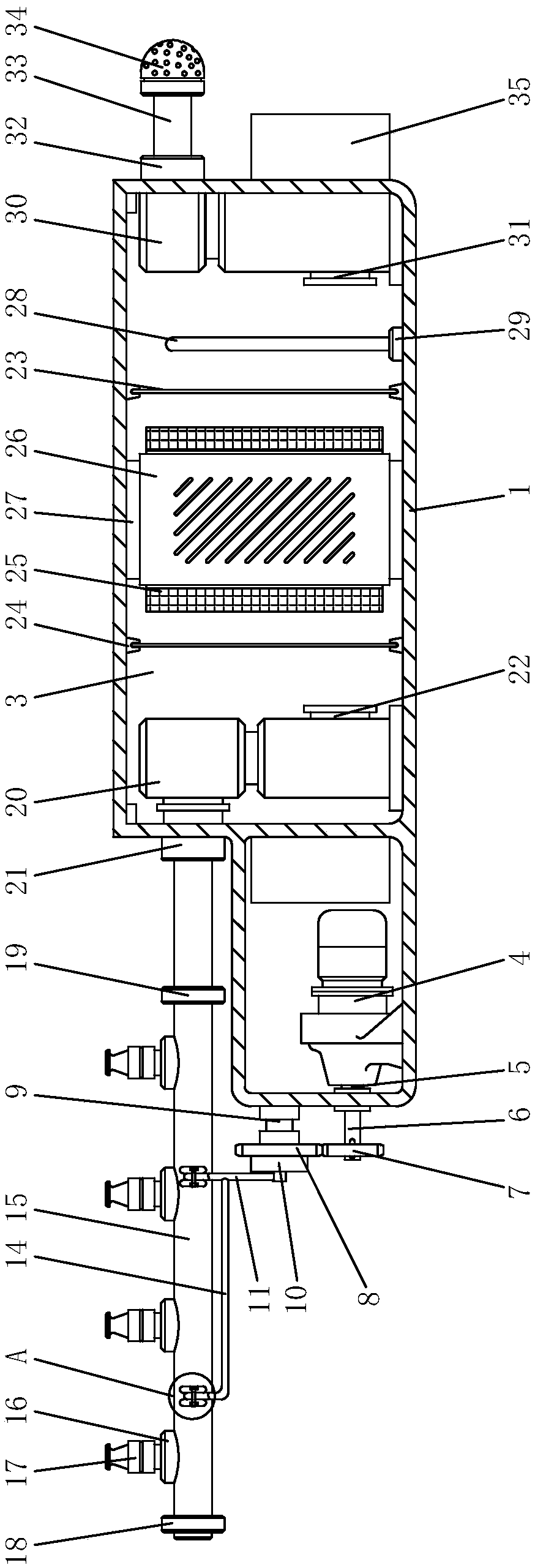

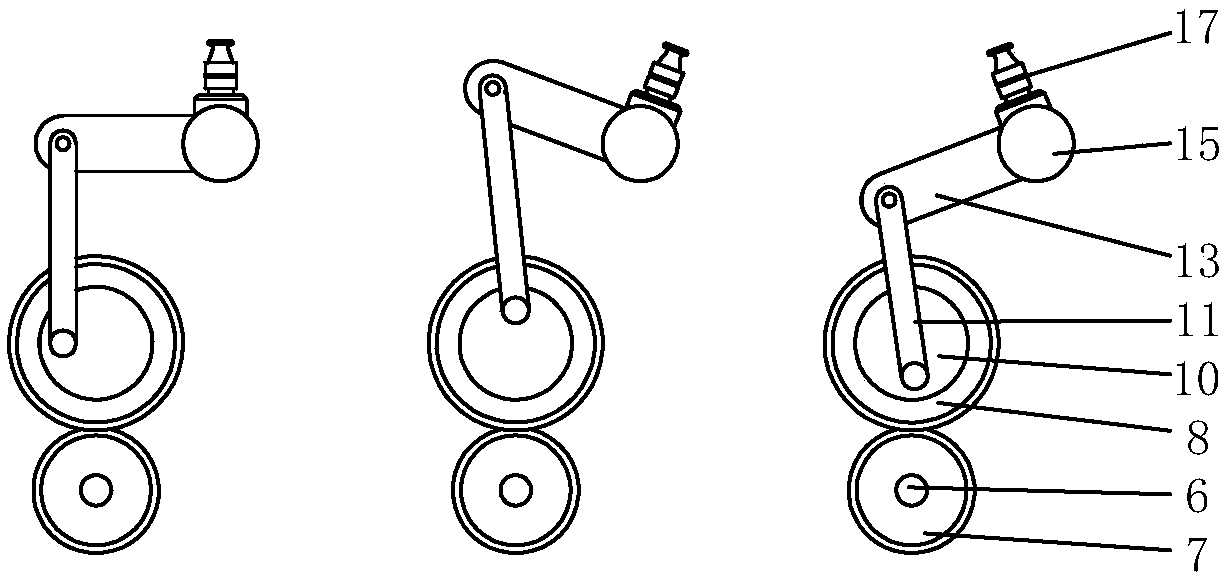

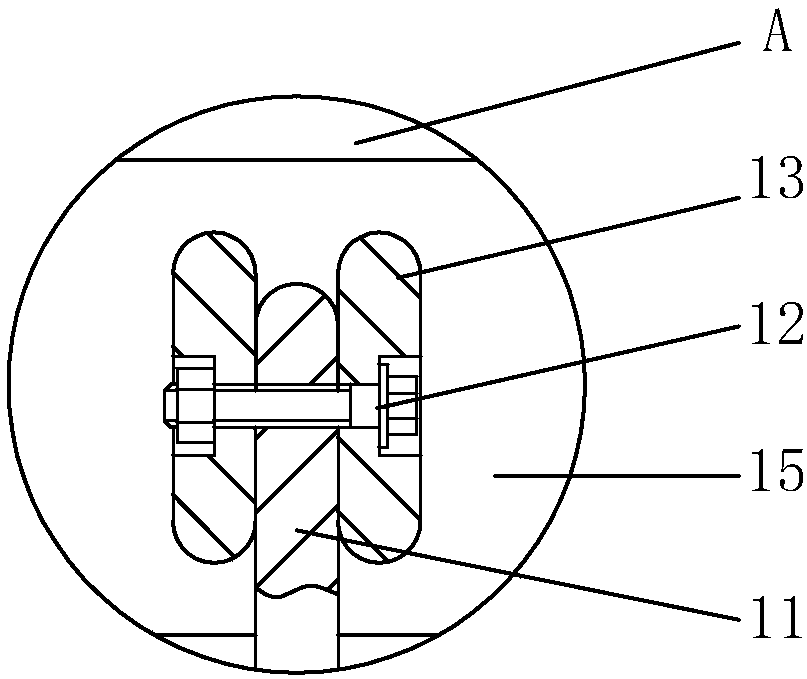

[0046] see Figure 1-3 , the present invention provides a technical solution: a fountain system, including a main body shell 1, an eccentric wheel 10, a branch pipe 16, a pressurizing pump 20, a water level plate 28 and a conversion joint 32, and the inside of the main body shell 1 is respectively provided with a power chamber 2 And the filter chamber 3, and the power chamber 2 is located on the left side of the filter chamber 3, the inside of the power chamber 2 is provided with a motor 4, and the left side of the motor 4 is provided with a sealed bearing 5, and the left side of the sealed bearing 5 is connected to a shaft 6 , and the left end of the shaft 6 is fixed with a driving gear 7, the top of the driving gear 7 is connected with a transmission gear 8, and the right side of the transmission gear 8 is provided with a fixed rotating shaft 9, the shaft 6 runs through the inside of the sealed bearing 5, and the shaft The right end of the rod 6 is integrated with the motor ...

Embodiment 2

[0049] see Figure 4-9, the difference between this embodiment and embodiment 1 is that: the water pump is a diaphragm pump or a plunger pump, and an internal water outlet is provided on the left side of the lower end of the water pump, a water inlet is installed on the right side of the conversion joint, and the conversion joint Located on the upper right side of the main body shell, a filter pump is connected to the right side of the water inlet; the filter pump is not only used to filter impurities, but also cooperates with the water pump to increase the pumping power.

[0050] The filter pump includes a motor 91 , a pump casing 92 and a water wheel 96 rotatably installed in the pump casing and driven by the motor.

[0051] A pump cover 911 is connected to the lower end of the motor, and the pump cover is sealingly connected to the upper end of the pump casing with an open upper end, and a pump chamber is formed between the pump casing and the pump cover.

[0052] The midd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com