Reversible coloring photovoltaic welding belt and photovoltaic assembly

A welding ribbon and colored light technology, which is applied in the field of reversible colored photovoltaic ribbon and photovoltaic modules, can solve the problems of affecting the photoelectric conversion efficiency of photovoltaic modules, welding performance, and prone to false welding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with specific embodiment, content of the present invention is described in further detail:

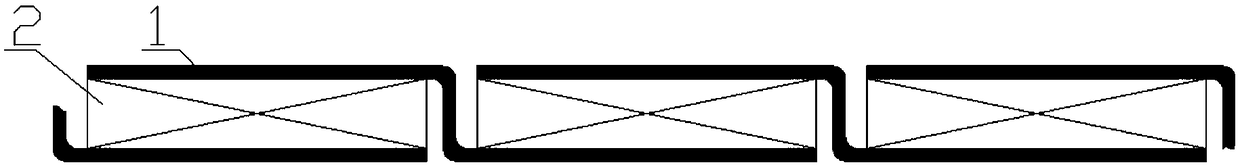

[0030] figure 1 Main diagram showing three cells connected in series using ribbons. The solar cell 2 with crystalline silicon as the substrate includes a light-receiving surface and a light-receiving surface, on which are arranged metal electrode fine grid lines and metal electrode busbar lines perpendicular to it, and the thin grid lines and the main grid lines are alternately conducted. It is used to collect the current generated by the solar cells 2 . The photovoltaic ribbon 1 is welded to the busbar to collect current and be connected in series with other cells in the subsequent process.

