Small dimension FPC bending mechanism and bending method thereof

A bending mechanism, small size technology, applied in mechanical/acoustic circuit processing, electrical components, printed circuit manufacturing, etc., can solve the problems of high production cost, low output, waste of manpower, material resources, etc. The effect of production efficiency, reduction of production cost and reduction of human resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

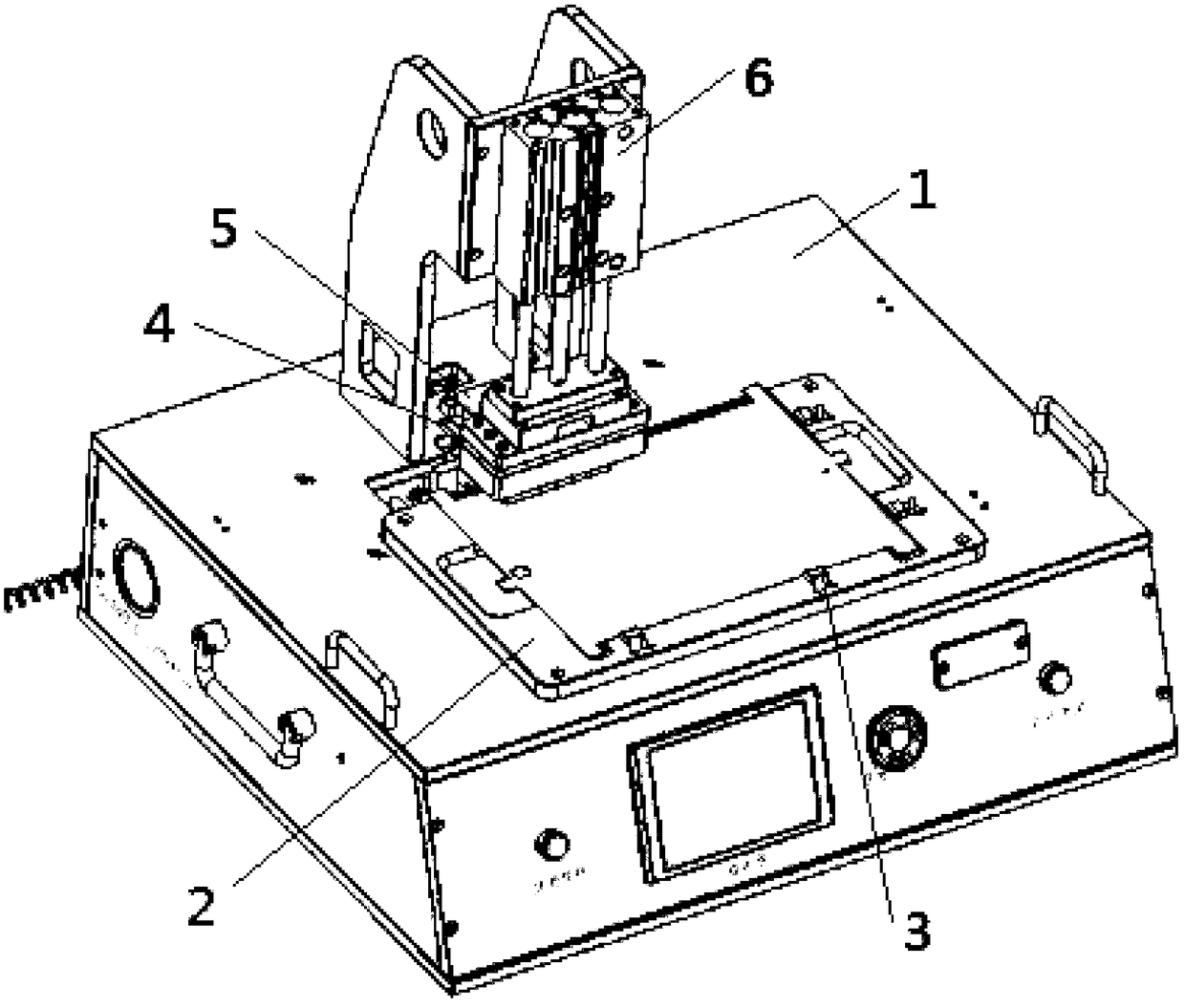

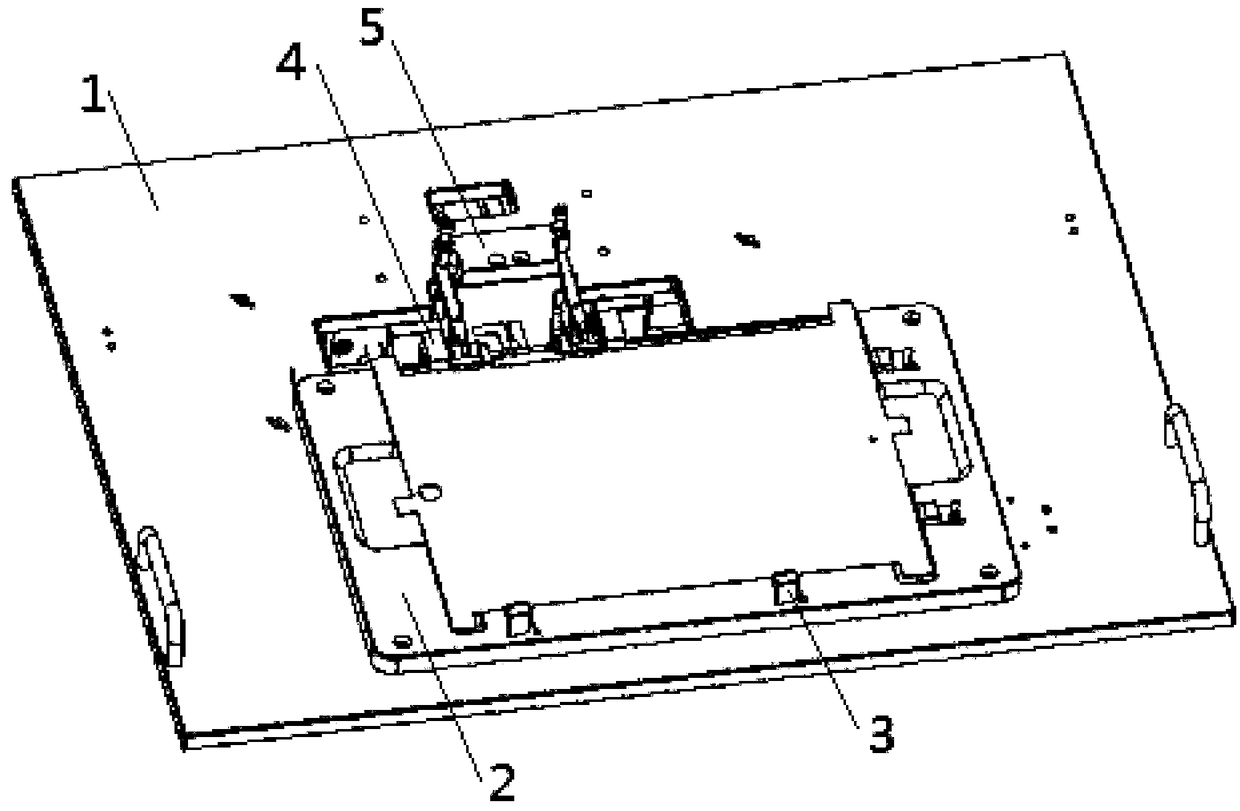

