Tester capable of simulating track in braking state

A kind of rutting test and state technology, which is applied in the direction of material inspection products, etc., can solve the problems of not being able to meet the needs of one machine for multiple purposes, inconsistent road surface force conditions, inconsistent horizontal tangential force, etc. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

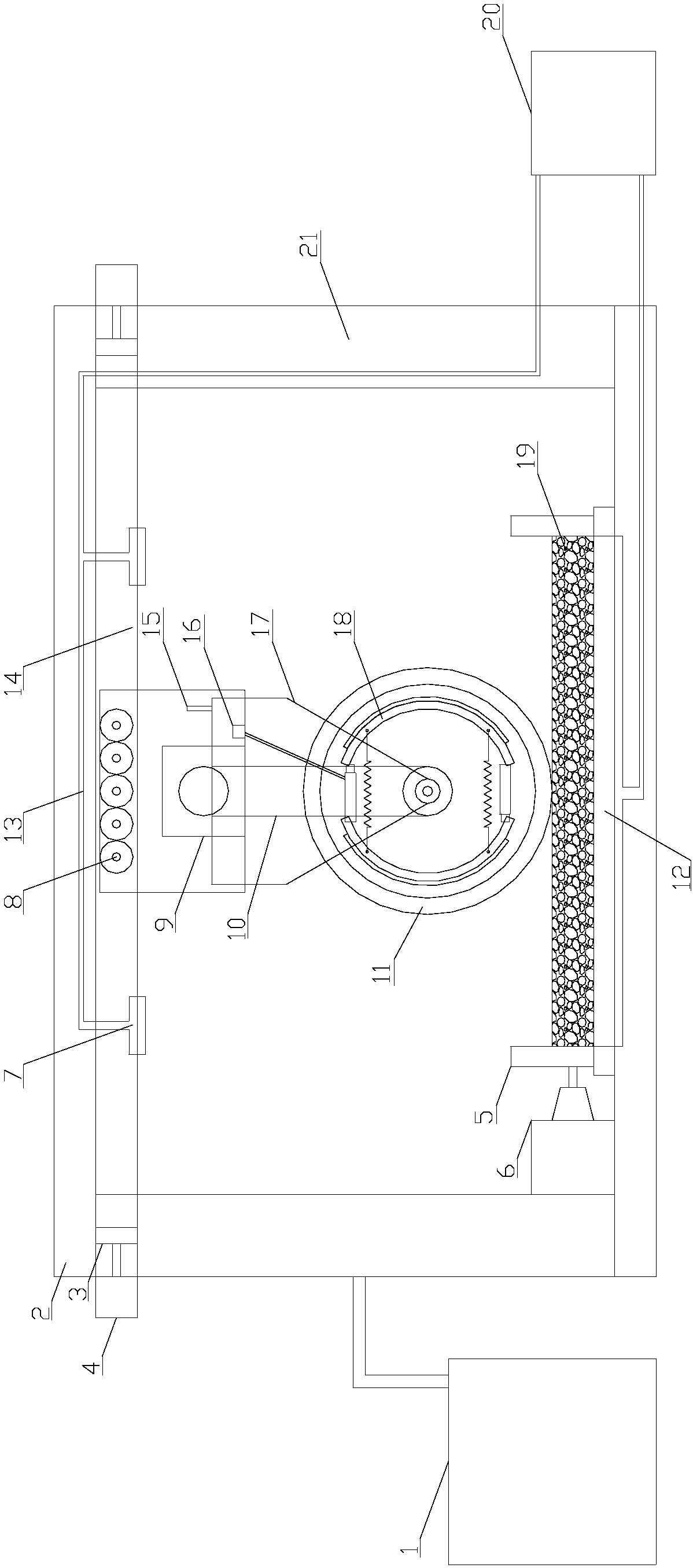

