Laser guidance full-automatic car loading robot system

A robotic system and laser-guided technology, used in manipulators, manufacturing tools, etc., can solve the problems of time-consuming and laborious, hidden dangers of mass shipment of products, and large labor consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0080] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

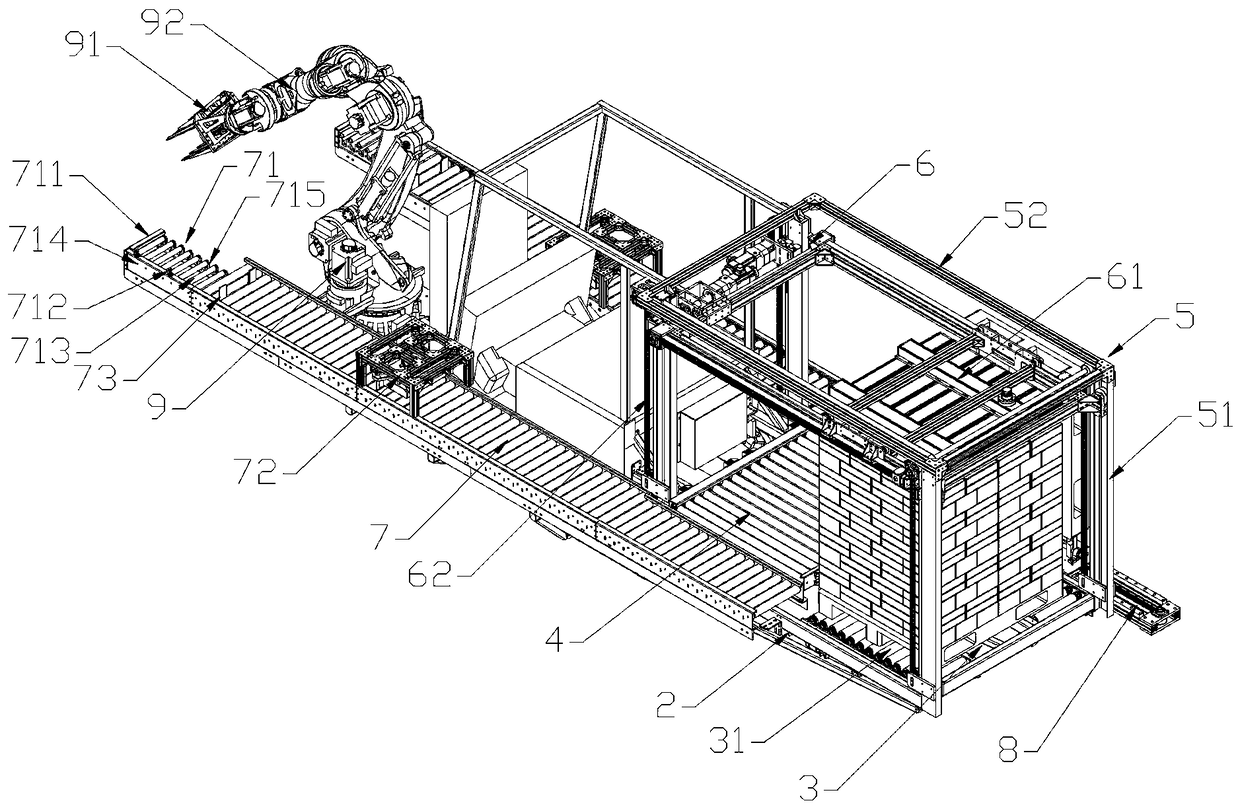

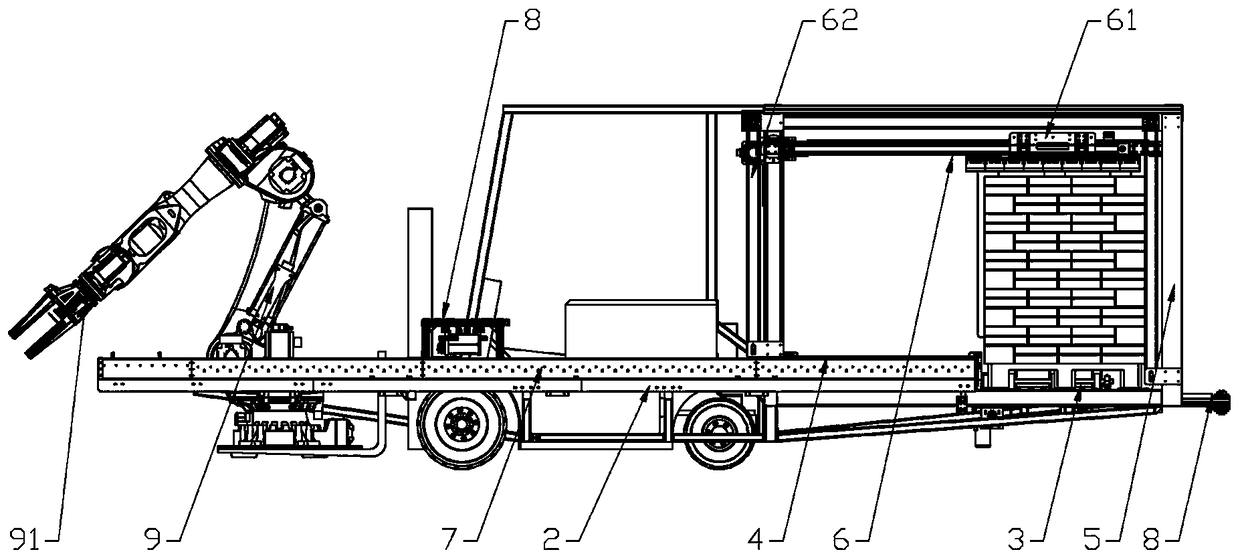

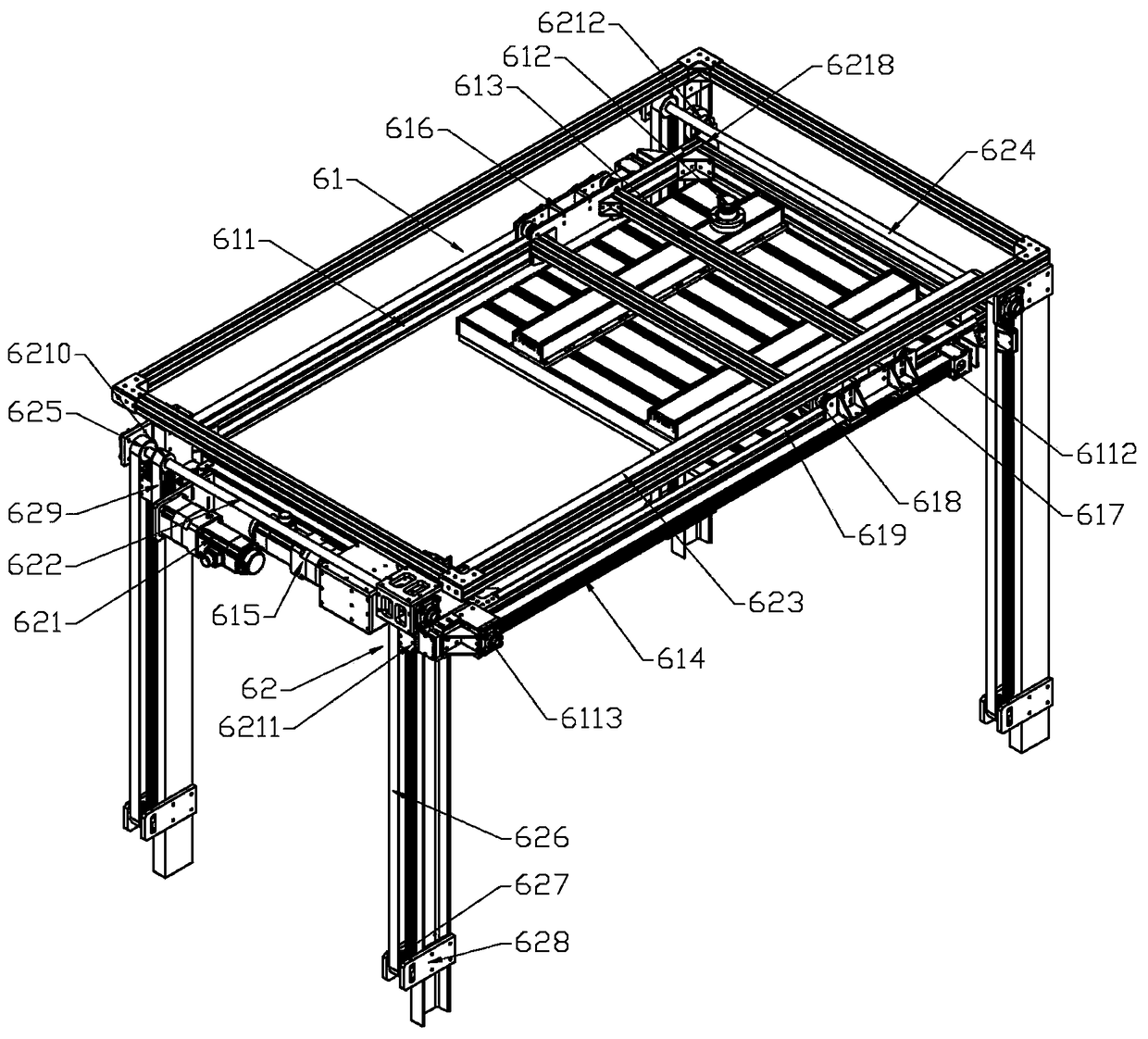

[0081] Such as Figure 1-12 Shown: a laser-guided automatic loading robot system, the automatic loading system includes a mobile chassis 2 capable of driving automatically, the mobile chassis 2 equipped with a servo motor is connected to the motion controller through the servo and IO at the same time, the industrial computer The mobile chassis 2 can be controlled by the motion controller to realize automatic driving, and the wheel hub rotation of the mobile chassis 2 drives the entire loading robot system to drive to the place where the vehicle needs to be loaded; The robot system travels to the location where it needs to be loaded, that is, the mobile chassis 2 can freely switch between manual driving and automatic driving. A frame 5 is arranged at the rear end of the mobile chassis 2, and a stacking tray feeding station 3 located in the frame 5 and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com