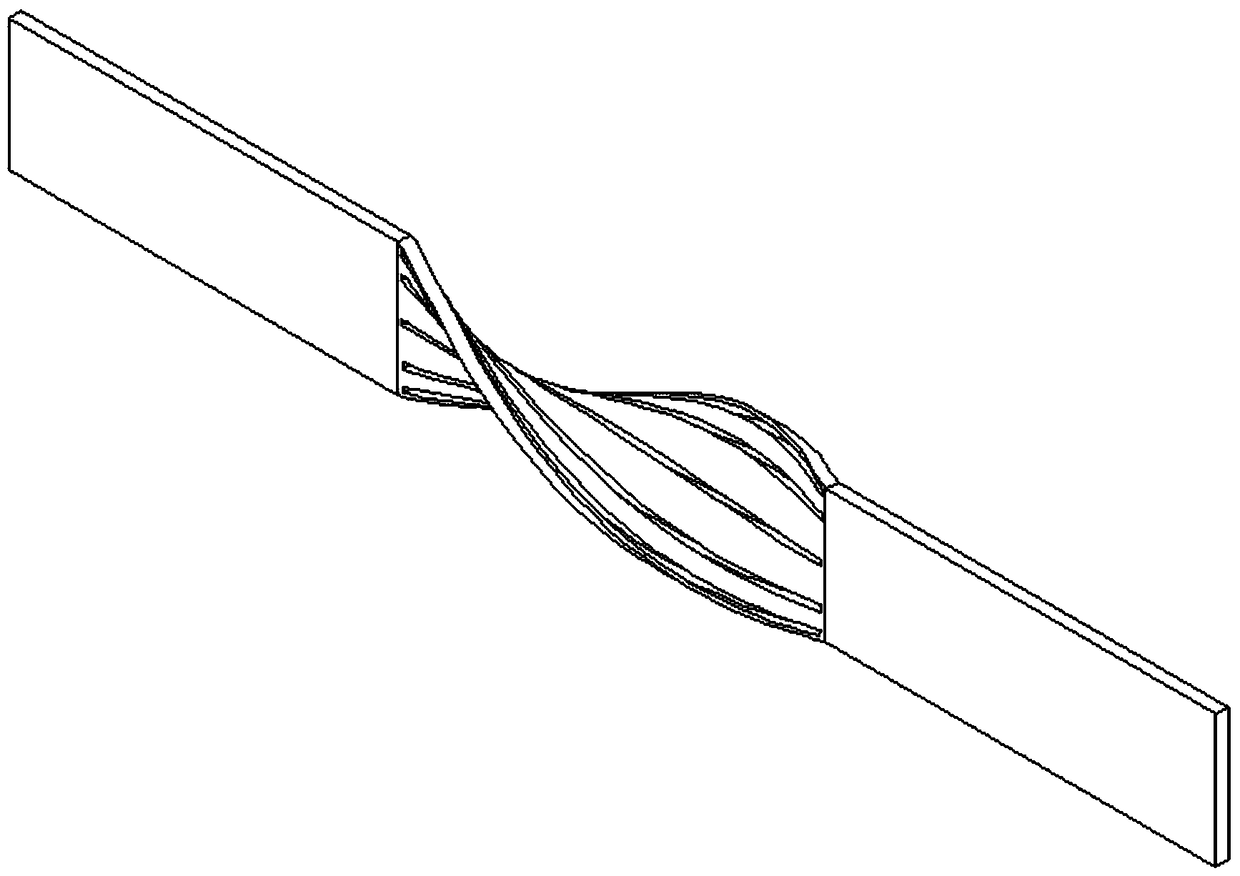

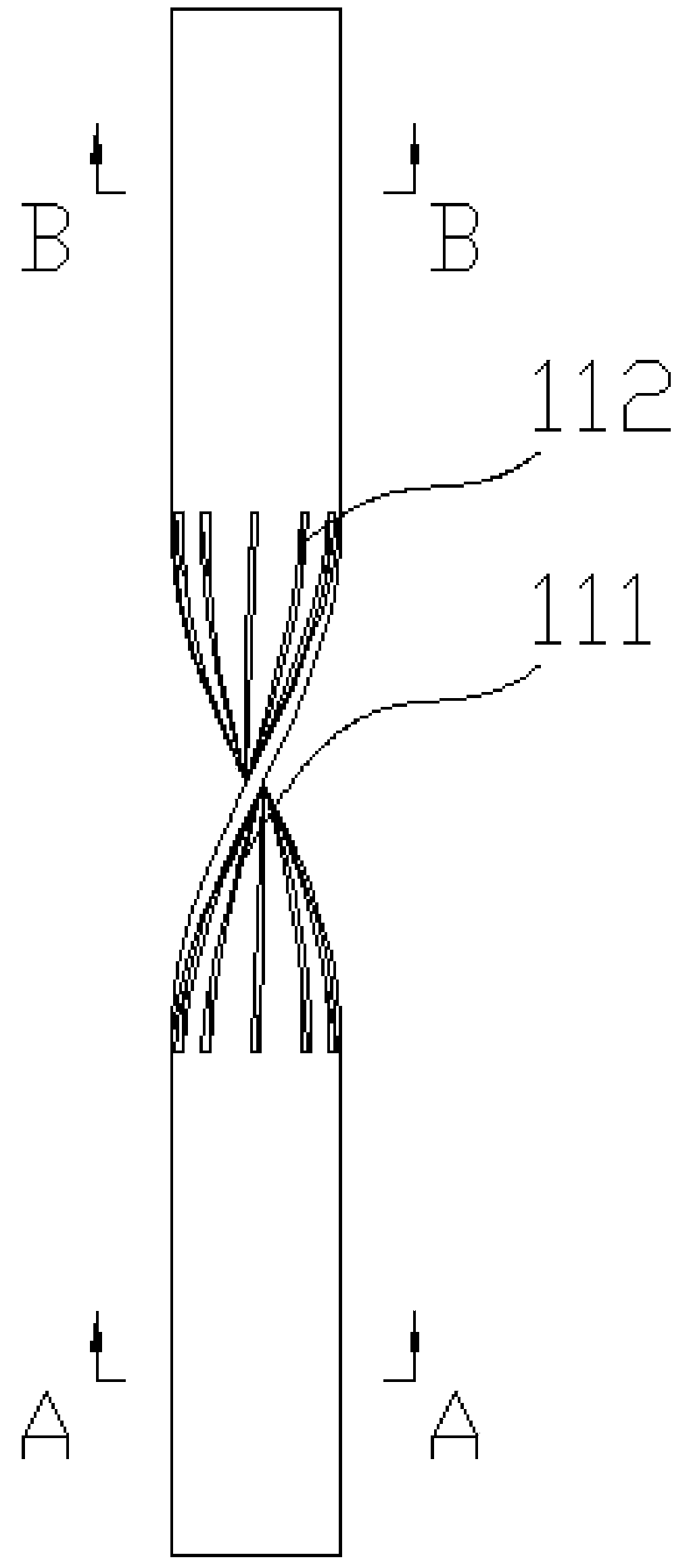

[0031] figure 2 , image 3 , Figure 4 , Figure 5 The perspective view, front view, A-A sectional view, and B-B sectional view of the twistable photovoltaic ribbon are respectively shown. The twistable colored photovoltaic ribbon 1 is composed of ribbon substr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com