Flexible heat exchanger and manufacturing method thereof

A soft heat exchanger and manufacturing method technology, applied in household refrigeration equipment, lighting and heating equipment, household appliances, etc., to achieve the effects of reducing workload, improving refrigeration speed, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

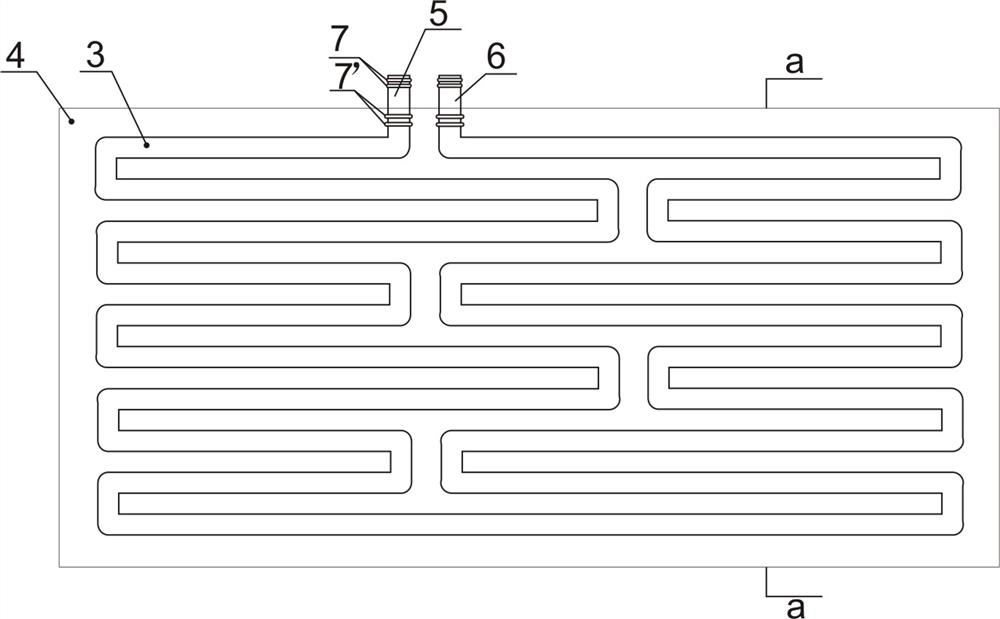

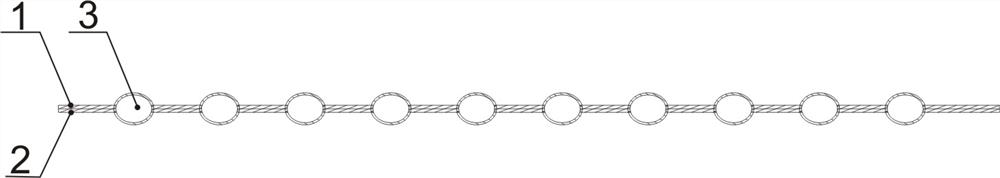

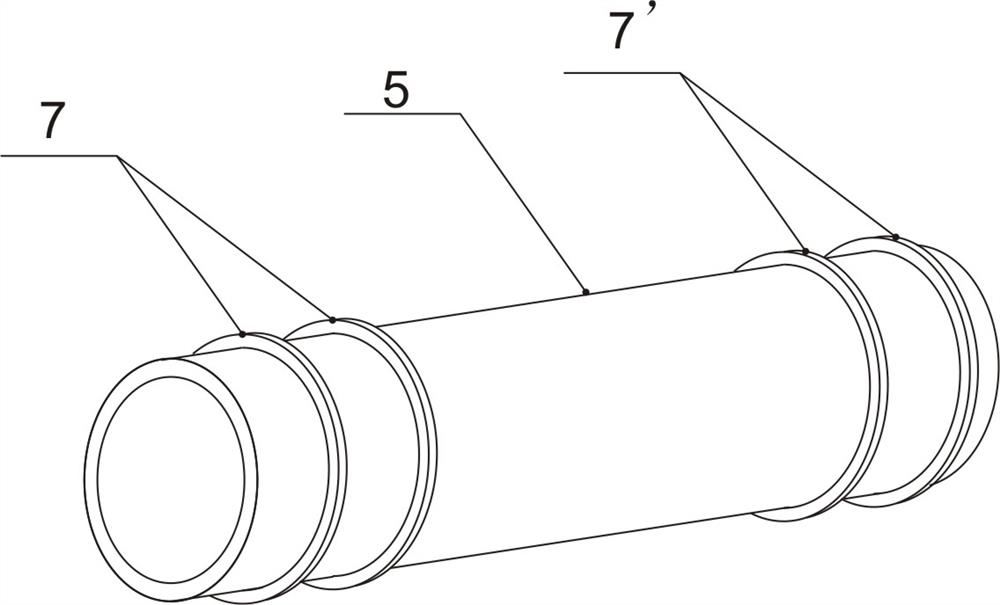

[0014] Such as figure 1 , figure 2 As shown, the present invention includes a surface plastic film (1) and a bottom plastic film (2) of the same size, and the surface plastic film and the bottom plastic film are thermally melted at a certain distance to form a bonding area (4) and a liquid channel (3) ), the liquid channel is connected as a whole. In order to facilitate liquid circulation, the distance between the liquid channels is generally between 5mm and 10mm, and the width of the liquid channels is between 12mm and 15mm in the planar state, so as to ensure that the liquid channels form a channel with a diameter of 8mm to 10mm when in use. The inlet and outlet ends of the liquid channel are located on the side of the plastic film, and conduit joints (5) and (6) are fixedly arranged on the inlet and outlet ends respectively. In order to improve the firmness of the catheter joint, anti-off rings (7) and (7') are respectively provided at the two ends of the outer side of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com