Three-way vibration-isolation floor slab structure

A floor and vibration isolation technology, which is applied to floors, building components, building structures, etc., can solve the problems of high cost and complicated design methods, and achieve the goal of eliminating construction costs, speeding up construction progress, and facilitating local three-way vibration isolation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

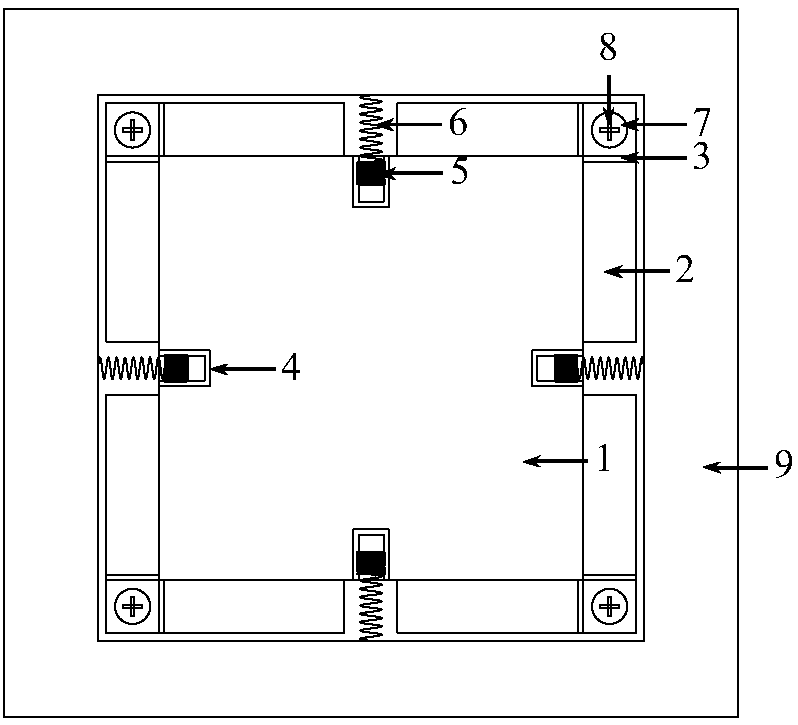

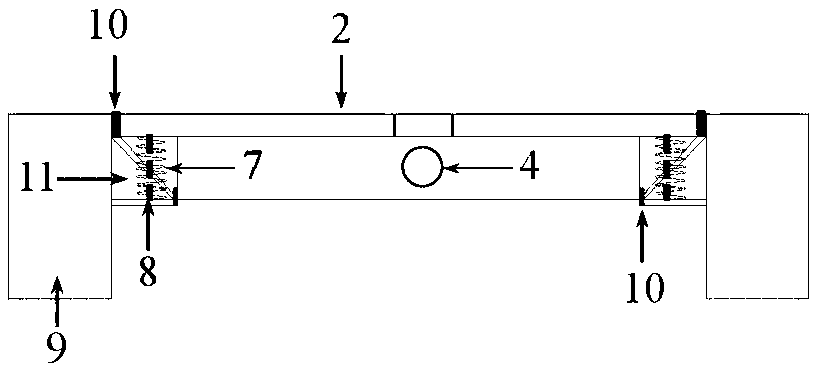

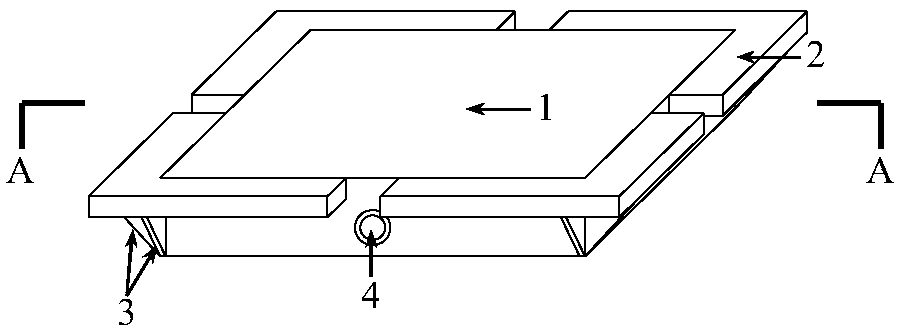

[0024] Figure 1~ image 3 As shown, a three-way vibration isolation floor structure includes prefabricated concrete slab 1, peripheral angle steel 2, peripheral angle steel stiffener 3, embedded sleeve 4, horizontal spring joint 5, horizontal spring 6, vertical spring 7, and chain 8 , concrete beam 9, flexible waterproof material 10, support angle steel 11, peripheral angle steel hook 12, support angle steel hook 13, embedded bolt 14, support angle steel stiffener 15.

[0025] exist Figure 1a and image 3 In the construction, the concrete beam 9 is poured in advance, and then the supporting angle steel 11 is fixed on the beam through the embedded bolt 14 . The positions of the pre-embedded bolts 14 make the bottom surface of the precast concrete slab 1 equal to the bottom surface of the supporting angle steel 11 under the design load. The q...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gap width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com