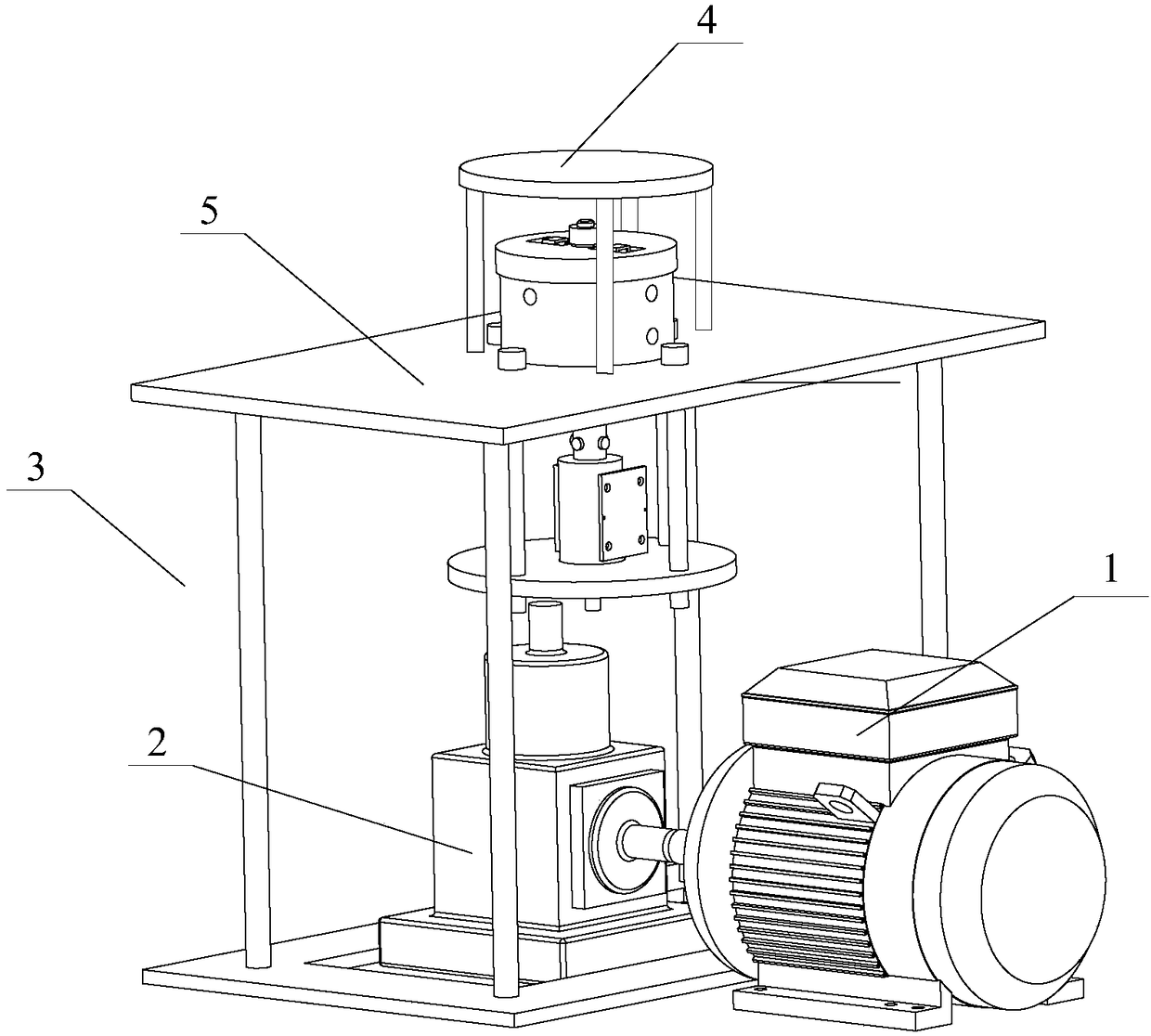

Vertical multifunctional friction-wear testing machine

A friction and wear test, multi-functional technology, applied in the direction of testing wear resistance, measuring devices, instruments, etc., can solve the problems of low operation stability, low test accuracy, short normal working life, etc., and achieve the effect of high coaxial accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

