Reverse-circulation pneumatic impact down-the-hole hammer

A technology of down-the-hole hammer and reverse circulation, which is applied to the driving device for drilling, drilling equipment, earth-moving drilling and other directions in the wellbore, can solve the problems of lack of rock-breaking drilling speed, shortened tool life, reliability impact, etc. Achieve the effect of improving reliability and service life, improving purity, and increasing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

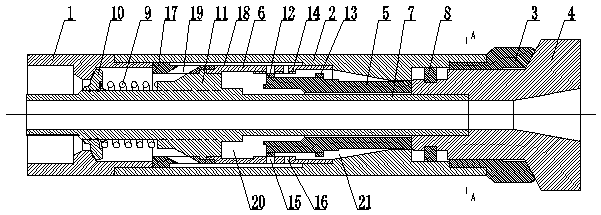

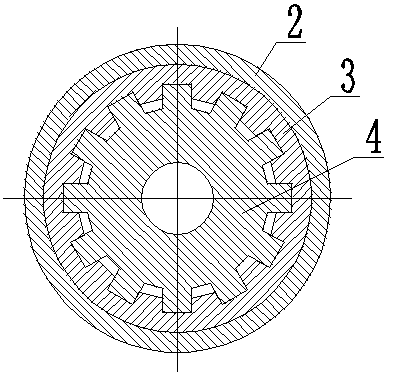

[0023] The reverse cycle pneumatic impact down-the-hole hammer is composed of an upper joint 1, a housing 2, a spline sleeve 3, a drill bit 4, a hammer 5 and a cylinder 6. One end of the housing 2 is threaded with the upper joint 1, and the other end of the housing 2 A spline sleeve 3 is mounted on one end thread, and a drill bit 4 is slidably installed in the spline sleeve 3 through a keyway; a C-shaped snap ring 8 is fixedly installed on the drill bit 4 . The purpose of the C-type snap ring 8 is to carry out intermittent contact with the end face of the spline sleeve 3 to realize axial positioning of the drill bit 4, so as to prevent the drill bit 4 from falling to the bottom of the well when pulling out the drill in the working process.

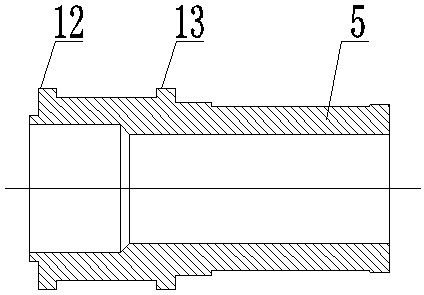

[0024] A core tube 7 is installed in the housing 2 on one side of the drill bit 4 , and the core tube 7 is a diameter-reducing body, and a diameter-reducing boss 11 is arranged on the circumference of the core tube 7 . A check valve 10 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com