Transporting mechanism for long shear blade

A technology of blades and scissors, applied in the field of transfer mechanism, can solve the problems of unsafe use, edge damage, scratched hands, etc., and achieve the effect of safe handling and avoiding wear and tear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

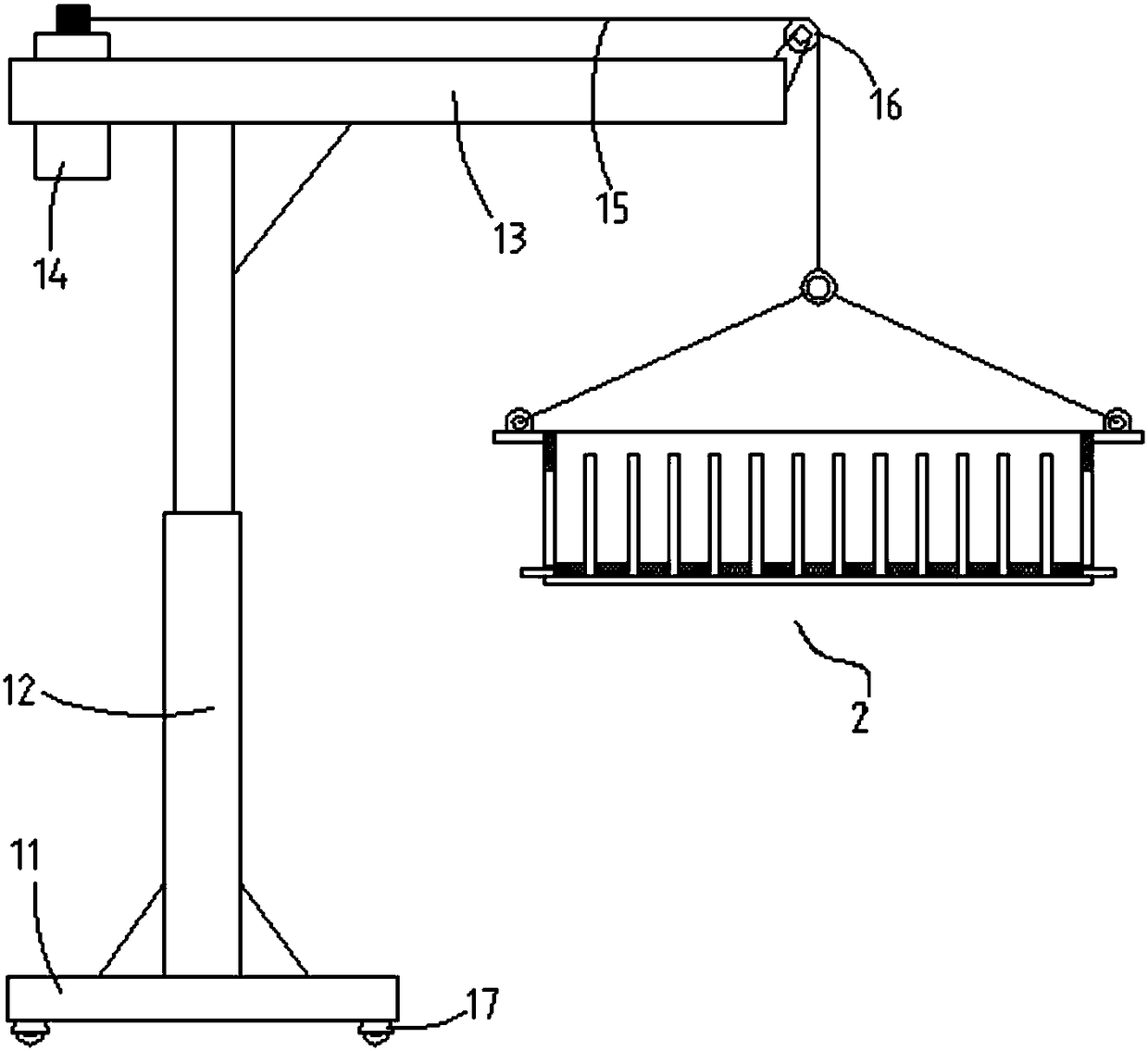

[0014] Such as Figure 1 to Figure 3 , a transfer mechanism for long blades of scissors of the present invention, comprising a base 11, a column 12, a crossbeam 13, a motor 14, a sling 15, a fixed pulley 16, a universal wheel 17 and a transfer box 2 for placing the long blades of scissors, the column 12 is fixed on the upper surface of the base 11, the universal wheel 17 is rotatably connected to the lower surface of the base 11, the crossbeam 13 is fixed on the top of the column 12, the motor 14 and the fixed pulley 16 are all arranged on the crossbeam 13, and the suspension rope 15 is set On one side of the fixed pulley 16, and one end of the suspension rope 15 is wound on the rotating shaft of the motor 14, and the other end is fixedly connected with the transfer box 2.

