Method for reloading and simulating various industrial Internet of Things sensor equipment

A technology of sensor equipment and industrial Internet of Things, applied in the field of Internet of Things, can solve the problems of unfavorable debugging, difficult maintenance, high cost, etc., and achieve the effect of avoiding repeated debugging, reducing the use area, and reducing investment costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

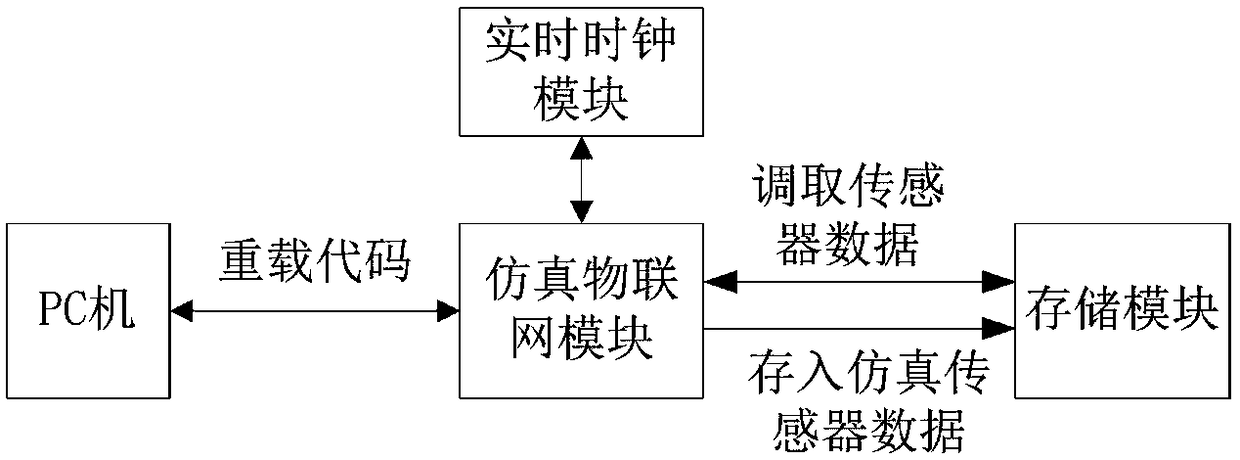

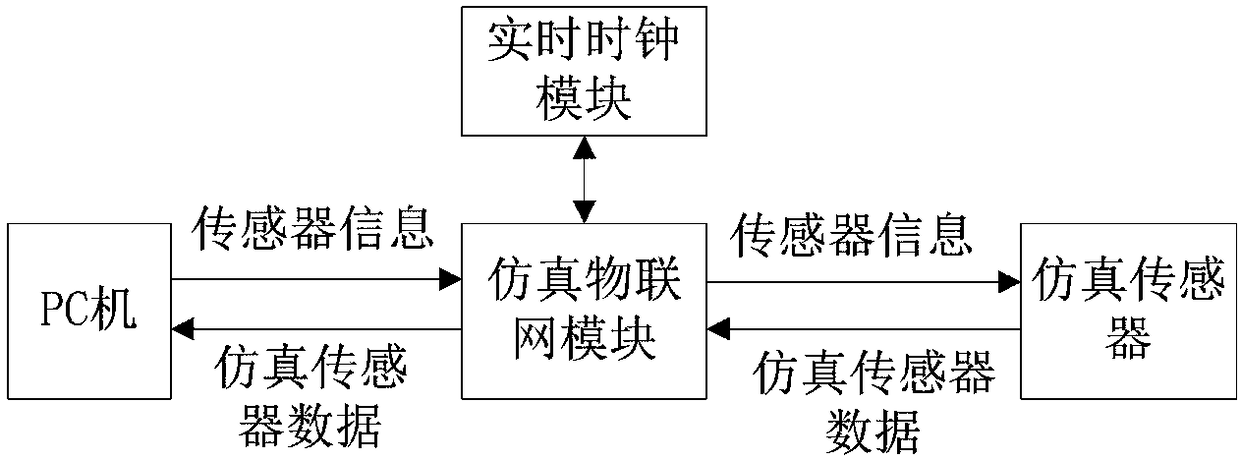

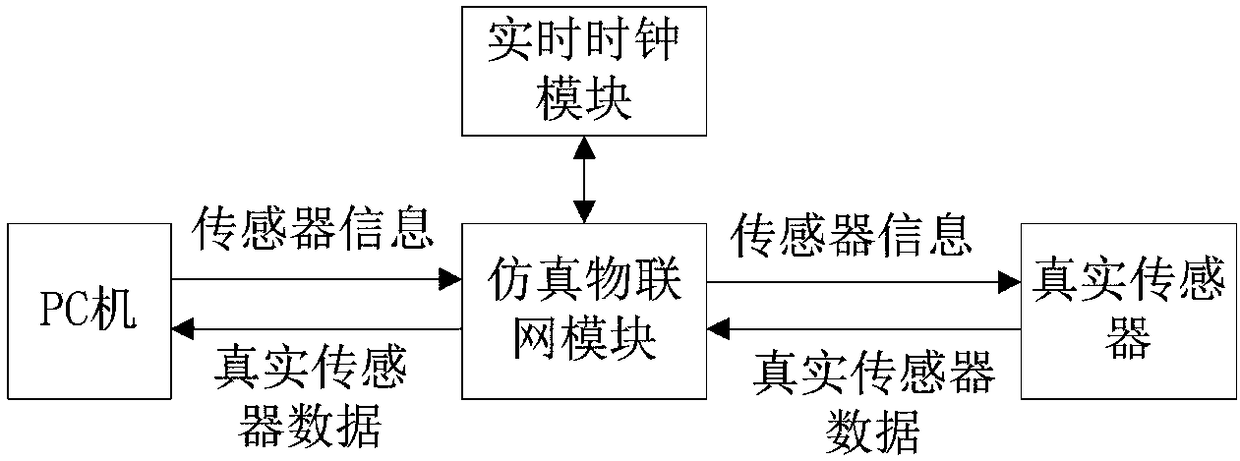

[0036] Such as figure 1 with image 3 As shown, a method for overloading and simulating a variety of industrial IoT sensor devices, including a program control system, a simulated IoT module, a real-time clock module, a communication module, and a storage module; the program control system communicates with the simulated IoT through the communication module Module communication, the simulated IoT module is connected to the storage module and the real-time clock module; the display screen is used to display the type of the current simulated sensor, the real-time clock module, the total number of preset data sequences, the simulation start time, the current output data serial number, and the current output data value .

[0037] The program control system is used to send overloaded codes and preset data sequences; here, a PC is selected as the program control system, and the control method includes the following steps:

[0038] Step 10, reload stage: PC sends the corresponding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com