Color film substrate and manufacturing method thereof

A technology for a color filter substrate and a manufacturing method, which is applied to the color filter substrate and its manufacturing field, can solve the problems of reducing the reflection effect of a liquid crystal display panel and the effect is not ideal, and achieve the effect of reducing the reflectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The word "embodiment" as used in this specification means an example, instance or illustration. Furthermore, as used in this specification and the appended claims, the article "a" or "an" may generally be construed as "one or more" unless specified otherwise or clear from the context in the singular.

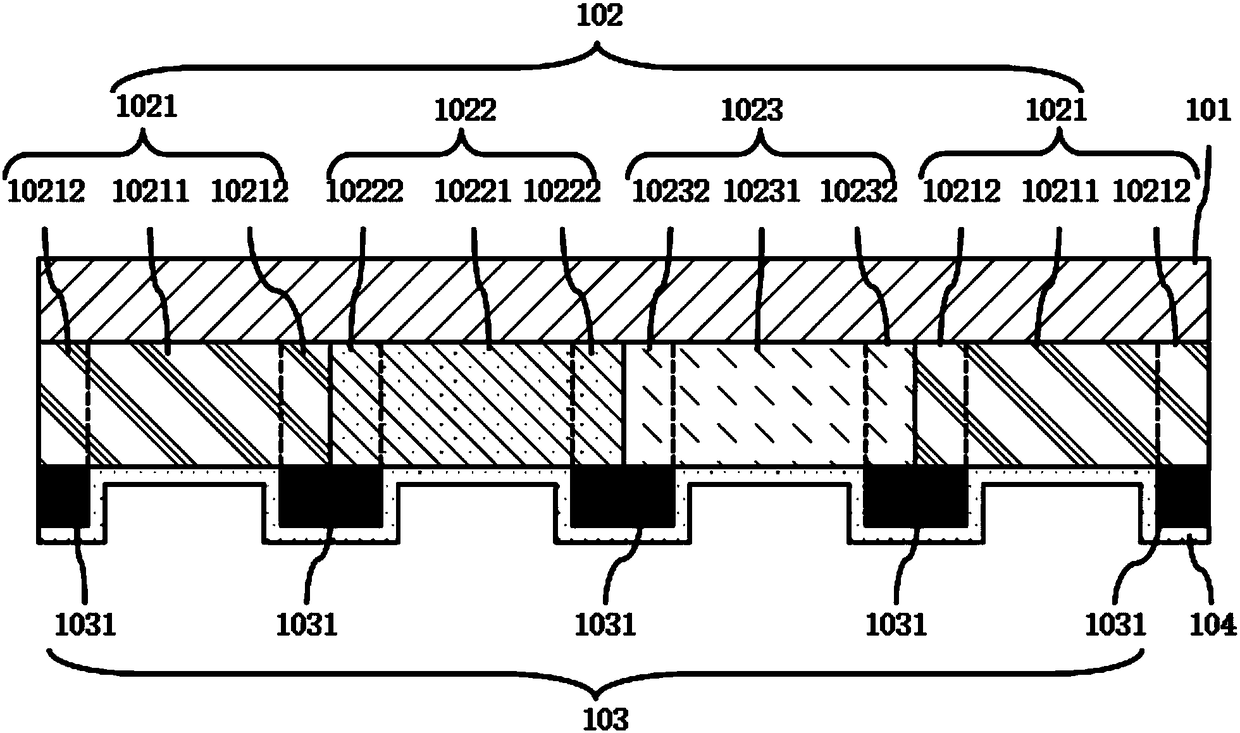

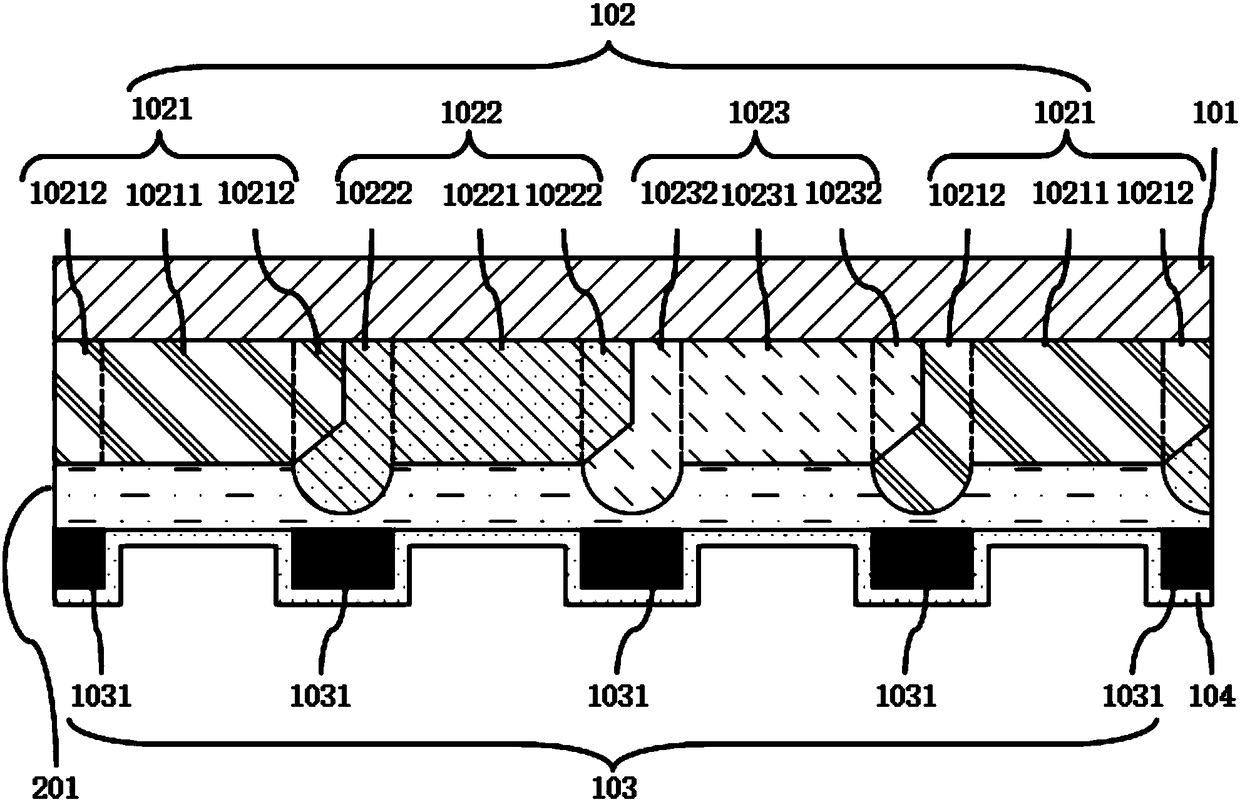

