Modular stator and wind generating set

A modular and generator technology, which is applied in wind power generation, electric components, windings, etc., can solve the problems of rising copper weight of generators, difficulty in ensuring welding quality, and weak welding, so as to improve the problem of unbalanced resistance and facilitate replacement and maintenance, improving performance and longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In order to enable those skilled in the art to better understand the present invention, specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

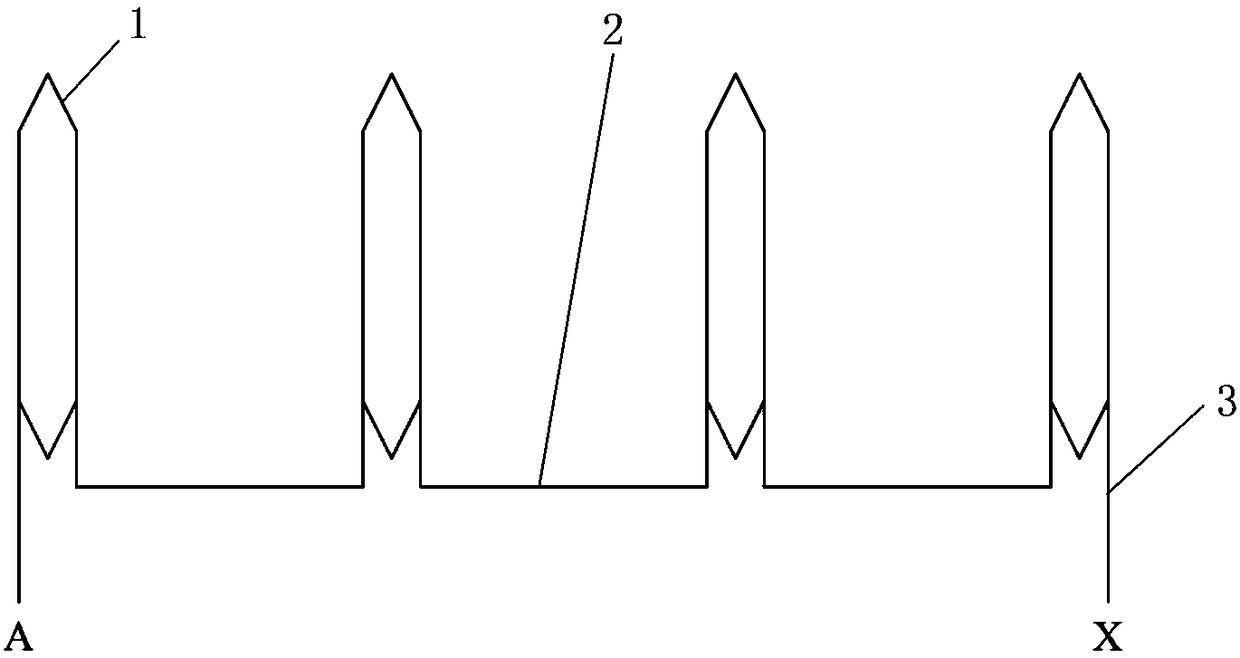

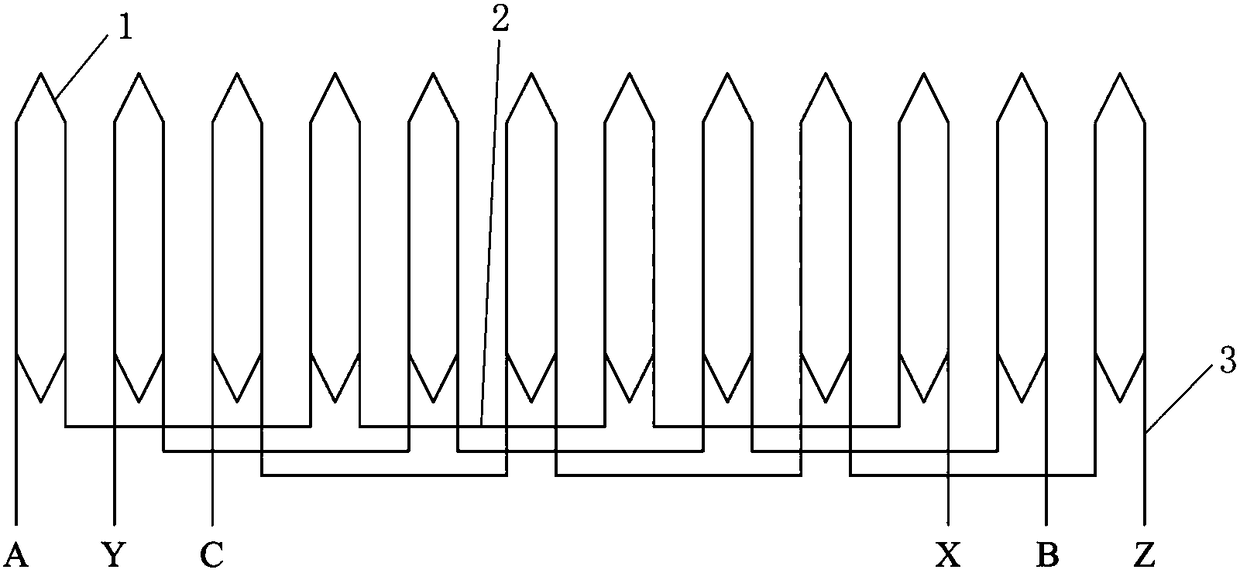

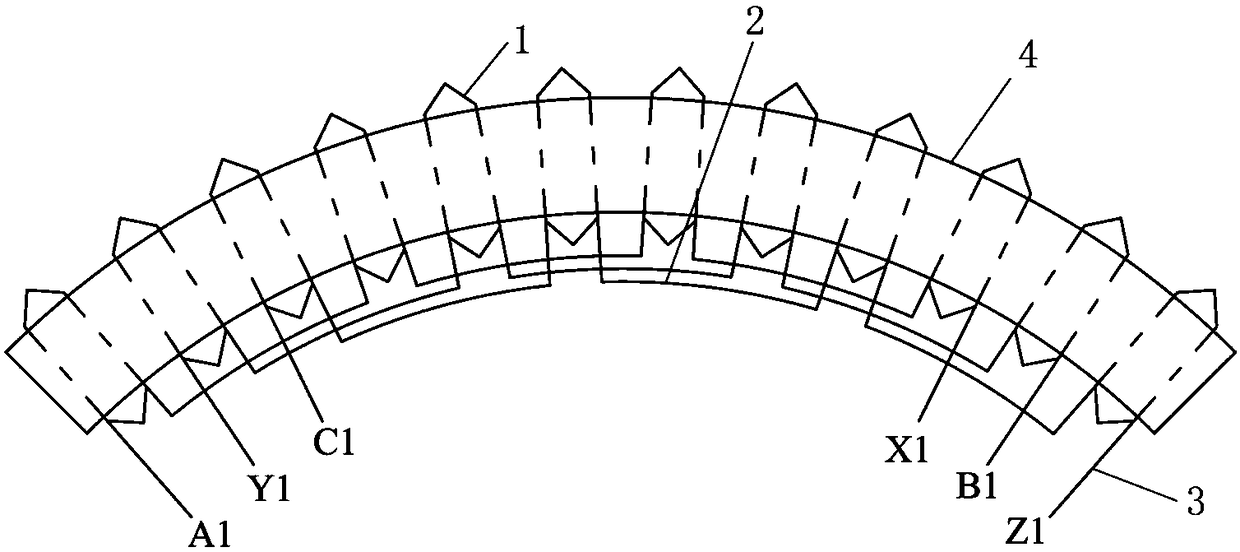

[0047] refer to Figure 1 to Figure 6 , shows the modular stator of the electric machine with concentrated windings. Such as figure 1 As shown, each phase concentrated winding has two phase belts, which are A-phase belt and X-phase belt. Each phase concentrated winding can have a plurality of coils 1, and each coil 1 is connected to each other through an inter-coil lead wire 2. The A-phase belt and the X-phase belt are drawn from the two outermost coils 1, and are connected between the A-phase belt and the X-phase belt. The phase belt and the coil 1 are connected through the lead wire 3 between the coil and the end ring. The inter-coil lead wire 2 is connected to each coil 1 by welding. Such as figure 2 As shown, a schematic diagram of the wiring expa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com