Device for preparing aluminum alloy cast ingot by using induction coil and permanent magnetism mixing in combination with DC

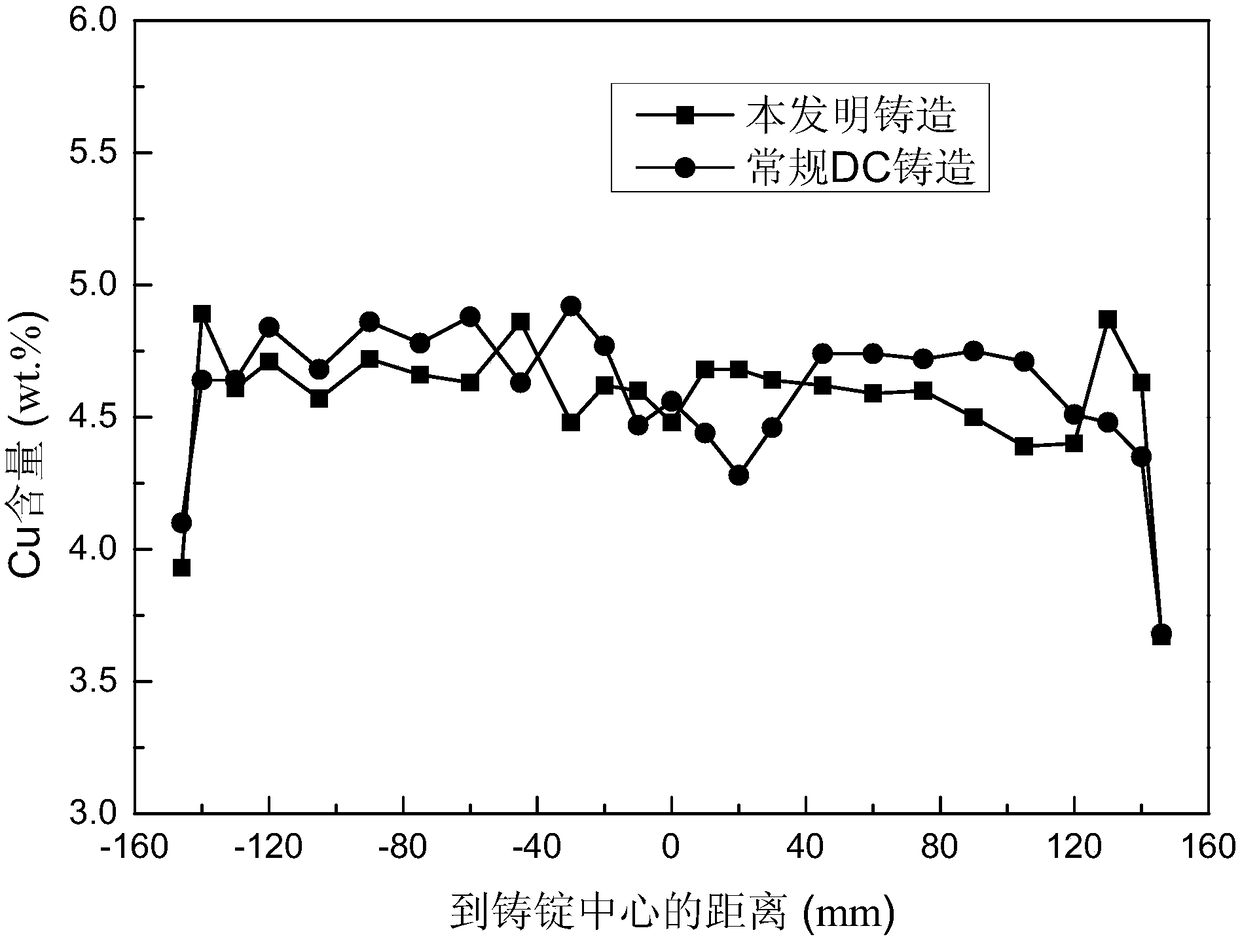

An aluminum alloy ingot and induction coil technology is applied in the field of the device field of the induction coil and the permanent magnet stirring to synergize the DC preparation of the aluminum alloy ingot, which can solve the problems of serious segregation, easy cracking, coarse and uneven structure of the ingot, and the like. Effects of uniform composition, uniform temperature field and composition field, avoiding adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

