Bismuth nanosheets, and preparation method and application thereof

A technology of bismuth nano and bismuth nitrate pentahydrate, which is applied in the field of nanomaterials and can solve the problems of long preparation time, complicated formula and dependence on special equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The invention provides a method for preparing bismuth nanosheets, comprising the following steps:

[0027] Mix bismuth nitrate pentahydrate, ascorbic acid and ethylene glycol to obtain mixed solution A;

[0028] Complexing agent, chloride salt and water are mixed, obtain mixed solution B, and described complexing agent is selected from sodium citrate or sodium tartrate;

[0029] Mix the mixed solution A and the mixed solution B, adjust the pH value, and react under ultrasonic conditions to obtain bismuth nanosheets.

[0030] The method uses common bismuth nitrate pentahydrate as the bismuth source, ascorbic acid with milder reducing properties as the reducing agent, sodium citrate as the complexing agent, potassium chloride as the additive, and ethylene glycol and deionized water as the mixed solvent to adjust the pH. After the value, the bismuth nanosheets were reacted under the assistance of ultrasound. The method can obtain bismuth nanosheets, and the prepared bism...

Embodiment 1

[0046]2mmol of bismuth nitrate pentahydrate and 12mmol of ascorbic acid were stirred and dissolved in 20ml of ethylene glycol to obtain solution A, 6mmol of sodium citrate and 6mmol of potassium chloride were stirred and dissolved in deionized water to obtain solution B, and solution A and solution B were stirred and mixed to obtain For solution C, use 25% to 28% ammonia water to adjust the pH to 12.5, put solution C into an ultrasonic reactor with a temperature of 40°C and a power of 100W, and react for 90 minutes to obtain a precipitate. Centrifuge the precipitate and wash it with deionized water and Washing with absolute ethanol, putting the washed product in a vacuum oven at 40° C. for 10 h to obtain bismuth nanosheet powder.

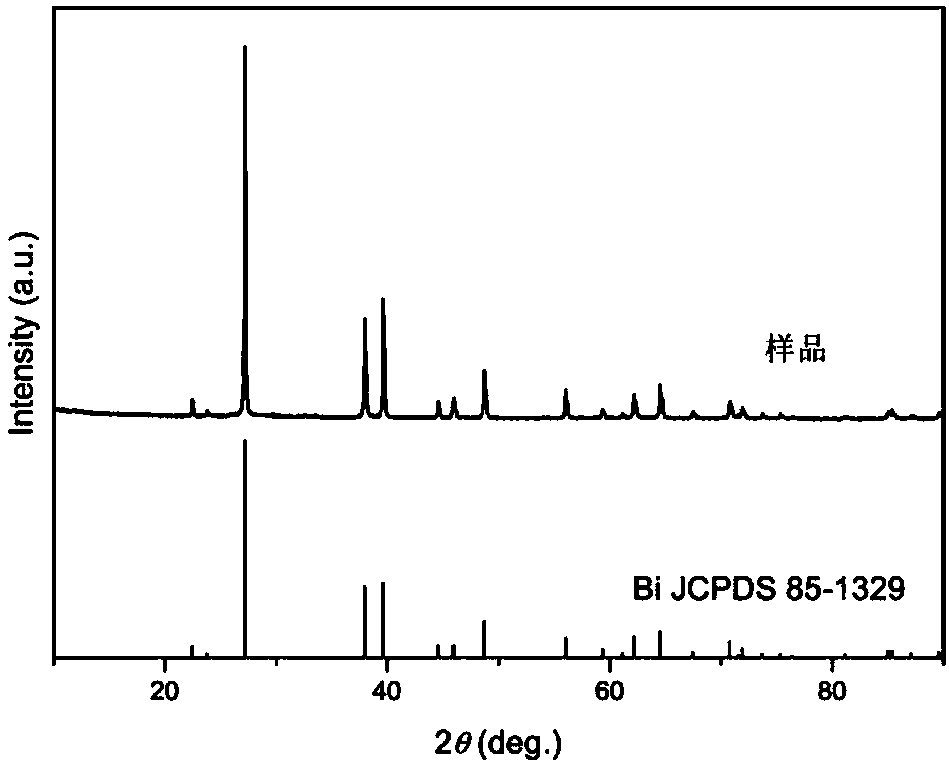

[0047] figure 1 For the XRD analysis figure of the bismuth nanosheets prepared in this example, it can be seen that the bismuth nanosheets prepared in Example 1 of the present invention are consistent with the standard card JCPDS 85-1329, and no imp...

Embodiment 2

[0051] Stir and dissolve 2mmol bismuth nitrate pentahydrate and 6mmol ascorbic acid in 20ml of ethylene glycol to obtain solution A, stir and dissolve 2mmol sodium tartrate and 2mmol potassium chloride in deionized water to obtain solution B, stir and mix solution A and solution B to obtain solution C, adjust the pH value to 13.5 with ammonia water with a mass fraction of 25-28%, put the solution C into an ultrasonic reactor with a temperature of 60°C and a power of 150W, and react for 60 minutes to obtain a precipitate, centrifuge the precipitate and wash it with deionized water and After washing with absolute ethanol, the washed product was dried in a vacuum oven at 60° C. for 7 hours to obtain bismuth nanosheet powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Average width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com