Large-span multifunctional plastic greenhouse

A plastic greenhouse, multi-functional technology, applied in greenhouse cultivation, climate change adaptation, horticulture, etc., can solve the problems of poor utilization effect and short utilization time of the greenhouse, and achieves the improvement of the degree of automation, the improvement of the usable time and the utilization effect, and the prevention of water pocket effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

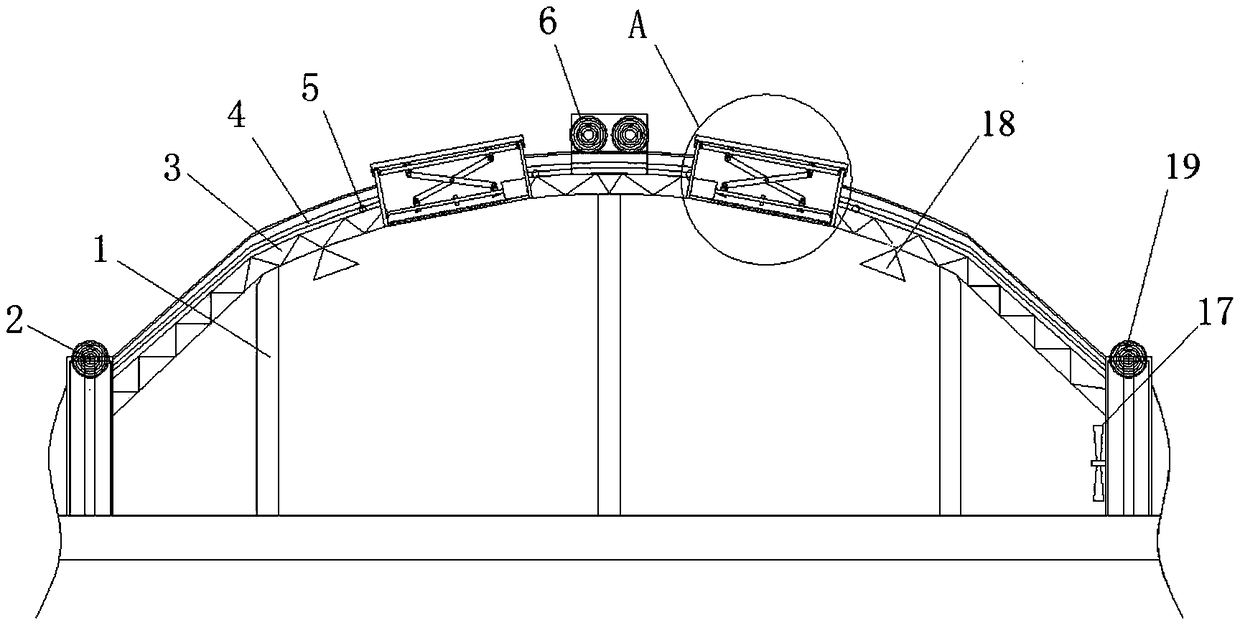

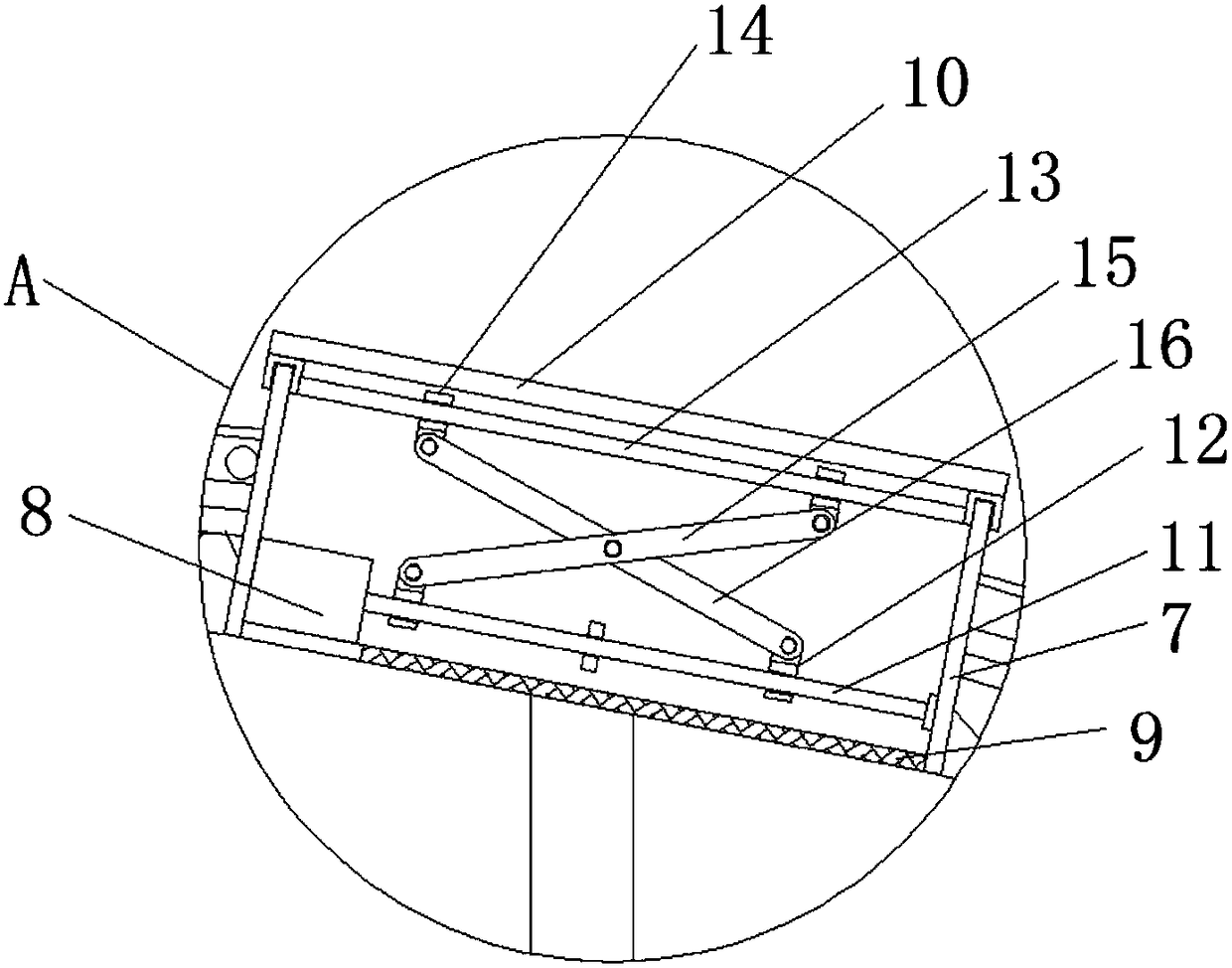

[0022] refer to Figure 1-2 , a large-span multi-functional plastic greenhouse, comprising a column 1, a truss 3 is fixedly installed on the top of the column 1, a steel wire 5 is horizontally drawn on the upper surface of the truss 3, a greenhouse film 4 is fixedly laid on the top of the steel wire 5, and the truss The middle of the top of 3 is symmetrically provided with thermal insulation quilt 6, the top two sides of truss 3 are fixed with rectangular vent 7, the inner wall of one side of rectangular vent 7 is fixed with geared motor 8, and the bottom of rectangular vent 7 runs through truss 3 An insect-proof net 9 is fixedly installed between the bottom inner wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com