Gradient reflection type light guiding lamp box

A light box and gradient technology, applied in the field of gradient reflection light guide light boxes, can solve the problems of waste of manpower and material resources, inability to make ultra-thin light boxes, and high requirements for light box thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

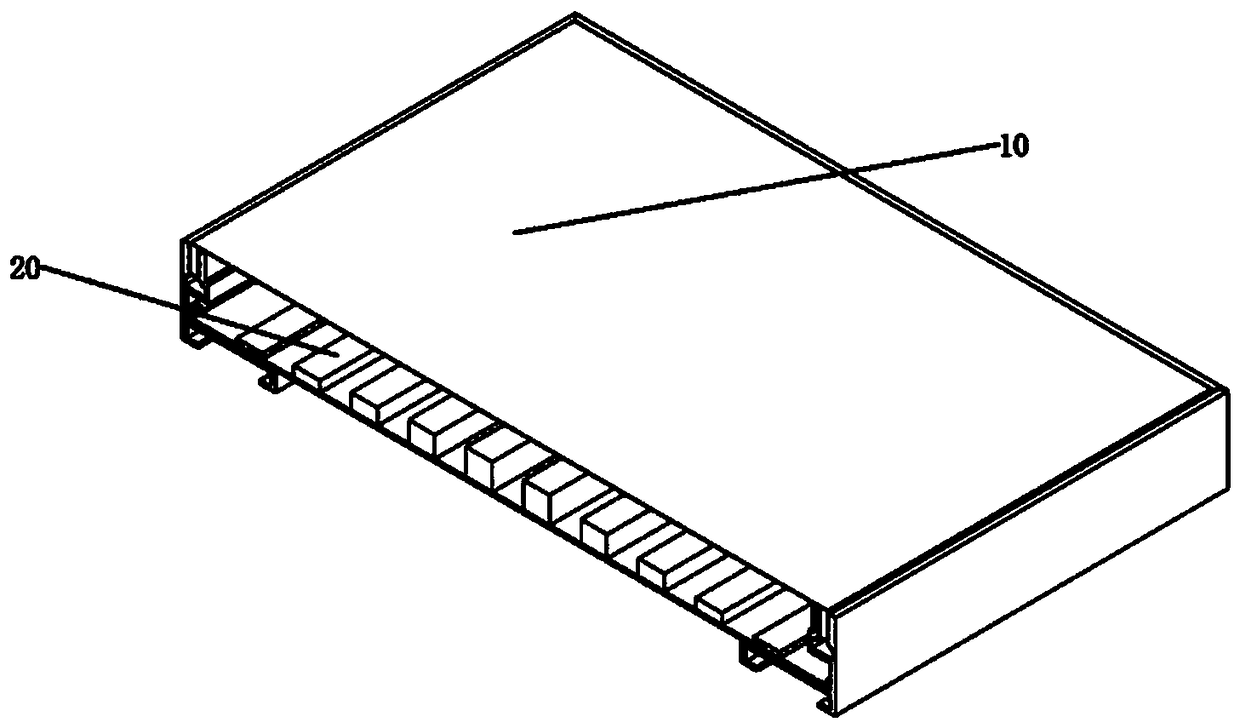

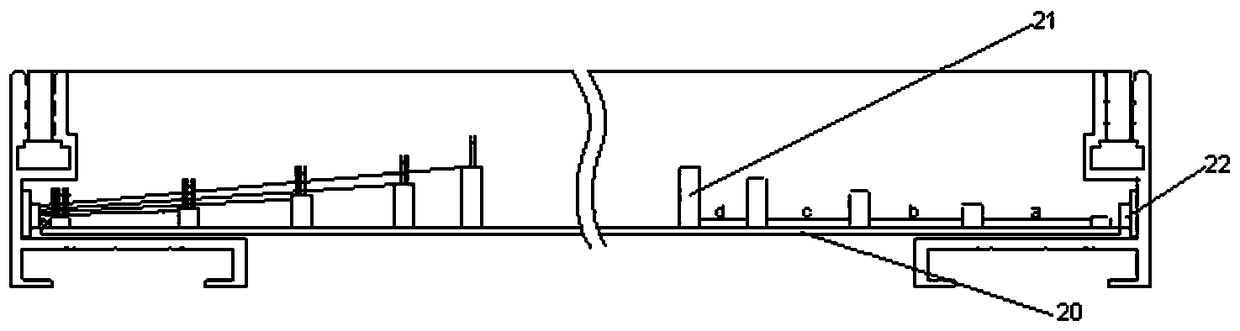

[0028] The gradient reflective light guide light box of the present invention comprises a light box body 10, a plurality of reflective panels 20 are arranged in the light box box 10, black reflectors 21 arranged in gradients are arranged on the reflective panel 20, and on both sides of the reflective panel 21 An LED light source 22 is provided on the side.

[0029] In the present invention, the black reflector 21 is from near to far away from the LED light source 22, and the size of the black reflector 21 is from small to large; From low to high; the distance between the black reflectors 21 is from near to far from the LED light source 22, and the distance between the black reflectors 21 is a>b>c>d.

[0030] In the present invention, the black reflector 21 is printed on the reflective panel 20; the shape of the black reflector 21 is a rectangle.

Embodiment 2

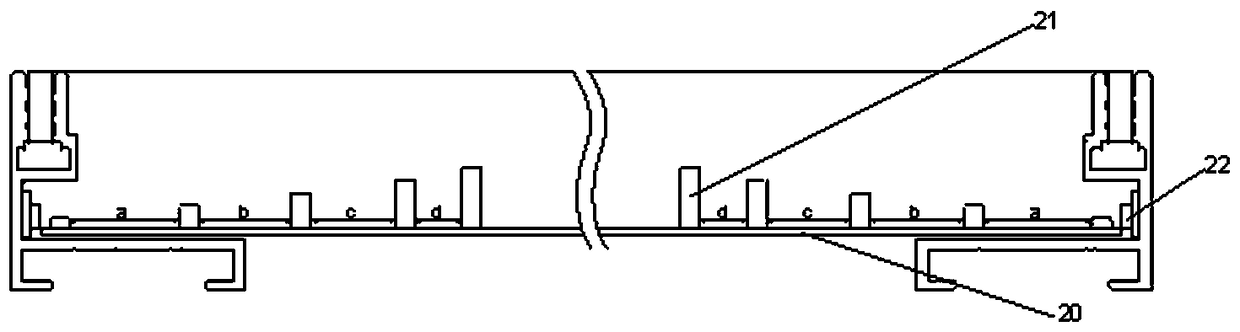

[0032] The gradient reflective light guide light box of the present invention comprises a light box body 10, a plurality of reflective panels 20 are arranged in the light box box 10, black reflectors 21 arranged in gradients are arranged on the reflective panel 20, and on both sides of the reflective panel 21 An LED light source 22 is provided on the side.

[0033] In the present invention, the black reflector 21 is from near to far away from the LED light source 22, and the size of the black reflector 21 is from small to large; From low to high; the distance between the black reflectors 21 is from near to far from the LED light source 22, and the distance between the black reflectors 21 is a>b>c>d.

[0034] In the present invention, the black reflector 21 is printed on the reflective panel 20; the shape of the black reflector 21 is cylindrical.

Embodiment 3

[0036] The gradient reflective light guide light box of the present invention comprises a light box body 10, a plurality of reflective panels 20 are arranged in the light box box 10, black reflectors 21 arranged in gradients are arranged on the reflective panel 20, and on both sides of the reflective panel 21 An LED light source 22 is provided on the side.

[0037] In the present invention, the black reflector 21 is from near to far away from the LED light source 22, and the size of the black reflector 21 is from small to large; From low to high; the distance between the black reflectors 21 is from near to far from the LED light source 22, and the distance between the black reflectors 21 is a>b>c>d.

[0038] In the present invention, the black reflector 21 is printed on the reflective panel 20; the shape of the black reflector 21 is a triangle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com