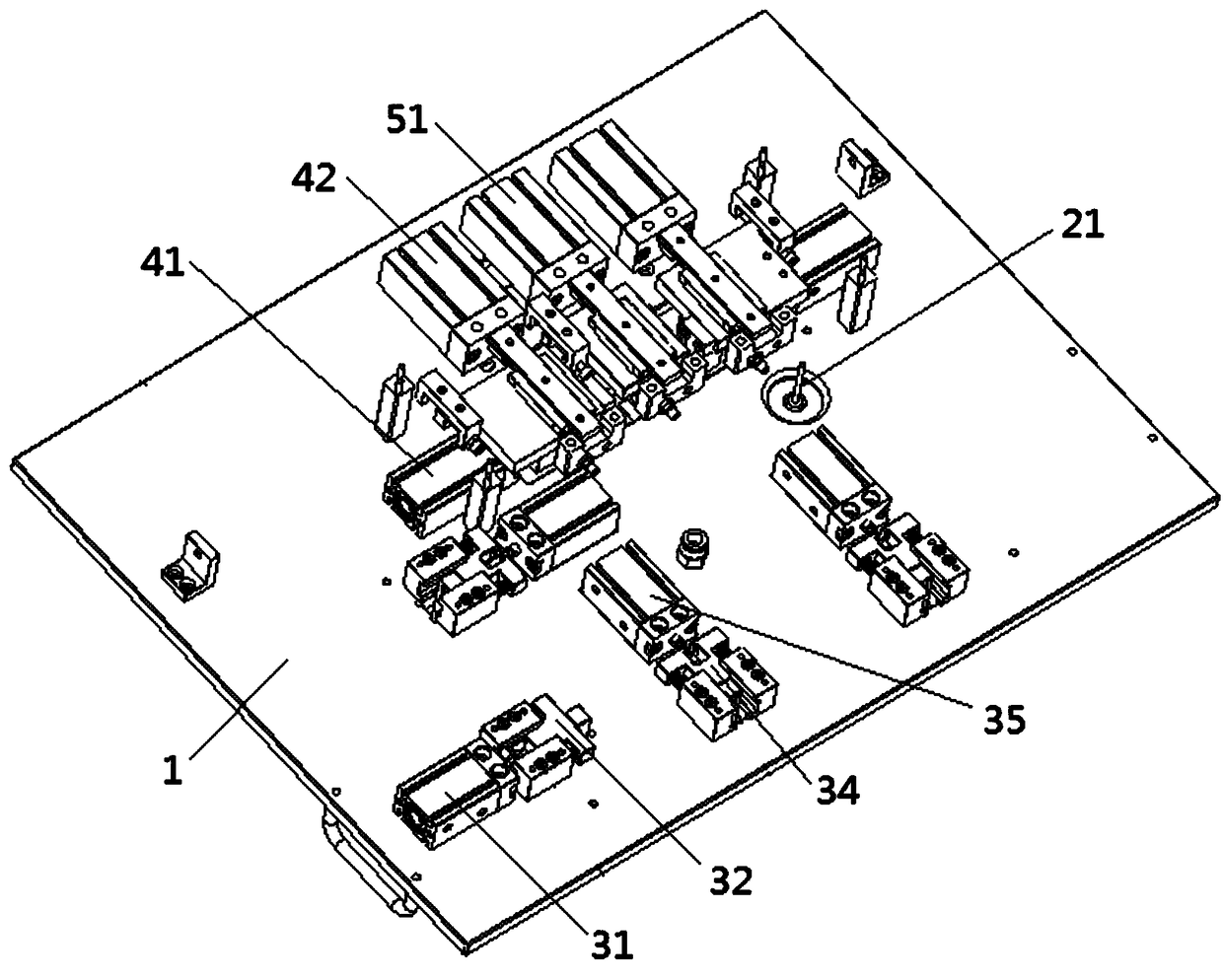

[0038] see Figure 1-6 , the present invention relates to a small-sized FPC7 bending mechanism, including an electric control box 1, a carrier device 2, a positioning device 3, a circular needle device 4, a roller device 5, and a pressing device 6. The carrier device 2 Fixedly arranged at one end of the upper surface of the electric control box body 1, the positioning device 3 is arranged on the adjacent two sides of the carrier device 2, and the circular needle device 4 and the roller device 5 are arranged side by side on one side of the carrier device 2, The pressing device 6 is arranged on the other end of the upper surface of the electric control box 1 and is located above the circular needle device 4 and the roller device 5;

[0039] The carrier device 2 is used to place the product, the positioning device 3 is used to position the product, the circular needle device 4 is used to move to the two ends of the FPC7 to form a bending datum, and the roller device 5 is used to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com