Pipe end hydraulic forming device for automobile exhaust pipe

A technology for automobile exhaust and hydroforming, applied in the direction of feeding device, positioning device, storage device, etc., can solve the problems of reducing production efficiency, time-consuming and laborious, operator safety threat, etc., and achieve the effect of improving production efficiency and ensuring safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

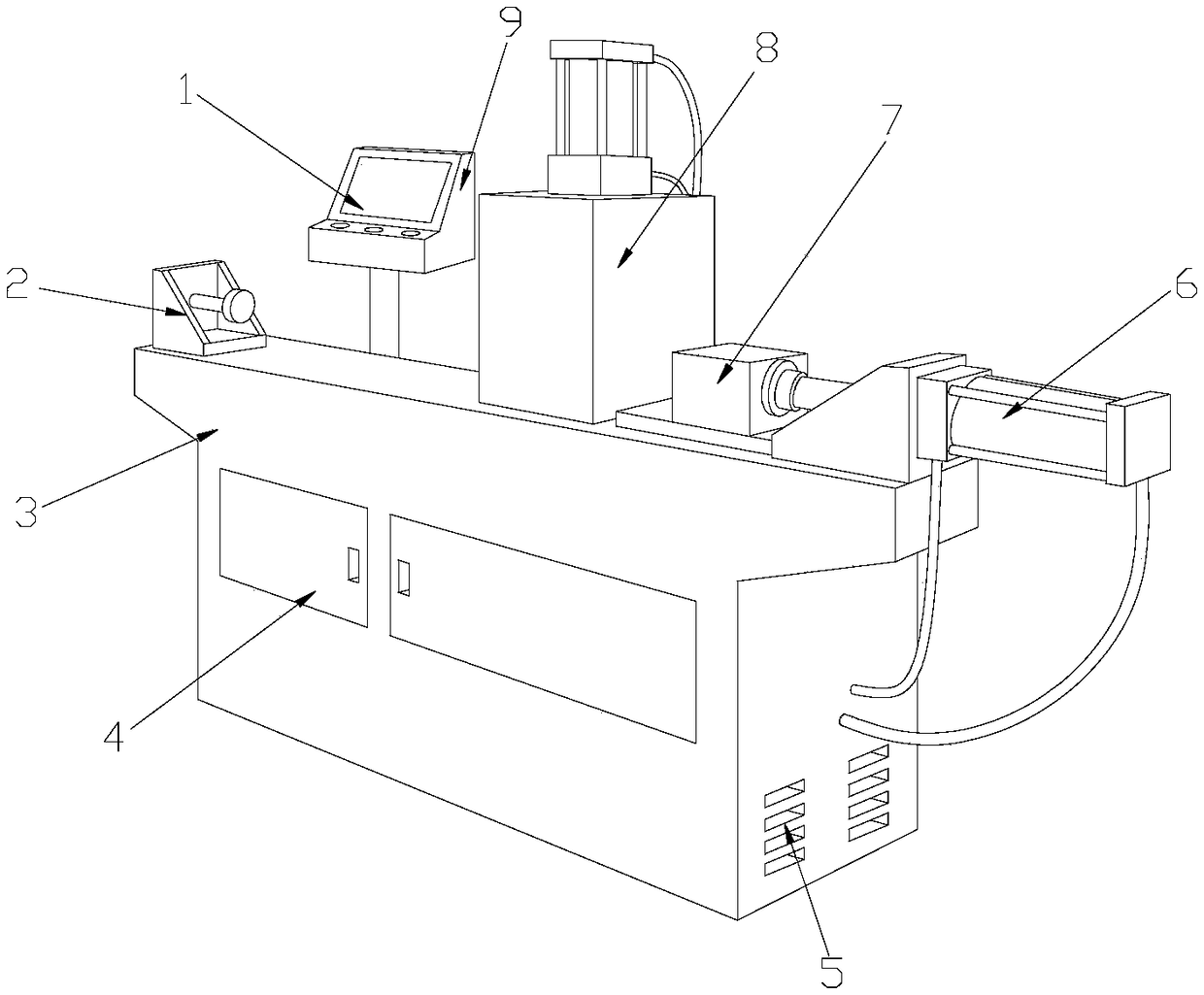

[0021] like Figure 1-Figure 5 As shown in the figure, the present invention provides a hydroforming device for the pipe end of an automobile exhaust pipe. Hydraulic cylinder 6, pipe end forming die 7, clamping and unloading device 8, electrical controller 9, the pipe tail positioning adjustment device 2 is bolted to the leftmost end of the upper surface of the forming machine fixing seat 3, and the equipment inspection door 4 passes through The hinges are connected to the left and right ends of the front of the forming machine holder 3 , the exhaust and heat dissipation holes 5 are evenly distributed on the right side surface of the forming machine holder 3 , and the electrical controller 9 is installed behind the forming machine holder 3 . The liquid crystal display panel 1 is nested in the middle of the front of the electrical controller 9, the clamping and unloading device 8 is mechanically connected to the middle of the upper surface of the fixing base 3 of the molding ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com