Gear and rack type glass cleaning device

A cleaning device, rack and pinion technology, applied in cleaning flexible objects, cleaning methods and utensils, cleaning methods using tools, etc., can solve the problems of high processing and manufacturing costs, short service life, poor stability, etc., and achieve easy processing and manufacturing , long service life and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

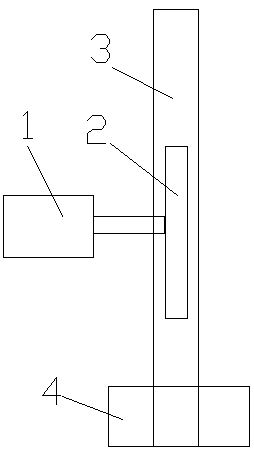

[0015] Such as figure 1 As shown, a rack-and-pinion glass cleaning device includes a wind gun 1, a gear 2, a rack 3, and a scrubbing cloth 4.

[0016] The wind gun 1 drives and connects the gear 2, the gear 2 is meshed with the rack 3, and the lower end of the rack 3 is provided with a scrubbing cloth 4.

[0017] Preferably, the cleaning device is arranged on the X-axis guide rail through a connecting plate.

[0018] Preferably, the X-axis guide rail is a dovetail groove structure, a dovetail is provided on the connecting plate, and the dovetail is arranged in the dovetail groove.

[0019] Preferably, the X-axis guide rail is I-shaped steel, a T-shaped groove is provided on the connecting plate, and the I-shaped steel is arranged in the T-shaped groove.

[0020] Preferably, the X-axis guide rail is a horizontally arranged Z-shaped steel, and the connecting plate is provided with a horizontally arranged Z-shaped groove, and the Z-shaped steel is arranged in the Z-shaped groov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com