Rotary kiln melting method fly ash full resource recovery and tail gas ultra-clean emission method

A technology of rotary kiln and melting method, which is applied in separation methods, chemical instruments and methods, gas treatment, etc., can solve the problems of stricter chloride ion content requirements, restrictions on the promotion of fly ash technology, and low fly ash content, and achieve the realization of The effects of harmless disposal, high social and economic benefits, and uniform distribution of temperature field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

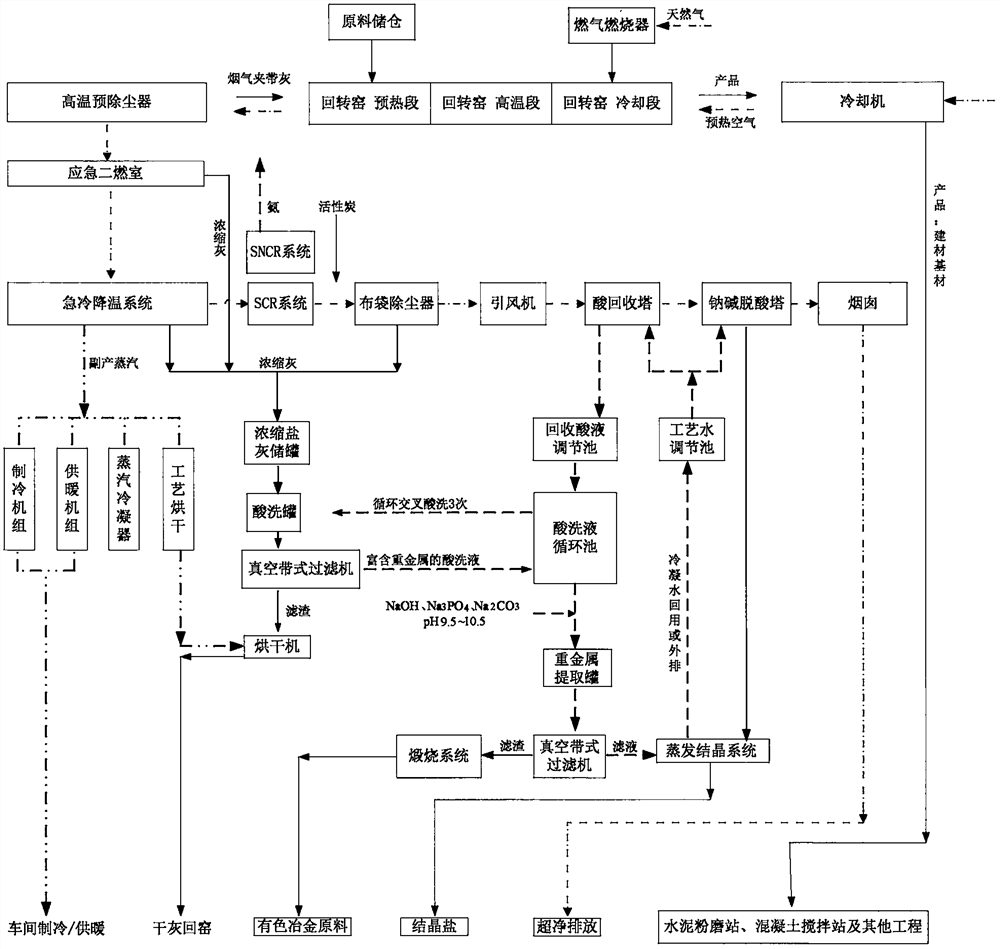

[0035] Below with reference to the accompanying drawings, the present invention will be further described by specific implementation examples, a kind of rotary kiln melting method fly ash full resource recovery and utilization and tail gas ultra-clean discharge method, it comprises following technological process:

[0036] (1) Fly ash melting method disposal system;

[0037] (2) Pre-dust and cooling system;

[0038] (3) Flue gas purification system;

[0039] (4) Concentrated ash pickling system;

[0040] (5) Full resource recovery system for pickling solution;

[0041] The fly ash melting method disposal system includes the following steps:

[0042] The ratio of fly ash and additives in the raw material storage silo is fly ash: additives = 4:1 according to the dry basis of the raw materials. After weighing by the metering screw, they are transported to the screw conveyor, and then transported to the unloading chute after mixing. , enter the rotary kiln from the end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com