Prefabricated fabricated profiled steel sheet concrete shear wall and construction method thereof

A technology of concrete shear walls and profiled steel plates, which is applied to walls, building components, buildings, etc., can solve the problems of restricting the application of prefabricated steel plate concrete shear walls, complex connection structures, high wall steel content, etc. Achieve the effects of saving manpower consumption, reducing steel content and improving applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The specific implementation of the present invention will be further described below in conjunction with the accompanying drawings.

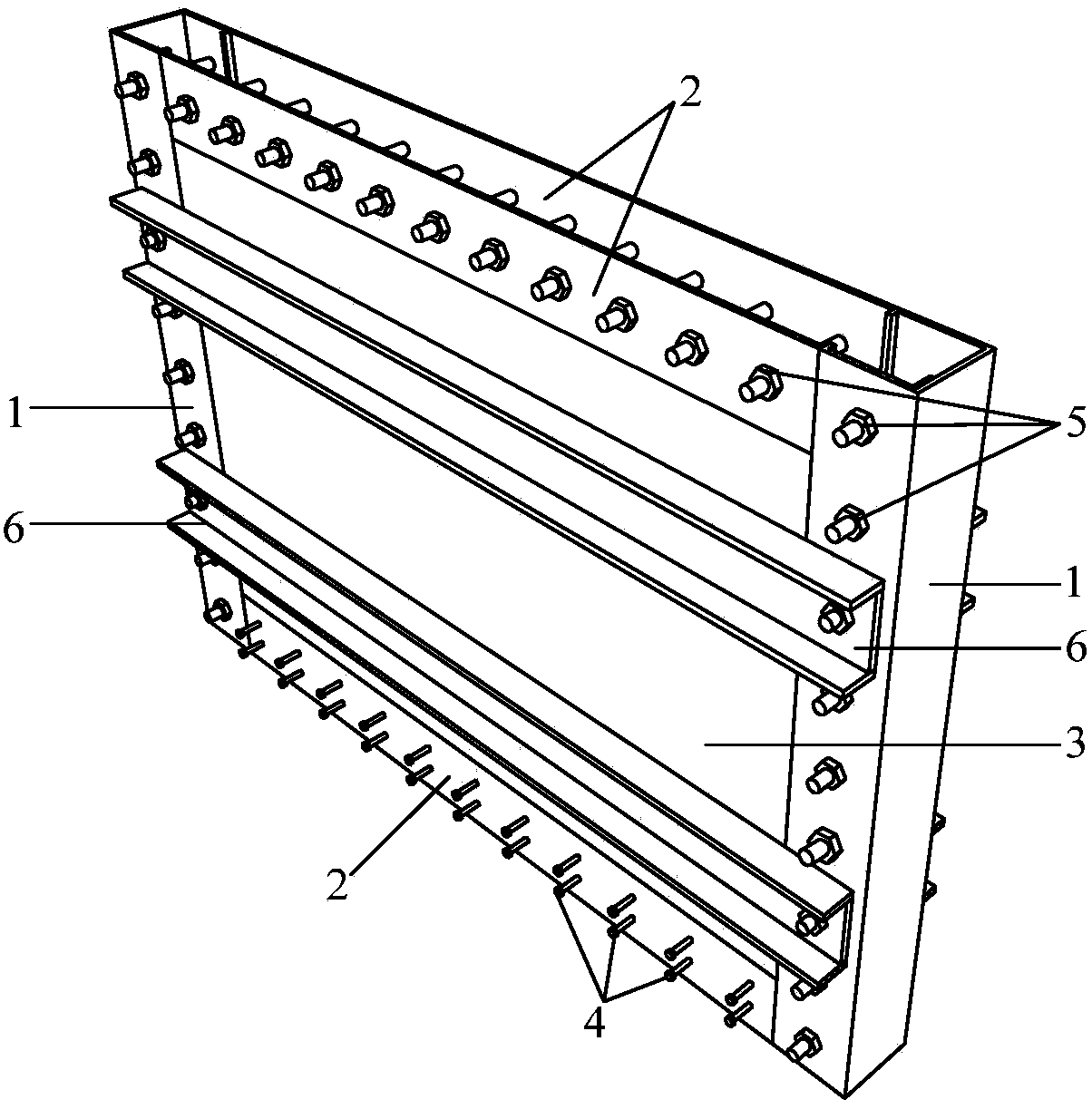

[0039] A prefabricated assembled profiled steel plate concrete shear wall structure of the present invention, the shear wall structure consists of vertical channel steel 1 at the end, horizontal steel plate 2 at the end, profiled steel plate 3, and connecting fasteners 4-6 , Adhesive coating 7, filled with concrete 8 components. The vertical channel steel 1 is arranged at the left and right ends of the shear wall, and hot-rolled or cold-formed steel can be used.

[0040] The horizontal steel plate 2 is arranged on the lower end of the shear wall, so that the lower end of the shear wall is open, which is convenient for coating adhesive and pouring concrete. If the shear wall is directly connected to the foundation, the outer surface of the lower end horizontally facing the steel plate 2 should be welded with studs 4. After the foundation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com