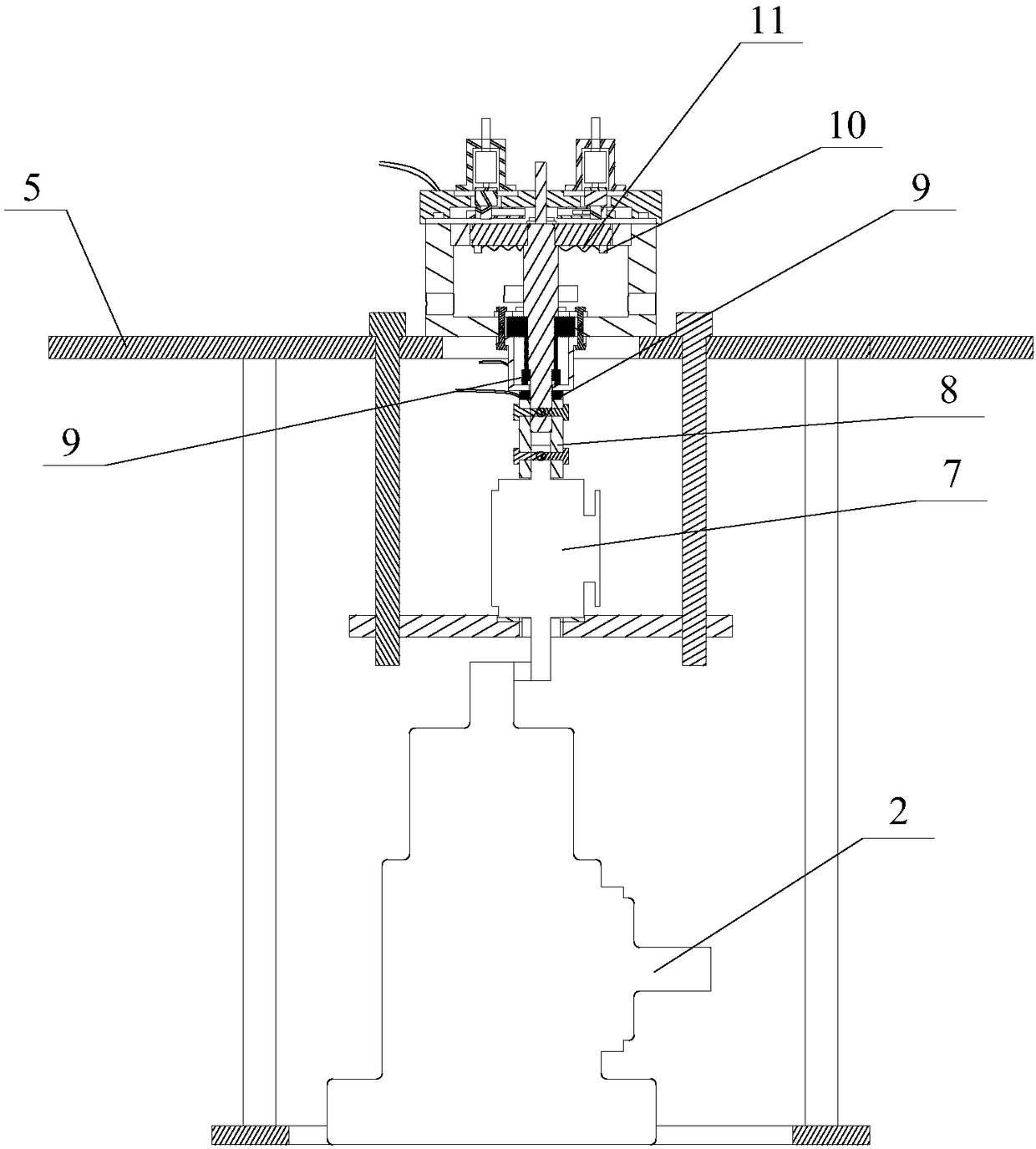

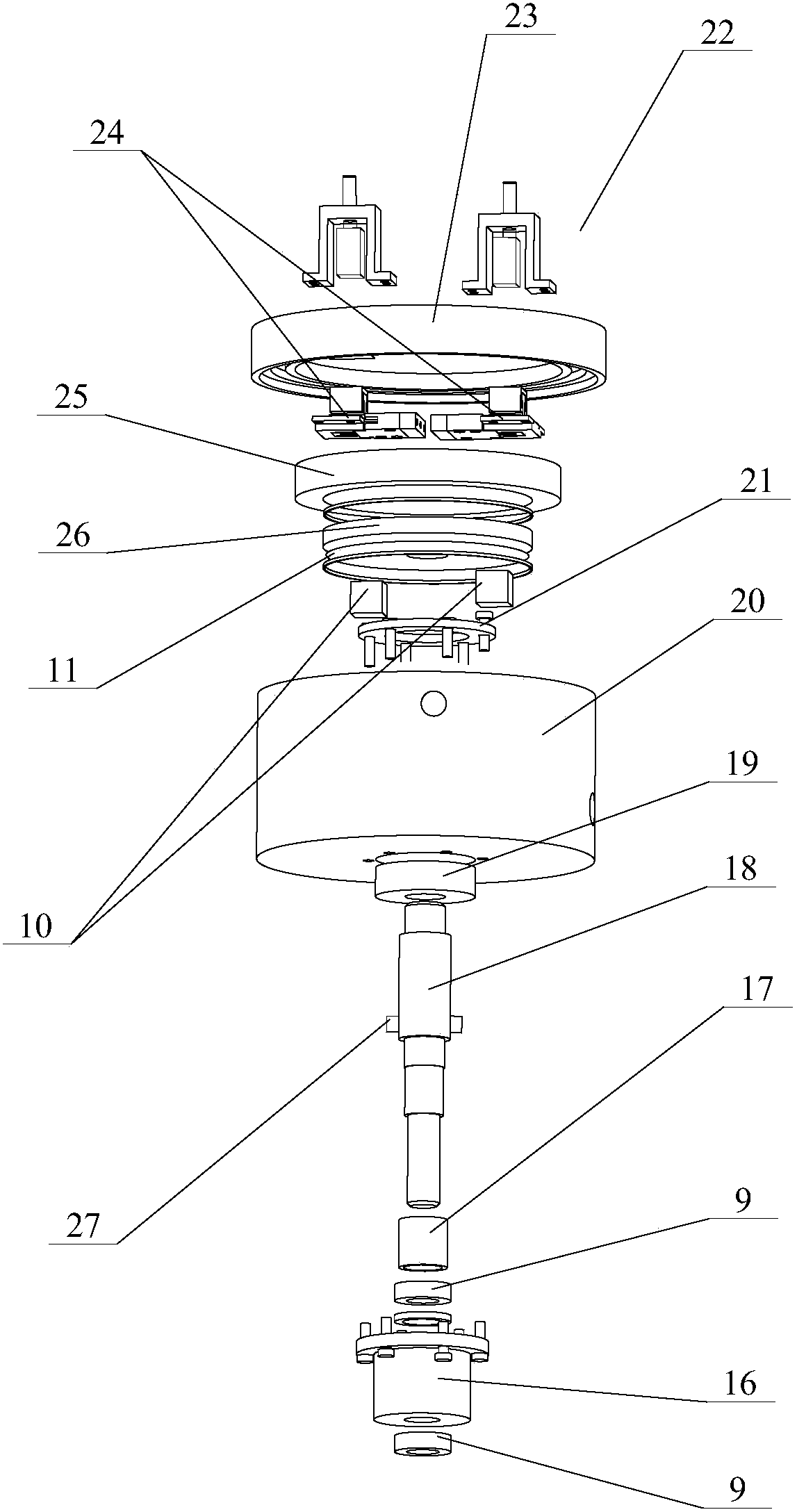

[0052] 2. The present invention adopts two kinds of schemes in the friction test mode, one adopts the direct test scheme of the load cell, and the measurement is more accurate, such as figure 2 with Figure 8 Shown embodiment one and embodiment three; Another kind is to adopt the scheme that obtains friction force again after testing the friction pair torque, avoided the impact of vibration and heat on the test, such as Figure 7 Shown embodiment two;

[0053] 3, in the test equipment of the present invention, a vibrator has been applied as a vibration excitation device, and under the influence of vibration, the friction and wear test test work of the friction pair can be completed;

[0054] 4. In order to overcome the installation error and ensure that the contact of the friction pair is surface contact, the present invention avoids point contact or line contact in the design concept; a high-precision grinding wheel can be installed on the friction testing machine, so that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com