Self-deposition coating based on acrylic acid/epoxy resin as main material and preparation method and application thereof

An acrylic resin and epoxy resin technology, applied in the field of metal surface treatment and metal coating, can solve the problems of low flexibility of epoxy resin, general adhesion performance, increase operation process, etc., to reduce the burden of sewage treatment, product The effect of low cost and simple construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

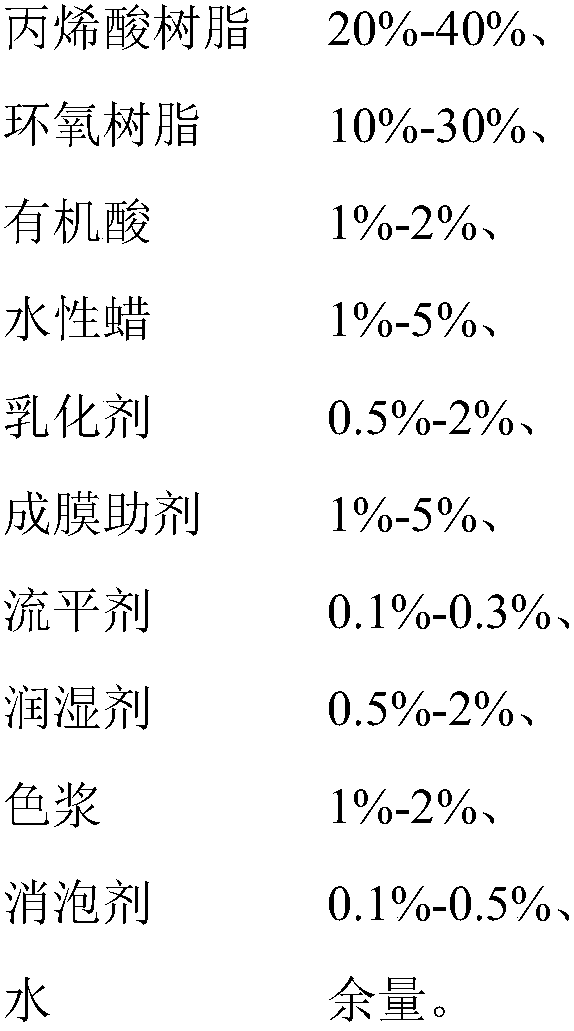

[0037] (1) Self-deposition coatings are composed of the following substances in terms of mass percentages:

[0038]

[0039] The pH of the autodeposition coating is 2.5.

[0040] (2) Preparation method: first take about 80% deionized water, add isomeric tridecyl alcohol polyoxyethylene ether into the water under medium and low speed stirring at 200r / min, after stirring evenly, add dodecyl alcohol with medium speed stirring at 500r / min Ester, leveling agent, wetting agent and defoamer, after stirring evenly, add acrylic resin, epoxy resin, water-based wax and color paste with medium-high speed stirring at 1000r / min, stir evenly, add citric acid to adjust the pH to 2.5, and finally Add the remaining deionized water, stir evenly, discharge and filter to remove larger particles.

Embodiment 2

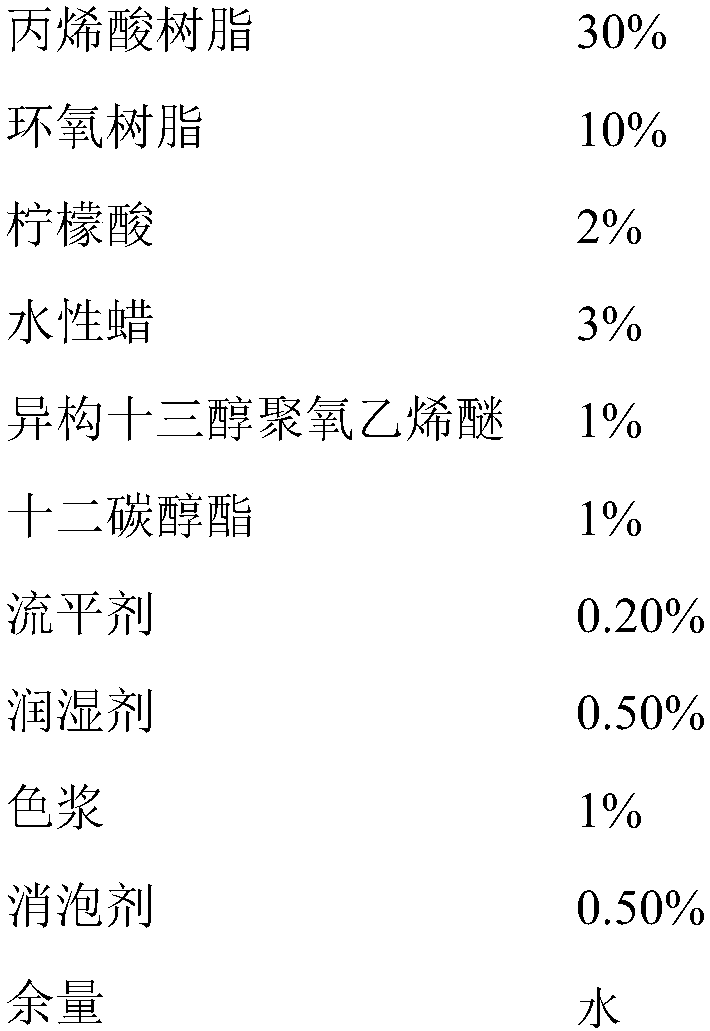

[0042] (1) Self-deposition coatings are composed of the following substances in terms of mass percentages:

[0043]

[0044]

[0045] The pH of the autodeposition coating is 2.5.

[0046] (2) Preparation method: first take about 80% deionized water, add isomeric tridecyl alcohol polyoxyethylene ether into the water under medium and low speed stirring at 200r / min, after stirring evenly, add dodecyl alcohol with medium speed stirring at 500r / min Ester, leveling agent, wetting agent and defoamer, after stirring evenly, add acrylic resin, epoxy resin, water-based wax and color paste with medium-high speed stirring at 1000r / min, stir evenly, add citric acid to adjust the pH to 2.5, and finally Add the remaining deionized water, stir evenly, discharge and filter to remove larger particles.

Embodiment 3

[0048] (1) Self-deposition coatings are composed of the following substances in terms of mass percentages:

[0049]

[0050] The pH of the autodeposition coating is 2.8.

[0051] (2) Preparation method: first take about 80% deionized water, add isomeric tridecyl alcohol polyoxyethylene ether into the water under medium and low speed stirring at 200r / min, after stirring evenly, add dodecyl alcohol with medium speed stirring at 500r / min Ester, leveling agent, wetting agent and defoamer, after stirring evenly, add acrylic resin, epoxy resin, water-based wax and color paste with medium-high speed stirring at 1000r / min, stir evenly, add maleic acid to adjust the pH to 2.8. Finally, add the remaining deionized water, stir evenly, discharge and filter to remove larger particles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Luster | aaaaa | aaaaa |

| Gloss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com