Coal mining output calculation method

A calculation method and the technology of coal mining machines, which are applied to measuring devices, mining equipment, earthwork drilling and mining, etc., can solve problems such as lag, and achieve the effect of overcoming lag and submitting calculation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

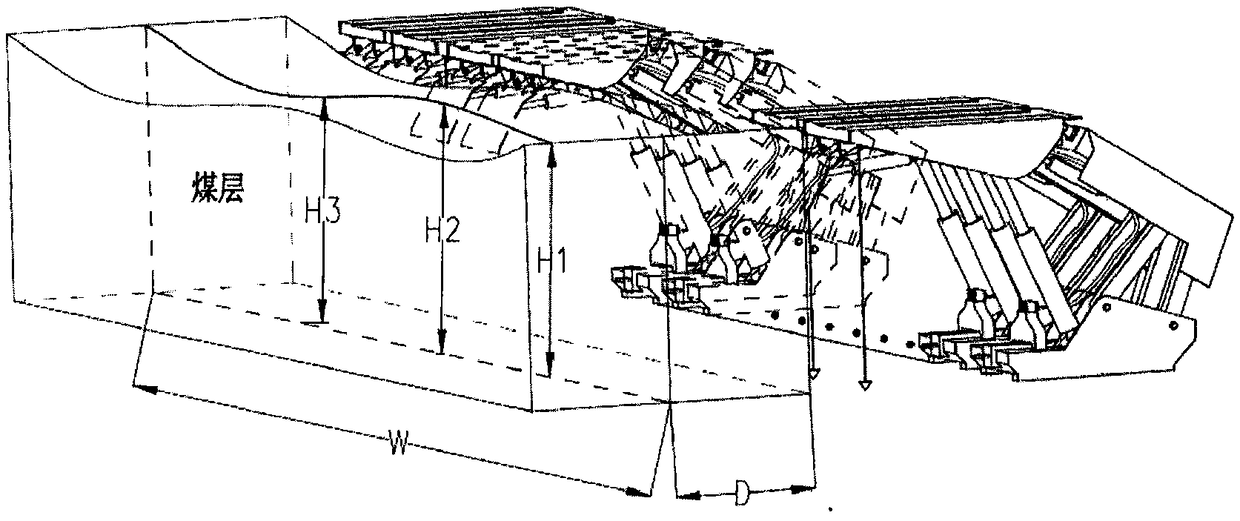

[0030] The present invention proposes a calculation method for a fully-mechanized mining face, the basic principle of which is: by calculating the volume V of each cutter on the fully-mechanized mining face, the average density ρ of the coal seam cut by the fully-mechanized mining face is Relatively fixed and easy to measure, multiply the coal seam density by the volume to get the coal mining volume p per knife, and sum the coal mining volume p per knife to get the total coal mining volume P.

[0031] The volume V of each cutter on the fully mechanized mining face is the bottom area S of each cutter multiplied by the height H′. In the coal seam, each cutter is driven by the hydraulic support, so each cutter cuts The bottom surface of the coal seam is approximately rectangular, and the width W of the fully mechanized mining face is fixed, and the depth D cut by each knife is a set value, so the D cut by each knife is also fixed.

[0032] The height of the coal seam may vary on ...

Embodiment 2

[0039] In another embodiment, considering that the degree of undulation of the coal mine measurement is different, in order to calculate the workload more accurately, the volume of coal mined per knife is calculated in a differentiated and segmented manner. Firstly, the height measuring sensor is used to measure the height corresponding to the coal seam to be mined, and the number of hydraulic supports installed on the above height measuring sensor is relatively large compared to the interval supports. Then, select the hydraulic support installed with the height measuring sensor corresponding to the large difference in the above data, indicating that the coal seam height has undergone a large change between the two hydraulic supports, and open the other installations between the above two hydraulic supports. The altimeter sensor is used for measurement and calculation. That is to say, when calculating the volume of the cut coal seam, it is first divided into several sections w...

Embodiment 3

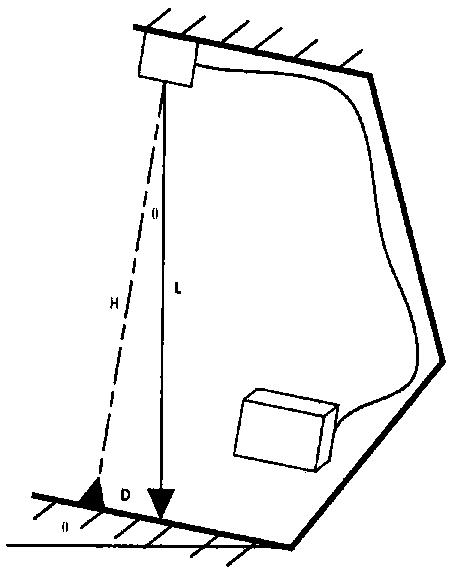

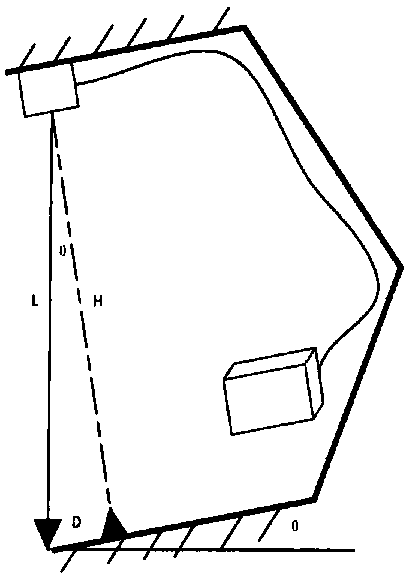

[0052] Accompanying drawing 2 schematically shows a certain problem faced in the height measurement of the current hydraulic support: that is, when the working face of the fully mechanized mining face must adopt the down mining and upward mining technology due to the undulation of the coal seam, the angle of the support often has a large deviation. Laser ranging method and other methods, such as gravity measurement method, hydraulic measurement method, inclination measurement method, etc., measure the distance between the hydraulic support and the vertical plane, that is, the vertical height L, or other methods measured by some height measurement methods. The height is between the vertical height L and the actual height H from the base of the hydraulic support, and there is a deviation from the vertical distance between the hydraulic support and the base. When estimating the coal mining volume or other calculations based on the coal mining height, use The parameter of should be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com