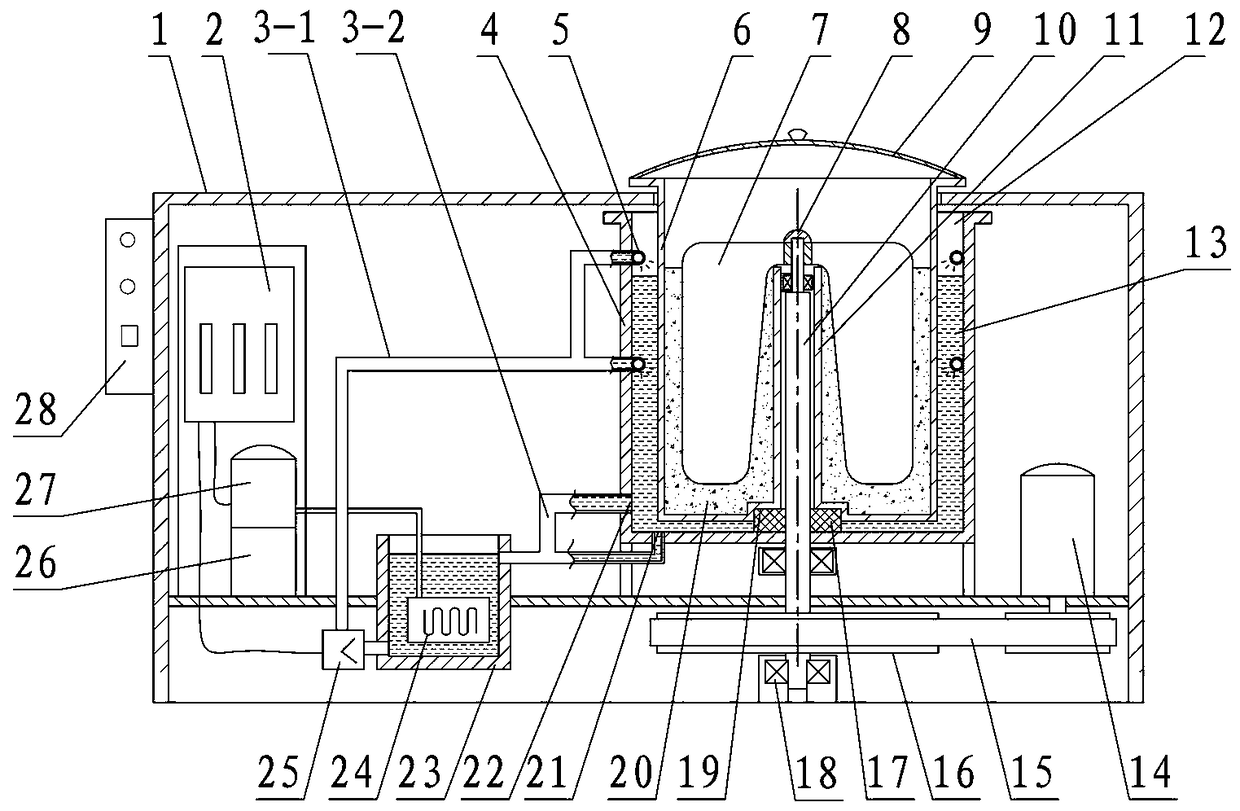

Separable anti-cylinder freezing ice cream machine

An ice cream machine and separate technology, applied in the field of cold food production equipment, can solve the problems of slow cooling speed of the inner cylinder, high production cost, and easy occurrence of freezing cylinders, etc., achieve fast cooling conduction, delicate products, and improve production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

