Compound preservative for fresh-cut fruits and vegetables and use method thereof

A composite fresh-keeping, fruit and vegetable technology, applied in the direction of fruit and vegetable preservation, protection of fruits/vegetables with a coating protective layer, application, etc., can solve the problems of deterioration, dehydration, oxidation and other problems in the process of fresh-cut fruits and vegetables, and achieve slow fruit and vegetable tissue and structure Effects of aging, prevention of oxidative browning, and good film-forming properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

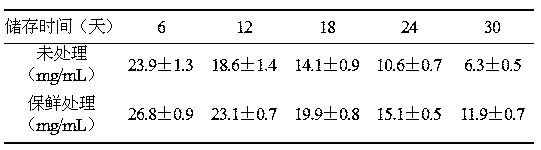

Examples

Embodiment 1

[0026] Fresh Cut Apple Processing

[0027] Preparation of soaking solution: Add 8g of low-viscosity chitosan (viscosity 100-200mPa s, 1%, 20°C) and 20g of β-cyclodextrin to 1000ml of deionized water, heat to 55°C and stir to dissolve, add 10g of cinnamon essential oil and seal it at 55°C Stir at ℃ for 4 hours, then add 20g of ascorbic acid to dissolve and obtain soaking solution.

[0028] Soaking: Soak the prepared fresh-cut apples in the above 55°C soaking solution for 2 minutes, take them out, drain the water, and place them in a ventilated and dry place indoors for 1 hour to cool down to room temperature, and the surface is dry without obvious moisture.

[0029] Spray film: Mix konjac glucomannan and carrageenan at a ratio of 5.5:4.5, add deionized water to adjust pH = about 10, heat to 85°C and stir to dissolve to make a 2% mixed gel solution. Cool down to 70°C and evenly spray the gel solution onto the surface of soaked fruits and vegetables.

[0030] Air-drying: After ...

Embodiment 2

[0033] Fresh Cut Pear Processing

[0034]Preparation of soaking solution: Add 10g of low-viscosity chitosan (viscosity 100-200mPa s, 1%, 20°C) and 20g of β-cyclodextrin to 1000ml of deionized water, heat to 55°C and stir to dissolve, add 10g of cinnamon essential oil and seal it at 55°C Stir at ℃ for 4 hours, then add 10 g of ascorbic acid to dissolve to obtain soaking solution.

[0035] Soaking: Soak the prepared fresh-cut pears in the above 55°C soaking solution for 2 minutes, take it out, drain the water, and place it in a ventilated and dry place indoors for 2 hours to cool down to room temperature, and the surface is dry without obvious moisture.

[0036] Spray film: Mix konjac glucomannan and carrageenan at a ratio of 5.5:4.5, add deionized water to adjust pH = about 10, heat to 85°C and stir to dissolve to make a 2% mixed gel solution. Cool down to 70°C and evenly spray the gel solution onto the surface of soaked fruits and vegetables.

[0037] Air-drying: After spray...

example 3

[0040] Fresh Cut Melon Processing

[0041] Preparation of soaking solution: Add 10g of low-viscosity chitosan (viscosity 100-200mPa s, 1%, 20°C) and 20g of β-cyclodextrin to 1000ml of deionized water, heat to 55°C and stir to dissolve, add 10g of cinnamon essential oil and seal it at 55°C Stir at ℃ for 4 hours, then add 10 g of ascorbic acid to dissolve to obtain soaking solution.

[0042] Soaking: Soak the prepared fresh-cut melon in the above 55°C soaking solution for 4 minutes, take it out, drain the water, and place it in a ventilated and dry place indoors for 2 hours to cool down to room temperature, and the surface is dry without obvious moisture.

[0043] Spray film: Mix konjac glucomannan and carrageenan at a ratio of 5.5:4.5, add deionized water to adjust pH = about 10, heat to 85°C and stir to dissolve to make a 2% mixed gel solution. Cool down to 70°C and evenly spray the gel solution onto the surface of soaked fruits and vegetables.

[0044] Air-drying: After spr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com