Vertical connection structure of photovoltaic module and photovoltaic module thereof

A vertical connection structure and photovoltaic module technology, applied in photovoltaic power generation, photovoltaic modules, electrical components, etc., can solve the problems of waste, easy dust accumulation, burrs and protrusions, etc., achieve easy assembly and fastening, and improve connection tightness , the effect of a good protective structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Below in conjunction with specific embodiment, content of the present invention is described in further detail:

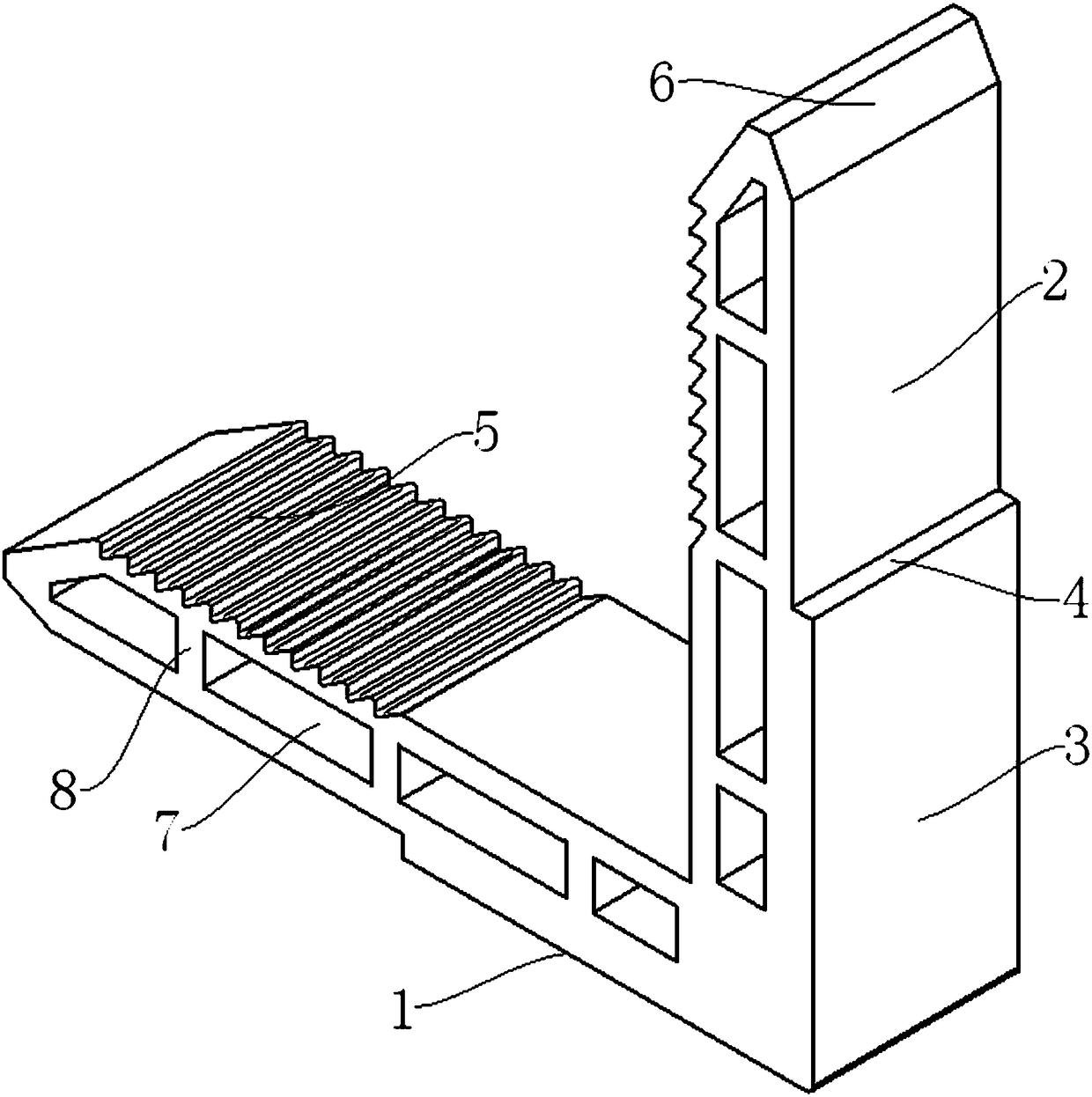

[0037] In order to achieve the purpose of the present invention, a vertical connection structure of a photovoltaic module includes: a corner code 1 with a connecting arm, a sawtooth surface 5, and a seam surface 4; Along the length direction, it is divided into an insertion section 3 and a connecting section 2; the serration surface 5 is located on the insertion section 3, and the serrations on the serration surface 5 have a steep slope surface and a gentle slope surface, and the steep slope surface faces the direction of the connection section 2; the mouth surface 4, Located at the junction of the insertion section 3 and the connection section 2, the seam surface 4 is perpendicular to the length direction of the insertion section 3 and the connection section 2; The end contacts; the corner protector has an L-shaped groove 13 in the length direction, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com