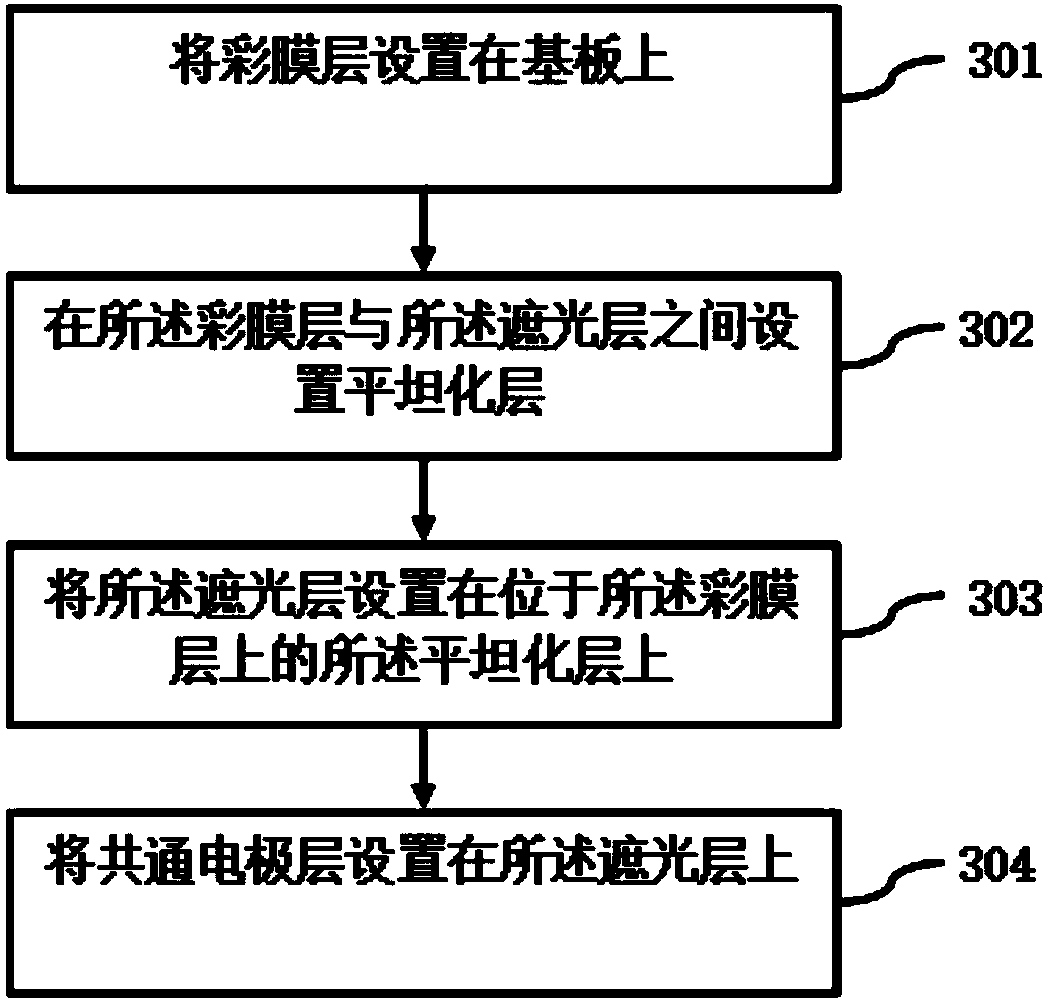

[0027] refer to figure 1 , figure 1 It is a schematic diagram of the first embodiment of the color filter substrate of the present invention. The color filter substrate of the present invention is suitable for TFT-LCD (Thin Film Transistor Liquid Crystal Display, thin film transistor liquid crystal display panel).

[0028] The color filter substrate of the present invention includes a substrate 101 , a color filter layer 102 , a light shielding layer 103 and a common electrode layer 104 . The substrate 101 is a rigid substrate or a flexible substrate.

[0029] The color filter layer 102 is arranged on the substrate 101, the color filter layer 102 includes a first colo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com