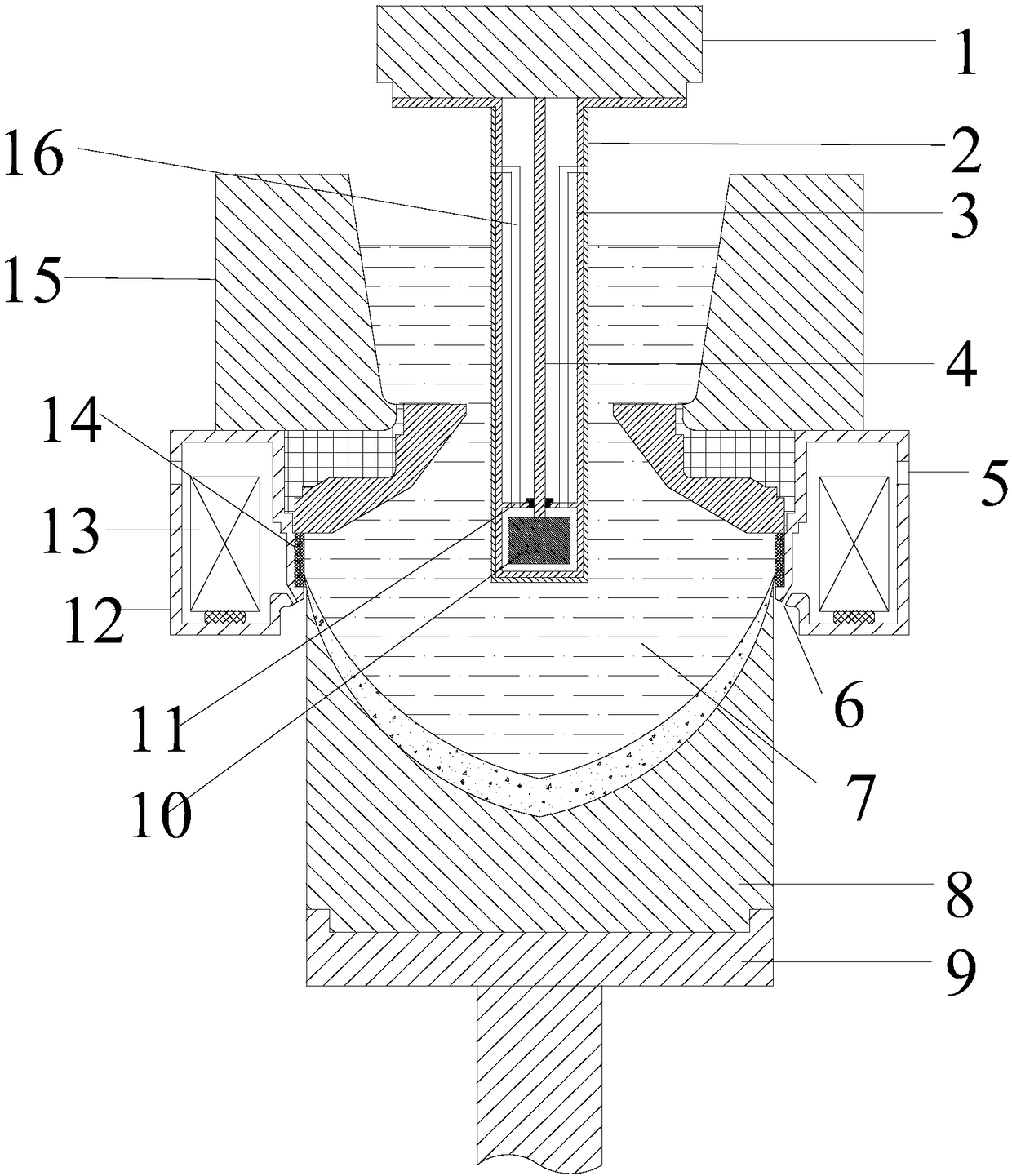

[0039] The device structure of induction coil and permanent magnetic stirring in cooperation with DC to prepare aluminum alloy ingots is as follows figure 1 As shown, it includes a crystallizer, a hot top 15, an induction coil 13, a permanent magnet stirring unit and a dummy bar 9; the induction coil 13 is located in the crystallizer cooling water jacket 12; the inner wall of the crystallizer jacket is inlaid with a graphite ring 14;

[0040]The upper part of the permanent magnet stirring unit is the drive motor 1, and the bottom of the drive motor 1 is the magnetic sleeve 3. The top plate of the magnetic sleeve 3 is fixedly connected with the shell of the drive motor 1, and the magnetic sleeve 3 is covered with a heat-insulating The sleeve 2, the driving motor 1 and the connecting shaft 4 are assembled together, and the bottom end of the connecting shaft 4 is fixedly connected to the permanent magnet 10; the connecting shaft 4 and the permanent magnet 10 are located in the mag...

Embodiment 2

[0053] Device structure is the same as embodiment 1;

[0054] Method is with embodiment 1, and difference is:

[0055] (1) The prepared product is a round ingot of 7050 aluminum alloy, Φ300mm;

[0056] (2) The temperature of the aluminum alloy melt when pouring into the crystallizer is 730-740°C;

[0057] (3) Casting speed 120mm / min;

[0058] The surface of the obtained 7050 aluminum alloy ingot is smooth, without obvious cold shut, no cracks inside the ingot, and the structure is fine and uniform.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com