Cyclic cooling method and device for twisting thick galvanized steel wire rope strands

A technology of circulating cooling and wire rope strands, which is applied to auxiliary devices for rope making, textiles and papermaking, textile cables, etc. The effect of peeling off the zinc layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0019] The circulating cooling method and device of the twisted thick galvanized steel wire rope strands of the present invention are described in further detail:

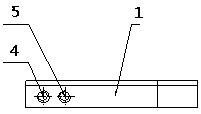

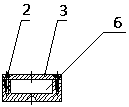

[0020] The circulating cooling device for twisting thick galvanized steel wire strands of the present invention presses figure 1 , It is composed of a tile body 1, an M4×10 hexagon socket head screw 2, a gland 3, an oil inlet 4, an oil outlet 5, and a slot 6; a gland 3 is provided on the tile body 1, using M4×10 The hexagon socket head screw 2 is fastened and connected, the shoe body 1 is provided with a slot 6 inside, and an oil inlet 4 and an oil outlet 5 are provided on the side.

[0021] The material of the circulating cooling device for twisting thick galvanized steel wire strands is Cr12 cemented carbide, the Rockwell hardness HR is greater than or equal to 60, and the smoothness of the contact surface with the steel wire is not greater than 1.6.

[0022] The circulating cooling device for twisting thick galvanized ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com