Method of preparing carbon black by pyrolyzing wasted tyres

A technology of waste tires and waste tires, which is applied in the direction of fibrous fillers, etc., can solve the problems of limited commercial promotion, and achieve the effects of good economy, high commercial promotion ability, and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific implementation manner of the present invention will be described in detail below in conjunction with the technical solutions.

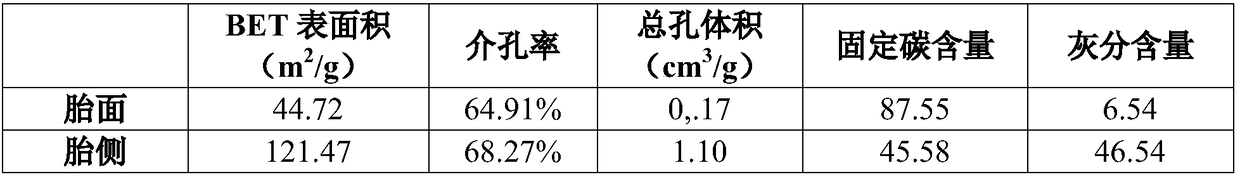

[0020] The invention discloses a method for preparing carbon black by pyrolysis of waste tires. The waste tires are firstly removed by a bead cutting machine to remove bead steel wires, and then divided into two parts, the tread and the sidewall, by an automatic cutting device. The tread part is crushed by the crusher and enters the pyrolysis system. The pyrolysis device is a fixed bed, the pyrolysis temperature is 500°C, the heating rate is 10°C / min, the residence time: 30min, and the carrier gas type: N 2 , Carrier gas flow rate: 100ml / min. The pyrolyzed carbon black passes through the magnetic separator to separate the carbon black from the tread steel wire, and the pyrolytic carbon black can be utilized; the sidewall part is crushed by the crusher and then enters the pyrolysis system. The pyrolysis device is a fixed bed, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com