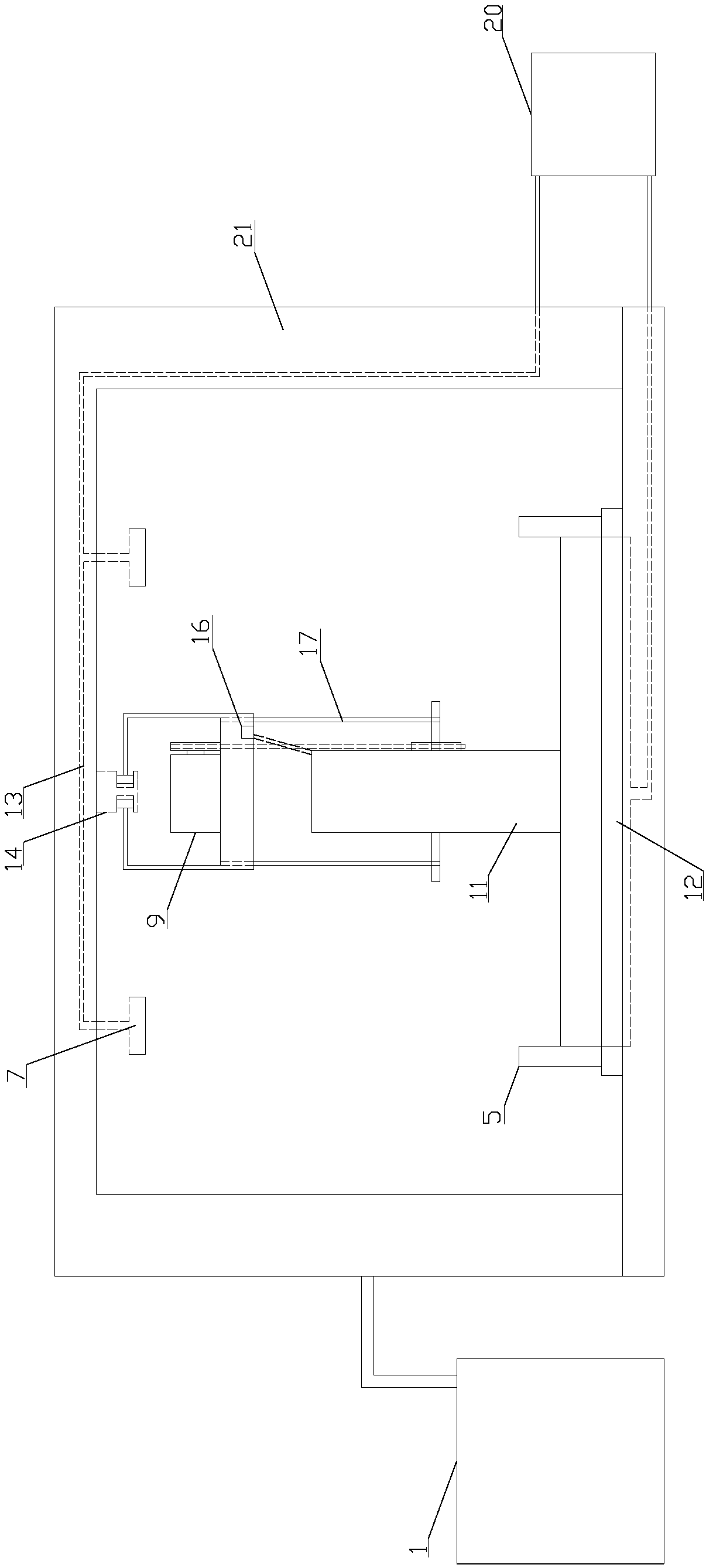

[0026] 1. The basic structure of the rutting tester under the simulated braking state

[0027] Such as figure 1 As shown, the rutting tester under the simulated braking state of the present invention includes a test main control measurement system transmitted by a data line; a bracket device; a drive device; a wheel set device; a pressure device; a simulated rainfall circulation device; a temperature control system.