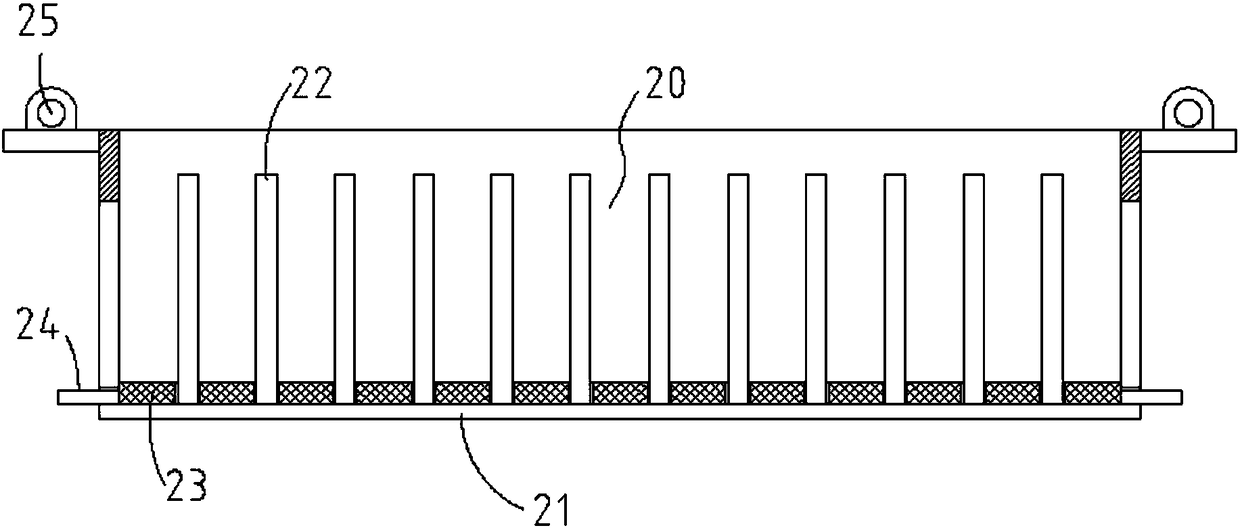

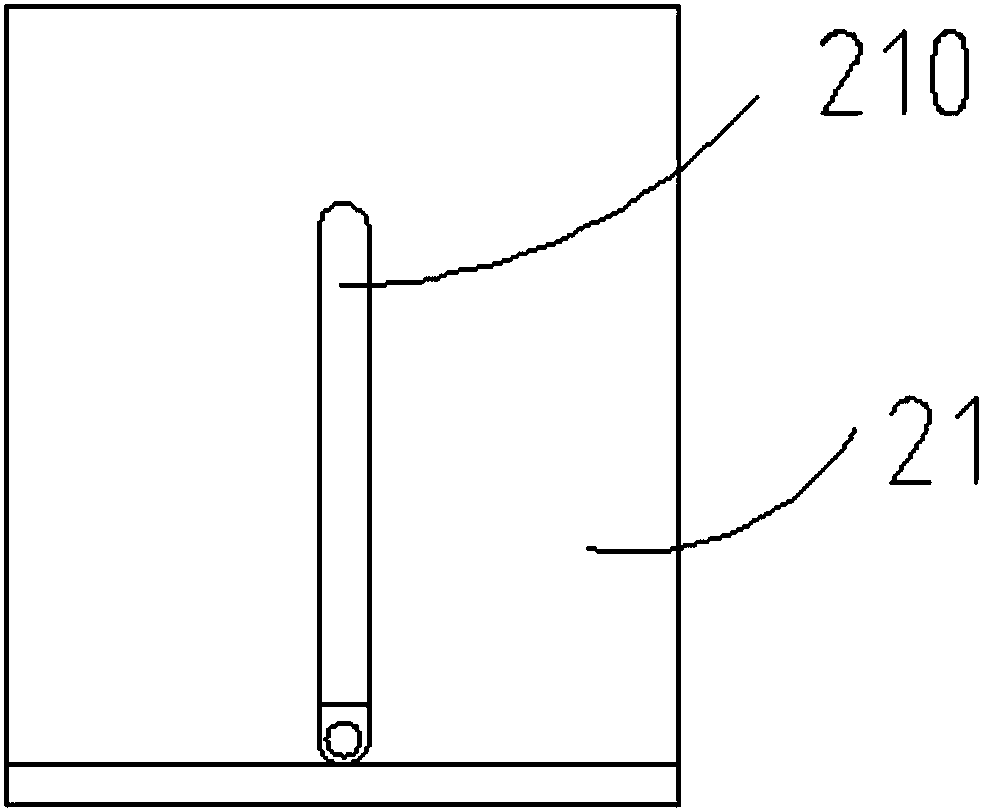

[0015] The transfer box 2 among the present invention comprises box body 21, dividing plate 22...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com