Chaotic composite stirring system and stirring method thereof

A stirring system and a chaotic technology, which are applied to a chaotic compound stirring system and the field of stirring, can solve the problems that the tissue structure is easily damaged by shear force, the stirring speed cannot be very high, and the heat transfer effect is not obvious, so as to reduce the fluid layer. Dead zone, improved mixing efficiency, long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

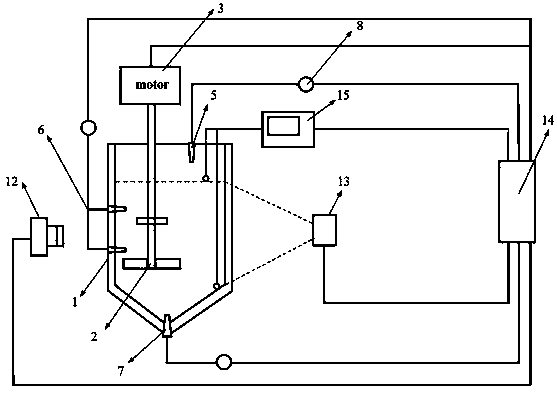

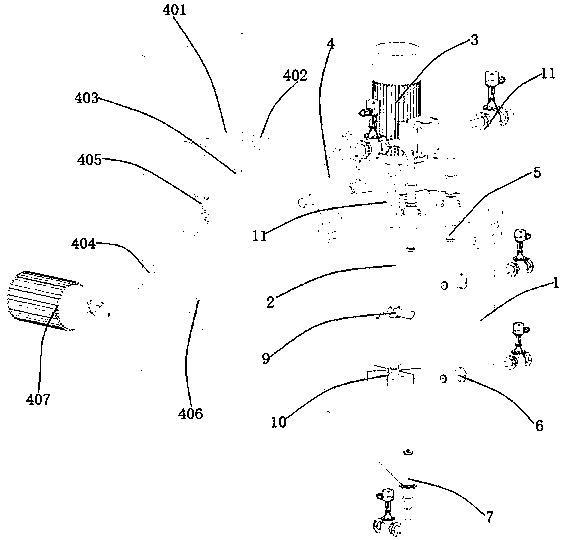

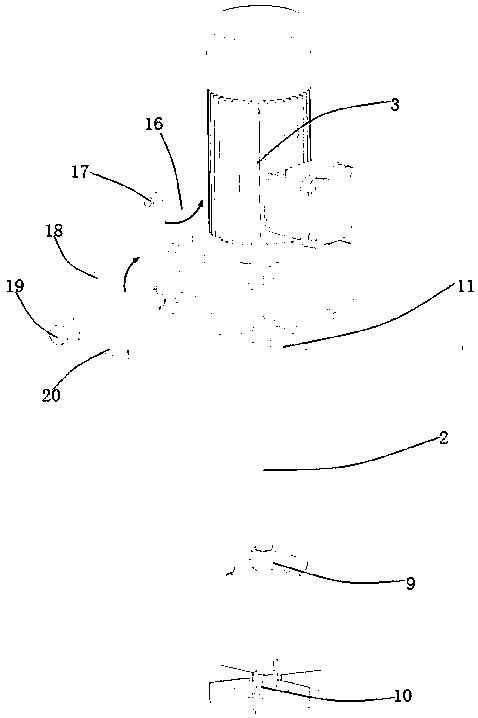

[0032] The present invention will be further described below in combination with the accompanying drawings and specific embodiments.

[0033] Such as Figure 1~3 As shown, a chaotic composite stirring system includes a chaotic composite stirring device and a monitoring and control system. The chaotic composite stirring device includes a stirring tank 1, a stirring component 2, a driving device 3, a transmission device 4, a top blowing swirl spray gun 5, a side blowing Swirling spray gun 6, bottom blowing swirl spray gun 7, air intake pipe I, air intake pipe II, air intake pipe III, transmission device 4 includes a driving member and a transmission member, the driving member is arranged on one side of the stirring tank 1, and the transmission member is fixedly arranged on the stirring tank 1 side. The top of the tank 1, the output end of the driving member is connected with the transmission member, the driving device 3 is fixedly arranged on the top of the transmission member, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com