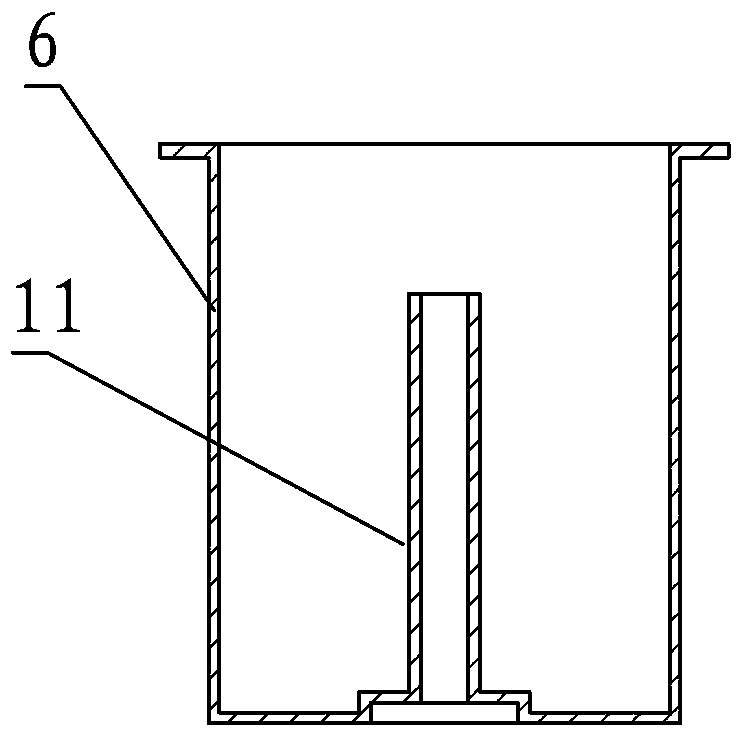

Examples

Embodiment 2

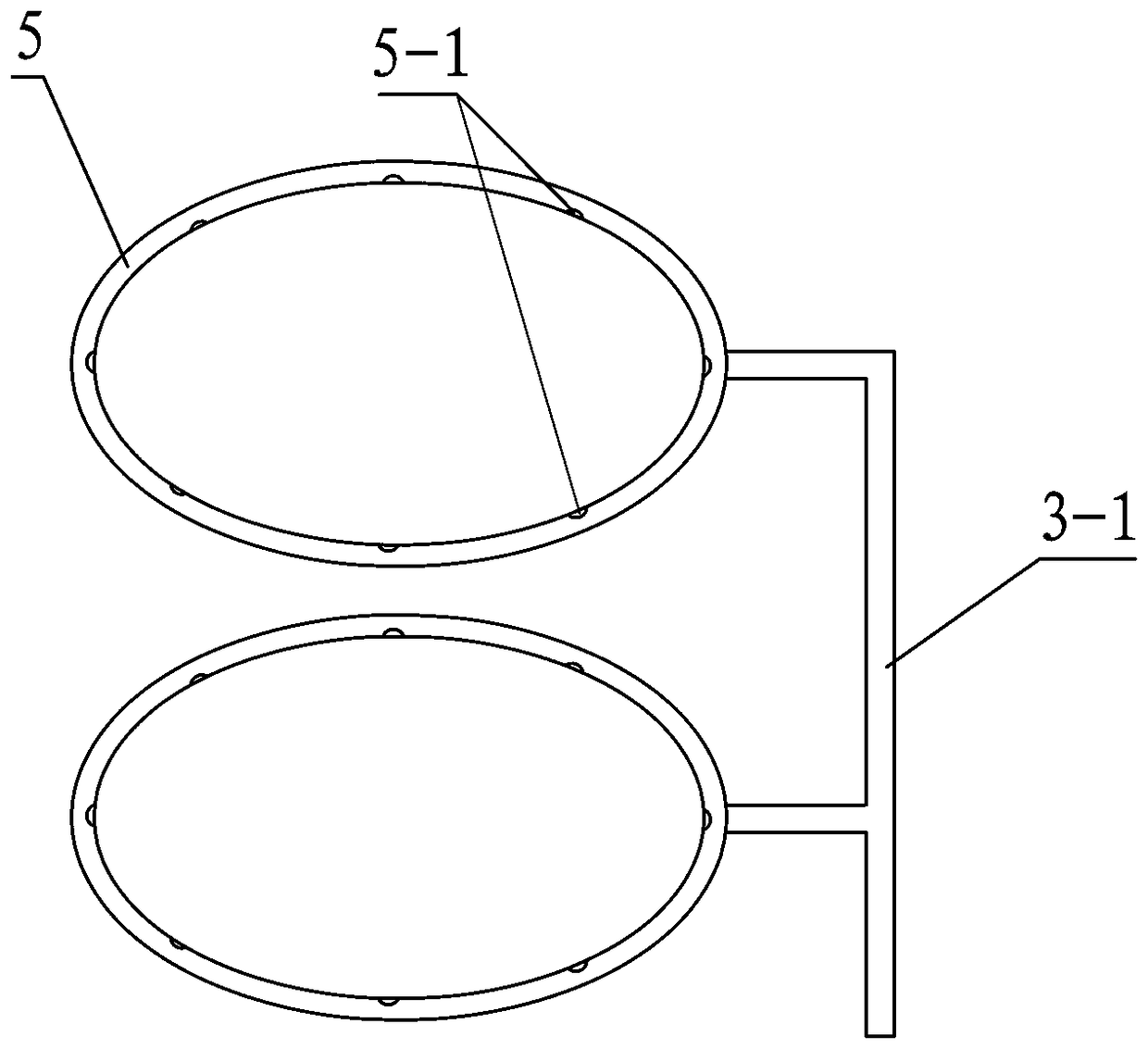

[0030] Embodiment two, such as Figure 5 As shown, a detachable antifreeze cylinder ice cream machine is improved on the basis of Embodiment 1, and two sets of refrigeration containers are used in the rack, and the refrigeration containers are still made of outer barrels and inner barrels. The corresponding coolant circulation pipelines with coolant storage pool, coolant circulation pump 25 and coolant spray pipes are connected, and two sets of coolant circulation pipelines pass through the upstream conduit 3-1 with branch pipes and return The liquid conduit 3-2 is connected to the same cooling liquid storage pool in parallel, and the cooling state of the cooling container can be controlled respectively by the electric control device of the distribution box. The two groups of refrigerated containers can be respectively matched and connected with a transmission mechanism and a driving motor.

Embodiment 3

[0031] Embodiment three, such as Figure 6 As shown, a detachable antifreeze cylinder ice cream machine, with reference to the second embodiment, the cooling container in the frame is set to four, and the corresponding cooling liquid storage pool, cooling liquid circulation pump 25 and cooling liquid circulation pump 25 are respectively connected to each other. The coolant circulation pipeline of the liquid spray pipe, and each group of coolant circulation pipelines are also connected in parallel to the same coolant storage through the coolant upflow conduit 3-1 and the return flow conduit 3-2 with branch pipes pool. Each group of refrigerated containers can be respectively matched and connected with a transmission mechanism and a driving motor.

[0032] The spray pipes in the second and third embodiments can be annular pipes or spiral pipes, and the spray ports are arranged on the side walls of the annular pipes.

[0033] The above-mentioned ice cream machine using multiple...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com