[0028] The test main control measurement system 1 is located outside the test instrument, controlled by a computer, and uses sensors to transmit data to the test measurement system through data lines. The temperature control system is located inside the test chamber.

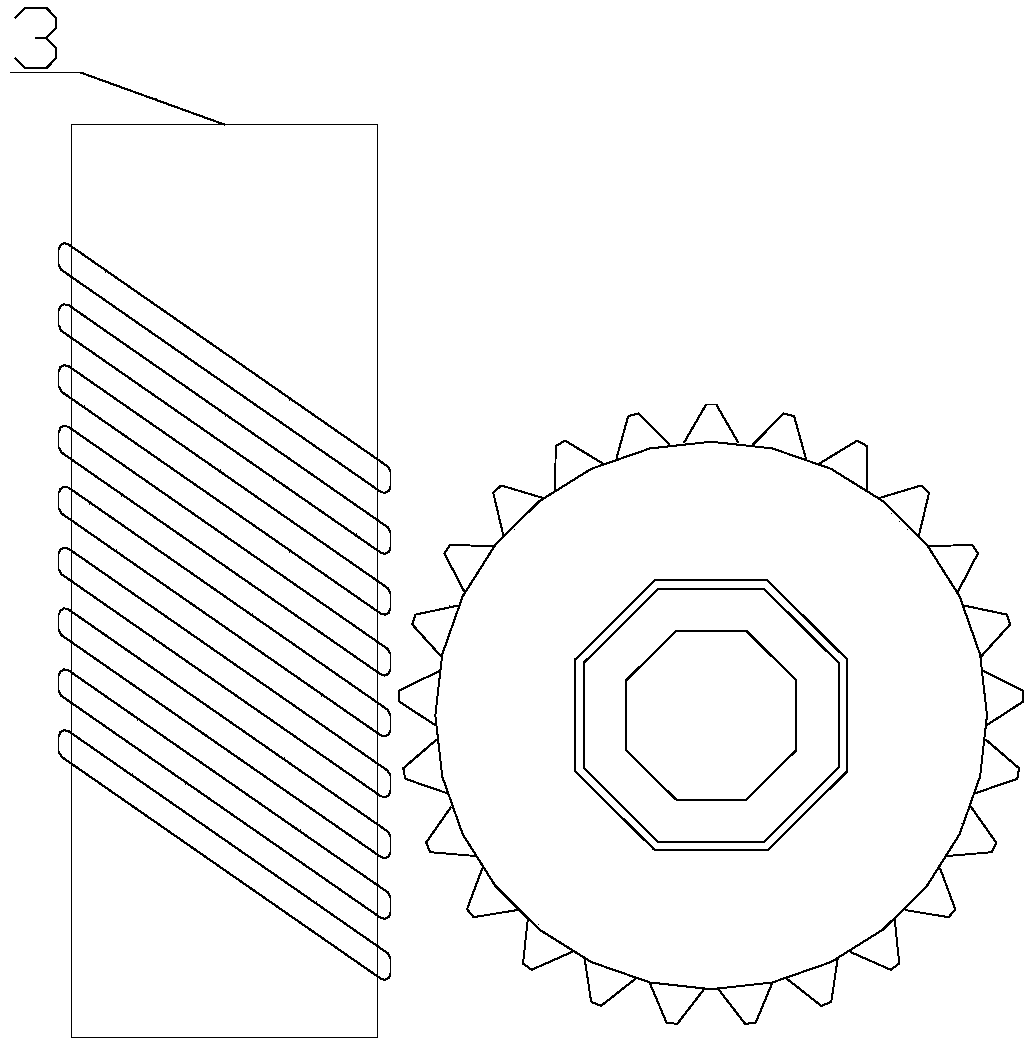

[0029] The support device includes a test stand 12 , a guide rail 14 and a wheel frame 17 . The test bench is located at the bottom of the instrument and consists of a hydraulic device, a test platform and a sliding push plate; the left sliding push plate is connected to the hydraulic device. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com