Desulfurizing agent prepared by taking waste limestone powder as raw material and preparation method thereof

A technology of limestone powder and desulfurization agent, which is applied in the direction of fuel additives, fuel, petroleum industry, etc., can solve the problems of environmental pollution, loss of natural resources, poor desulfurization effect of desulfurization agent, etc., and achieve the effect of reducing environmental pollution and realizing comprehensive utilization of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] A kind of desulfurizing agent preparation method prepared from waste limestone powder in the present invention, comprises the following steps:

[0024] Step 1) Collect waste limestone powder: Recycle the limestone powder produced by vibrating screening of machine-made sand and gravel, the limestone powder obtained by negative pressure vacuuming or electrostatic vacuuming, and the dust and leakage produced during the process of machine-made sand and gravel processing to obtain waste limestone powder;

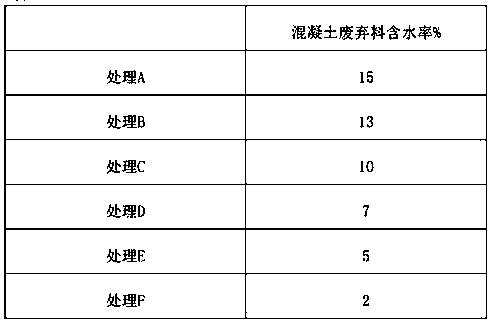

[0025] Step 2) Collect concrete waste: filter the waste slurry produced by the concrete mixing plant or settle naturally to obtain concrete waste slag, stack the concrete waste slag naturally, dry until the moisture content is ≤ 10%, and crush it to obtain concrete waste;

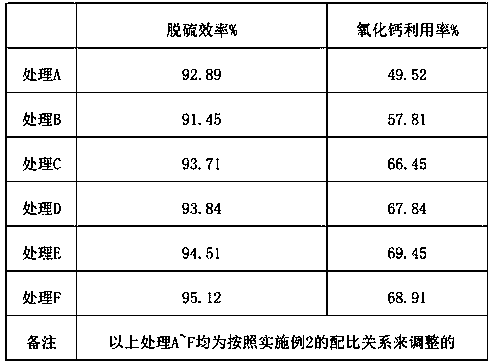

[0026] Step 3) mixing waste materials: take 14-19 parts by weight of the waste limestone powder collected in step 1), take 0-2 parts by weight of the concrete waste collected in step 2), and mix the ab...

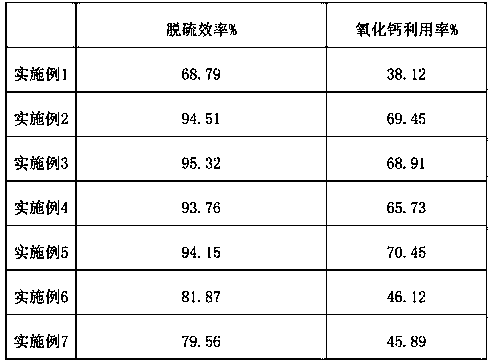

Embodiment 1

[0035] The raw material composition of the desulfurizer is 14kg of waste limestone powder by weight.

Embodiment 2

[0037] The raw material components of the desulfurizer are 19kg of waste limestone powder, 2kg of concrete waste, and 4kg of coal gangue by weight; the calcium carbonate content in the coal gangue is 90%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com