Water spraying loom battening shaft waterproof ring

A technology of water-jet looms and waterproof rings, which is applied in looms, textiles, textiles and papermaking, etc., can solve the problems of reducing the waterproof effect, reducing the service life of the beating shaft, and reducing the weaving efficiency of water-jet looms, so as to improve Maintenance and replacement efficiency, and the effect of improving the waterproof effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to better understand the present invention, the implementation manner of the present invention will be explained in detail below in conjunction with the accompanying drawings.

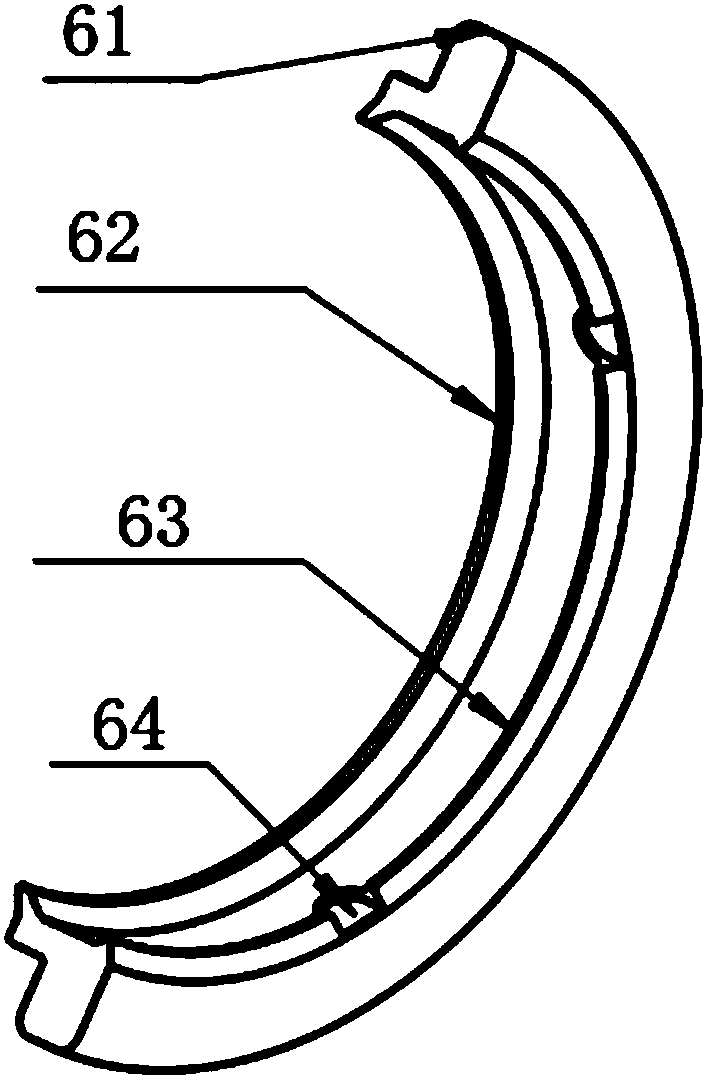

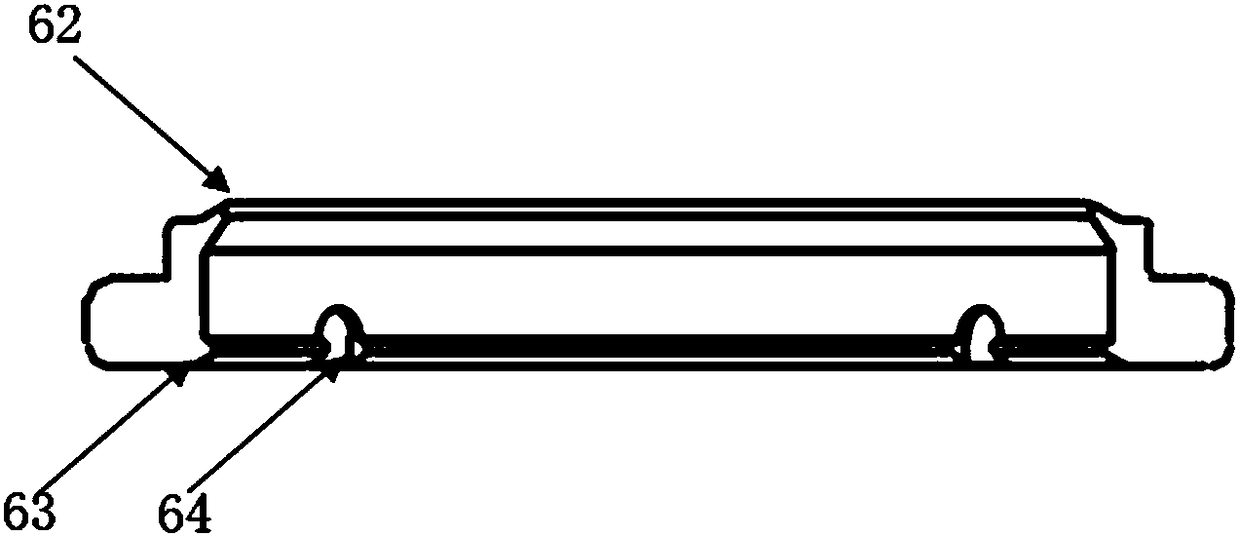

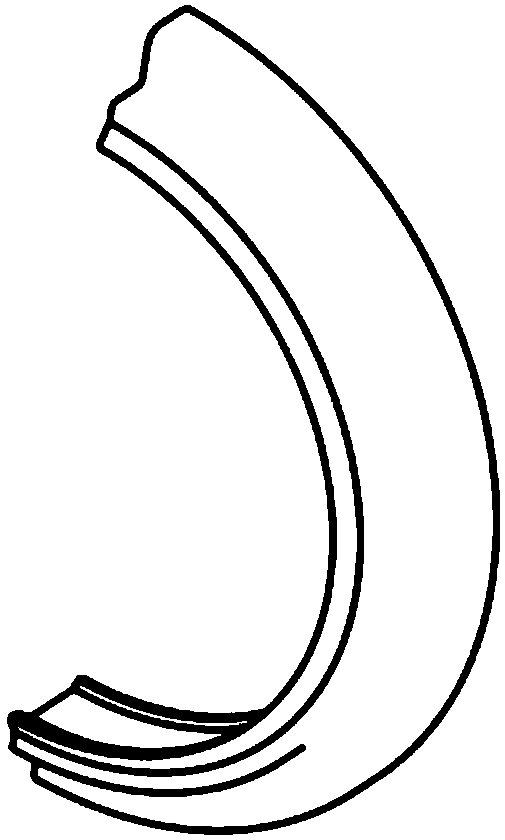

[0020] Such as figure 1 As for Figure 5 As shown, a water-jet loom beat-up shaft waterproof ring, the components involved include: a beat-up shaft 1, a bearing pad seat support 2, a bearing pad seat fixing screw 3, a bearing pad seat 4, a bearing pad 5, a waterproof ring 6, and a bearing pad Seat connection screw 7, the bearing pad support 1 is fixed on the frame through screw connection, the bearing pad seat 4 is connected to the bearing pad seat support 1 through the bearing pad seat fixing screw 3, and is kept fixed with it after adjusting the position, the bearing pad 5 is installed on the bearing bush seat 4 and kept fixed with it. The beat-up shaft 1 passes through the space in the middle of the bearing bush 5, keeps coaxial with it, and swings along the axis within a certain an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com