Rope wheel stroke amplification on-board drilling machine

A technology of stroke amplification and rope pulley, which is applied in the direction of drill pipes, drill pipes, drilling equipment, etc., can solve the problems of high labor intensity of manual pneumatic drilling rigs, hidden safety hazards of manual dismantling of drill pipes, and affecting the sight of construction workers, etc. Fast troubleshooting, improved reliability and safety, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

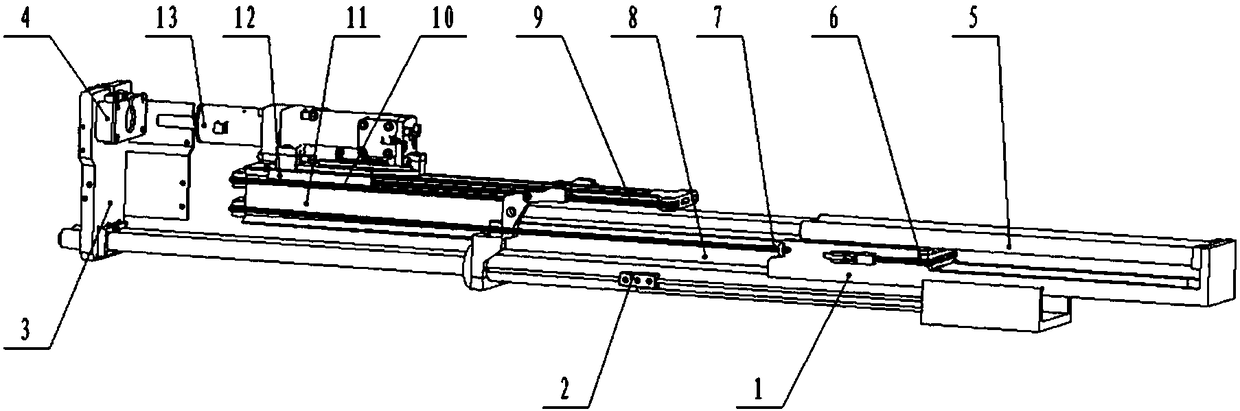

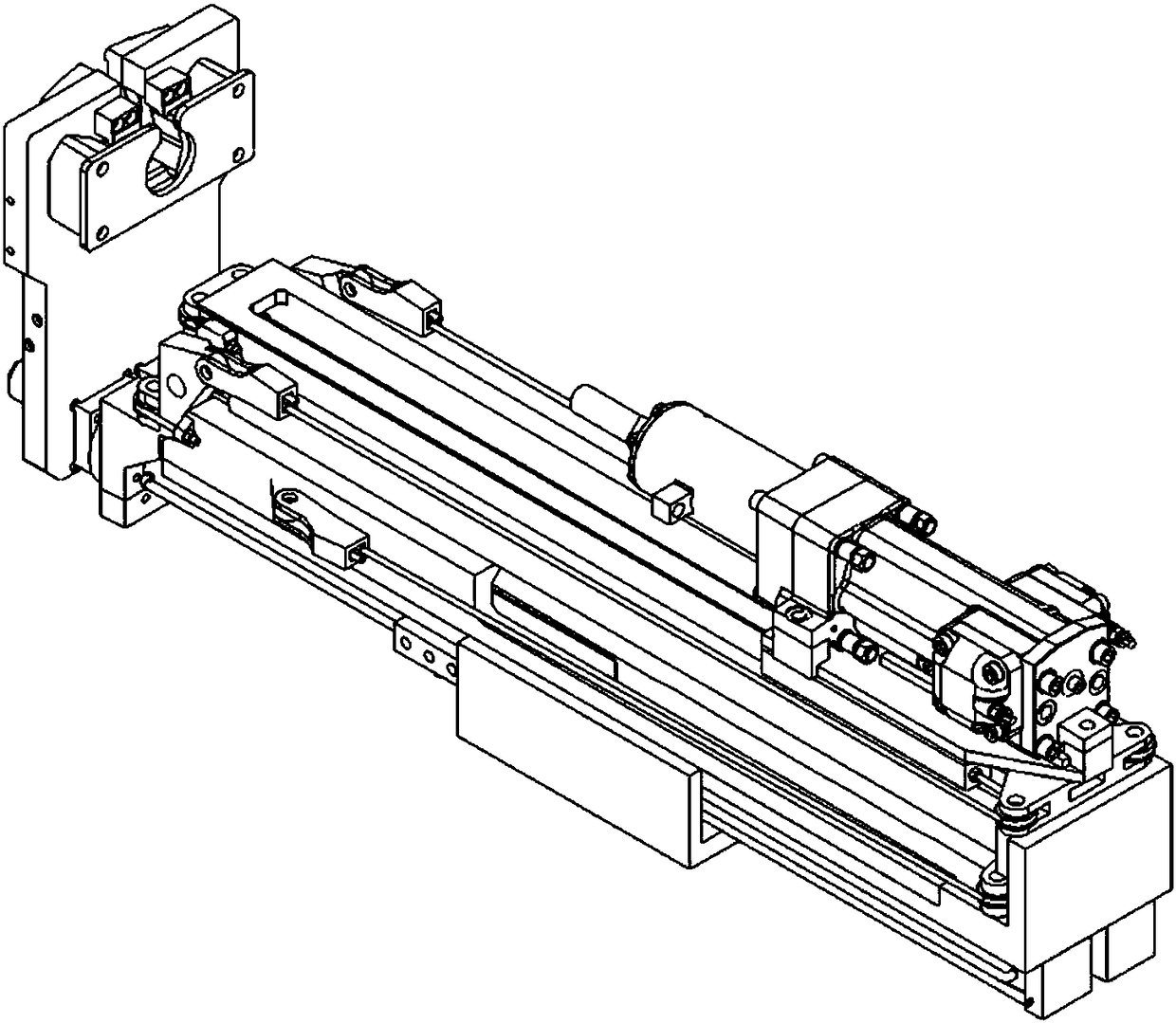

[0013] Such as figure 1 or figure 2 As shown, a rope pulley stroke amplification airborne drilling rig, which includes a slideway bottom plate 1, a positioning cylinder 2, a connecting plate 3, a clamping cylinder 4, a propulsion cylinder 5, a rope pulley assembly I6, a rope pulley assembly II7, a first-stage Slide rail 8, rope wheel assembly III9, rope wheel assembly IV10, secondary slide rail 11, sliding seat 12, impact rotary drill 13; the positioning cylinder 2 is installed on the front end of the primary slide rail 8, and the connecting plate 3 The lower end is installed on the piston rod of the positioning oil cylinder 2; the clamping oil cylinder 4 is installed on the upper end of the connecting plate 3, and the required oil that communicates with the clamping oil cylinder 4 is provided inside the connecting plate 3 and the positioning oil cylinder 2. Road; the primary slide rail 8 is installed above the slideway bottom plate 1, one end of the propulsion cylinder 5 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com