Apparatus for producing corrugated texture decorations and corrugated tiles thereof

A corrugation and texture technology, applied in ceramic molding machines, manufacturing tools, etc., can solve the problems of lack of variability, single corrugated texture decoration, complex process, etc., and achieve the effects of random and diverse corrugated textures, various adjustment methods, and simple process control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

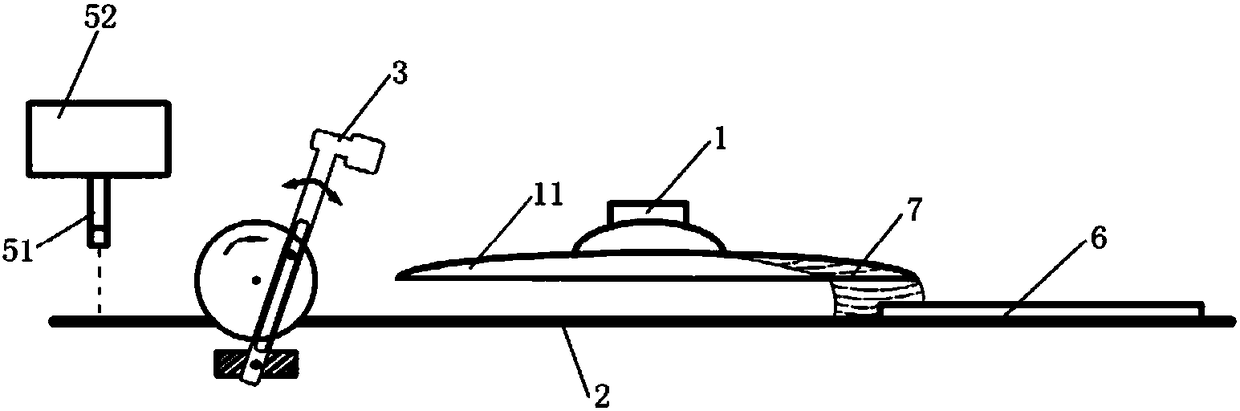

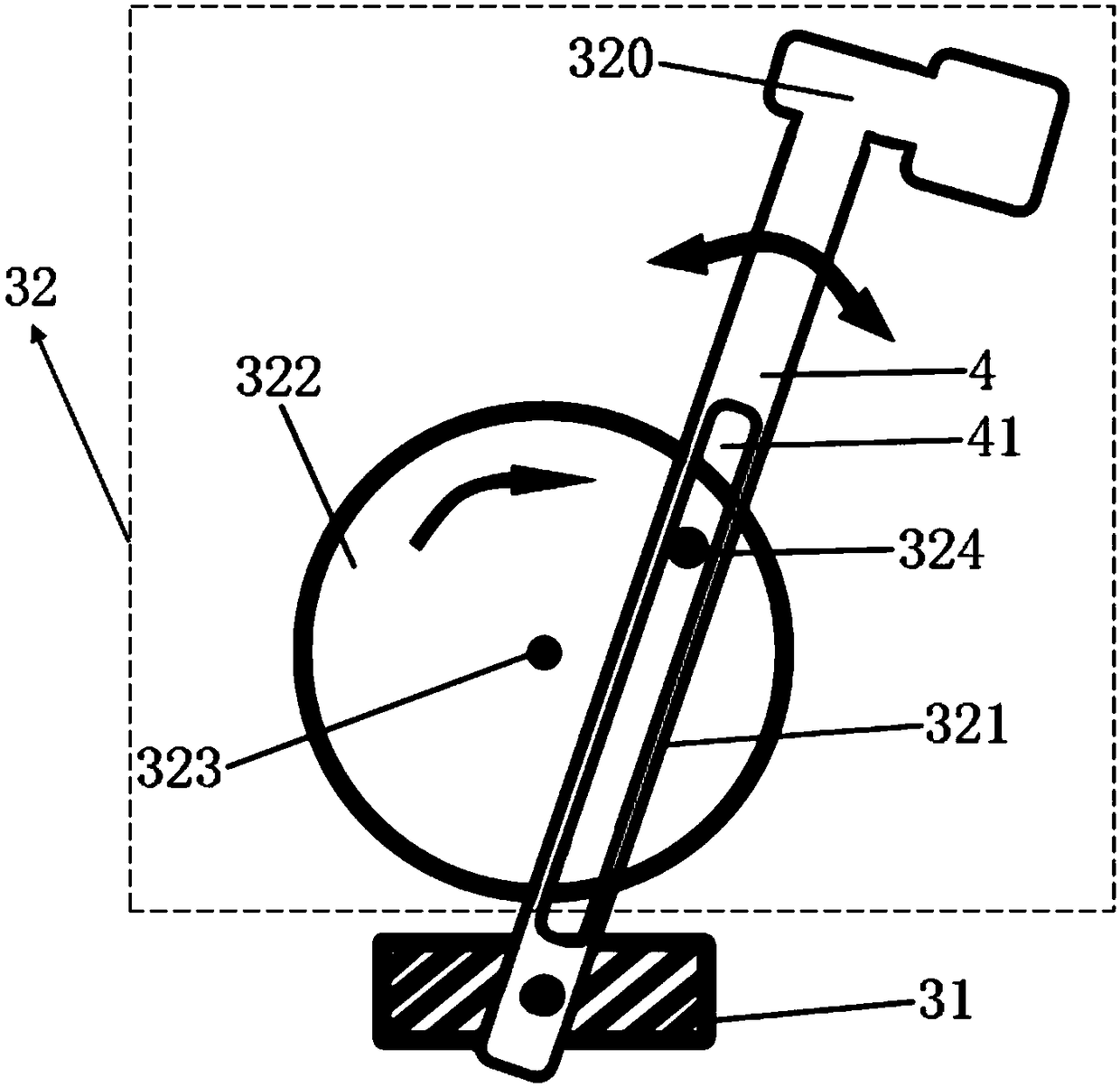

[0023] Such as figure 1 As shown, a device for producing corrugated texture decoration includes a bell jar glazer 1, a glaze conveyor belt 2 and a corrugation generator 3; the bell jar glazer 1 is installed on the glaze conveyor belt 2 above; the corrugation generator 3 is installed on the side of the non-glazed curtain of the bell jar glazing device 1; the corrugation generator 3 includes a fixed base 31, a knocking device 32 and a driving motor; the knocking The bottom of the device 32 is installed on the fixed base 31; the driving motor drives the knocking end 320 of the knocking device 32 to make a knocking movement on the glaze bell jar of the bell jar glazer 1 .

[0024] The present invention proposes a device for producing corrugated texture decoration, which is mainly installed on the non-g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com