Material for sanitary hardware and preparation method thereof

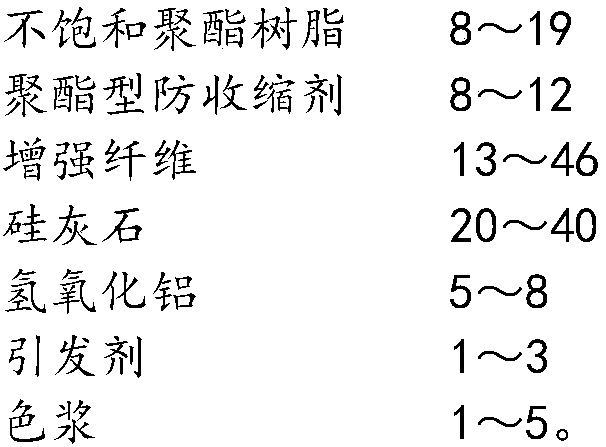

A technology for hardware and sanitary ware, applied in the field of hardware, can solve the problem of not being able to adapt to the high requirements of elongation at break and flexural modulus, and achieve the goal of improving resistance to deformation and damage, saving costs, and improving elongation at break and flexural modulus. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

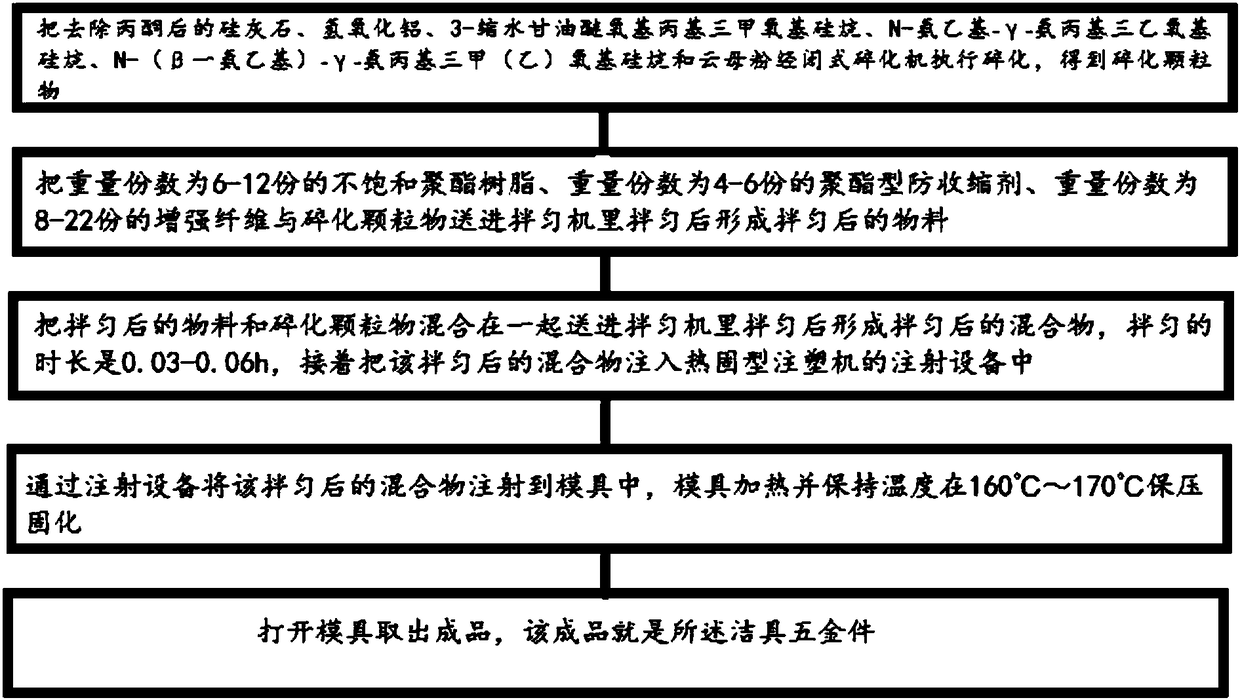

Method used

Image

Examples

Embodiment 1

[0037] The material of the sanitary ware hardware, the material of the sanitary ware hardware includes: 6 parts by weight of unsaturated polyester resin, 4 parts by weight of polyester type anti-shrinkage agent, 8 parts by weight of reinforced Fiber, parts by weight are 10 parts of mica powder, parts by weight of 3-glycidyl etheroxypropyl trimethoxysilane, parts by weight of N-aminoethyl-γ-aminopropyl 0.08 parts Triethoxysilane, 0.02 parts by weight of N-(β-aminoethyl)-γ-aminopropyl trimethyl (ethyl)oxysilane, 12 parts by weight of wollastonite and parts by weight 4 parts of aluminum hydroxide.

[0038] The unsaturated polyester resin is prepared by diluting unsaturated resin with styrene, wherein the weight ratio of styrene and unsaturated resin satisfies:

[0039] Styrene 60

[0040] unsaturated resin 40.

[0041] The unsaturated resin is o-phthalic unsaturated polyester resin or iso-phthalic unsaturated polyester resin.

[0042] The polyester type anti-shrinkage agent i...

Embodiment 2

[0058] The material of sanitary ware hardware, the material of described sanitary ware hardware comprises: the unsaturated polyester resin that is 9 parts by weight, the polyester type anti-shrinkage agent that is 5 parts by weight, the reinforcement that is 15 parts by weight Fiber, parts by weight are 13 parts of mica powder, parts by weight of 3-glycidyl etheroxypropyl trimethoxysilane, parts by weight of N-aminoethyl-γ-aminopropyl 0.16 parts Triethoxysilane, 0.09 parts by weight of N-(β-aminoethyl)-γ-aminopropyl trimethyl (ethyl)oxysilane, 18 parts by weight of wollastonite and parts by weight 5 parts of aluminum hydroxide.

[0059] The unsaturated polyester resin is prepared by diluting unsaturated resin with styrene, wherein the weight ratio of styrene and unsaturated resin satisfies:

[0060] Styrene 67.5

[0061] Unsaturated resins 37.5.

[0062] The unsaturated resin is o-phthalic unsaturated polyester resin or iso-phthalic unsaturated polyester resin.

[0063] Th...

Embodiment 3

[0079] The material of the sanitary ware hardware, the material of the sanitary ware hardware includes: 12 parts by weight of unsaturated polyester resin, 6 parts by weight of polyester type anti-shrinkage agent, 22 parts by weight of reinforced Fiber, parts by weight are 16 parts of mica powder, parts by weight of 3-glycidyl ether oxypropyl trimethoxysilane, parts by weight of N-aminoethyl-γ-aminopropyl 0.24 parts Triethoxysilane, 0.16 parts by weight of N-(β-aminoethyl)-γ-aminopropyl trimethyl (ethyl)oxysilane, 24 parts by weight of wollastonite and parts by weight It is 6 parts of aluminum hydroxide.

[0080] The unsaturated polyester resin is prepared by diluting unsaturated resin with styrene, wherein the weight ratio of styrene and unsaturated resin satisfies:

[0081] Styrene 65

[0082] unsaturated resin 40.

[0083] The unsaturated resin is o-phthalic unsaturated polyester resin or iso-phthalic unsaturated polyester resin.

[0084] The polyester type anti-shrinkag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural modulus | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com