Machine vision based ultrasonic object cutting device and cutting method thereof

A technology of machine vision and cutting equipment, which is applied in metal processing and other directions, can solve the problems of increased cutting failure rate, unsuitable for large-scale production, and low cutting precision, so as to improve flexibility and controllability, realize large-scale production, The effect of improving cutting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0062] In this embodiment, the items cut by the equipment will be described below by taking sandwich food as an example.

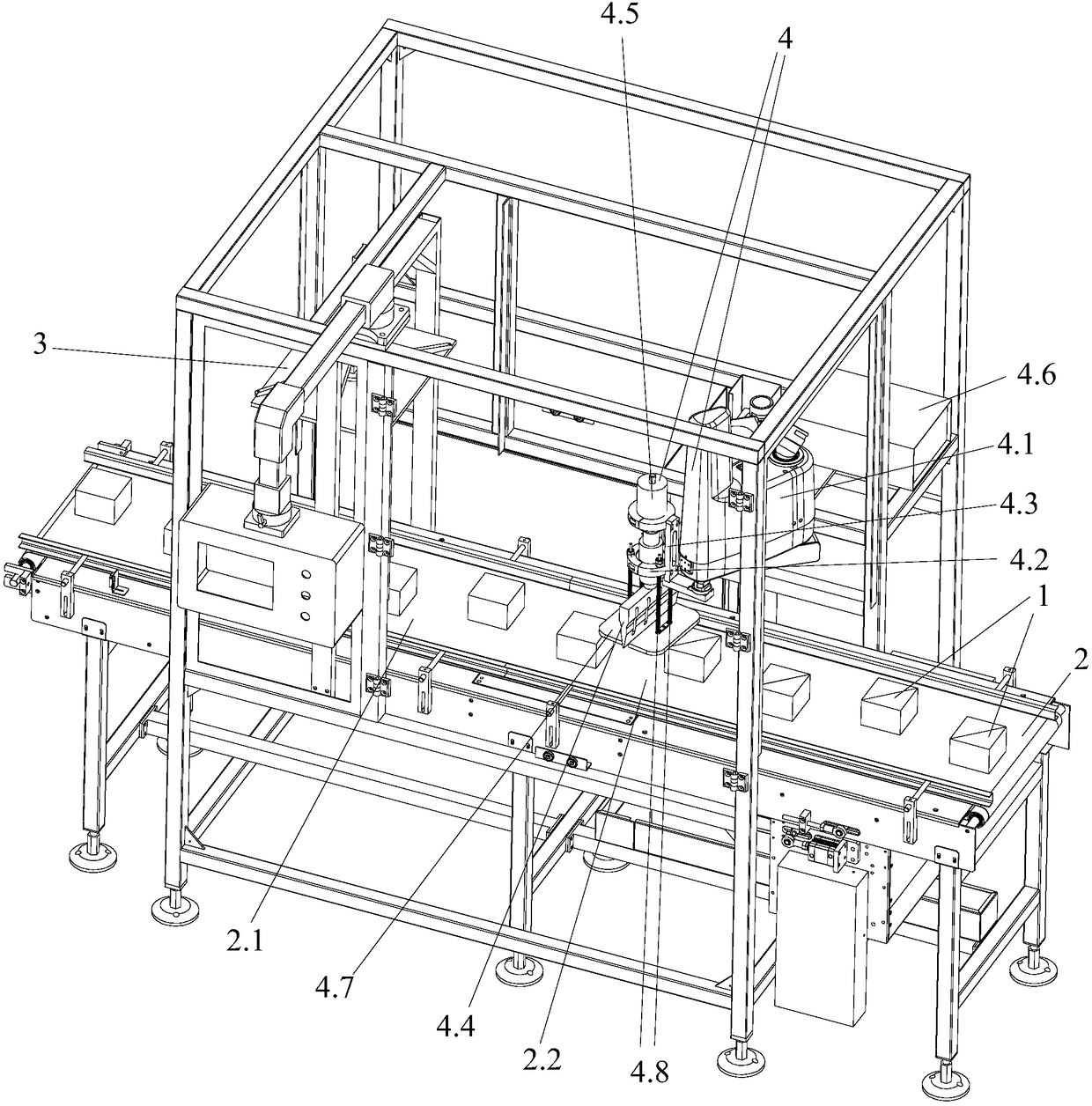

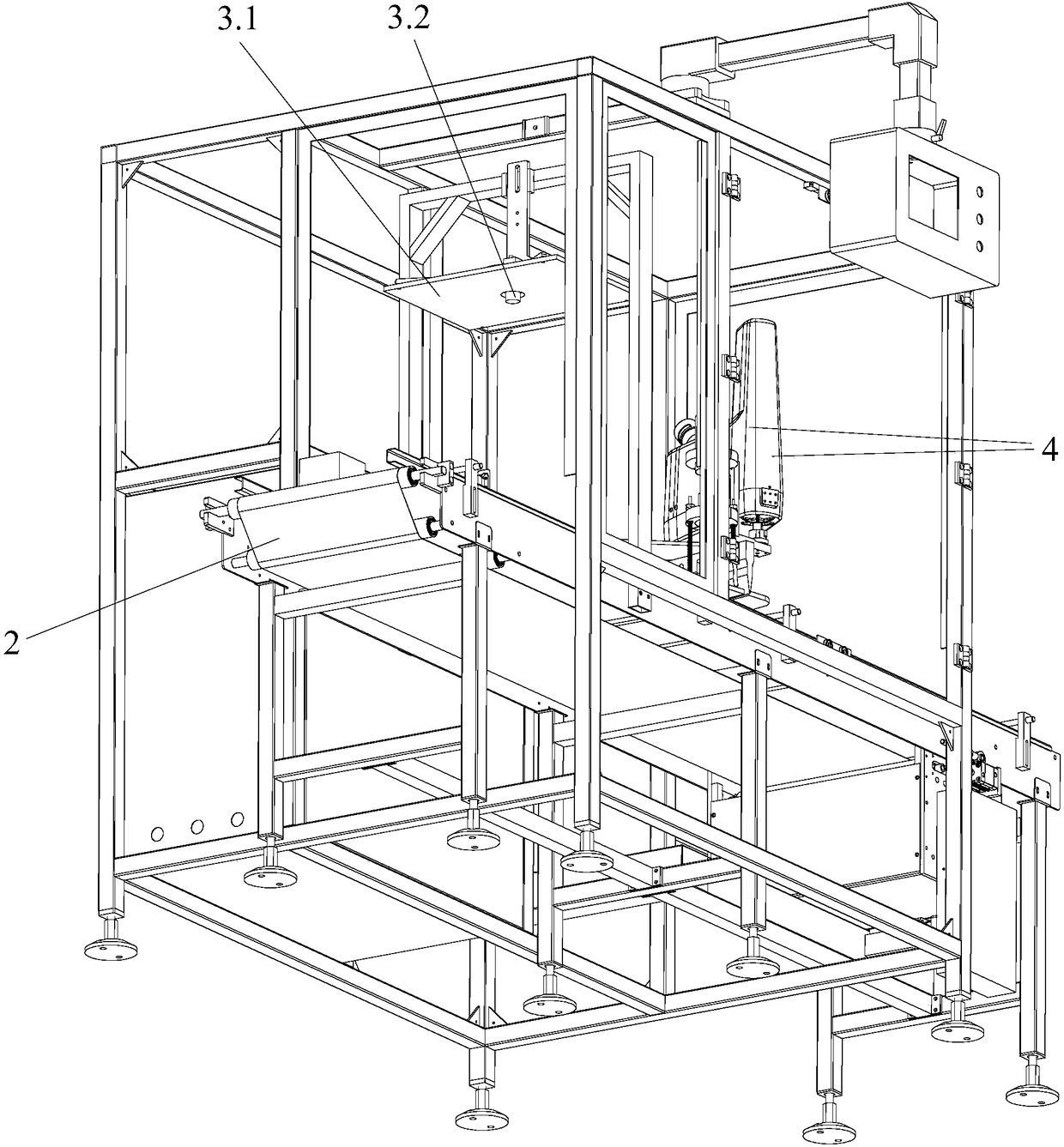

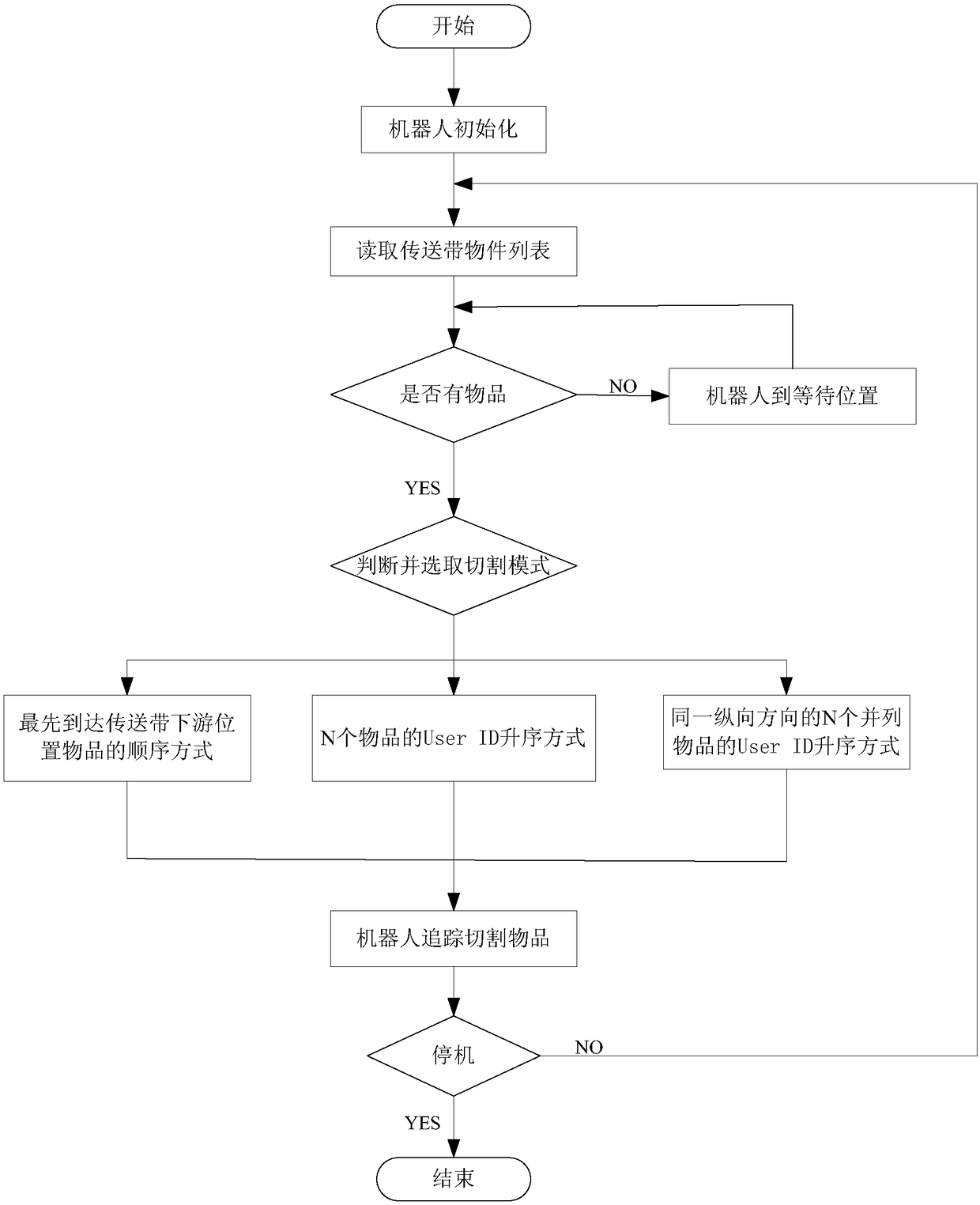

[0063] like figure 1 and figure 2 As shown, a kind of ultrasonic article cutting equipment based on machine vision of the present invention comprises:

[0064] The conveying mechanism is used to convey the article 1. The conveying mechanism includes a conveying belt 2 and a servo motor for driving the conveying belt 2, wherein the conveying belt 2 is divided into an image acquisition area 2.1 and a cutting area 2.2 in sequence along the conveying direction; during operation, the conveying The mechanism transfers the item 1 to the image acquisition area 2.1 and the cutting area 2.2 in sequence;

[0065] The machine vision mechanism 3 is used for image acquisition of the item 1 transmitted to the image acquisition area 2.1, and serves as a starting position for obtaining tracking and positioning information;

[0066] The article cutting mechanism 4 is us...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap