Multistage screening system applied to crusher

A crusher and screening technology, which is applied in the direction of filter screen, solid separation, grille, etc., can solve the problems of large space occupation, high noise, low efficiency, etc., and achieve smooth operation, avoid powder accumulation and blockage, and are not easy to wear Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with specific embodiments.

[0022] This embodiment provides a multi-stage screening system applied to crushers. The multi-stage screening system uses a screw conveying device to minimize the vibration transmission between it and the box, thereby weakening the frame vibration of the screening box. It reduces the generation of noise and effectively reduces the noise of equipment operation; at the same time, a multi-stage screen is used, and the screen is combined with a double screen and a single screen, which can effectively absorb fine dust, small light combustibles and large particles; at the same time, the device is easy to assemble, Does not increase the assembly strength of technicians.

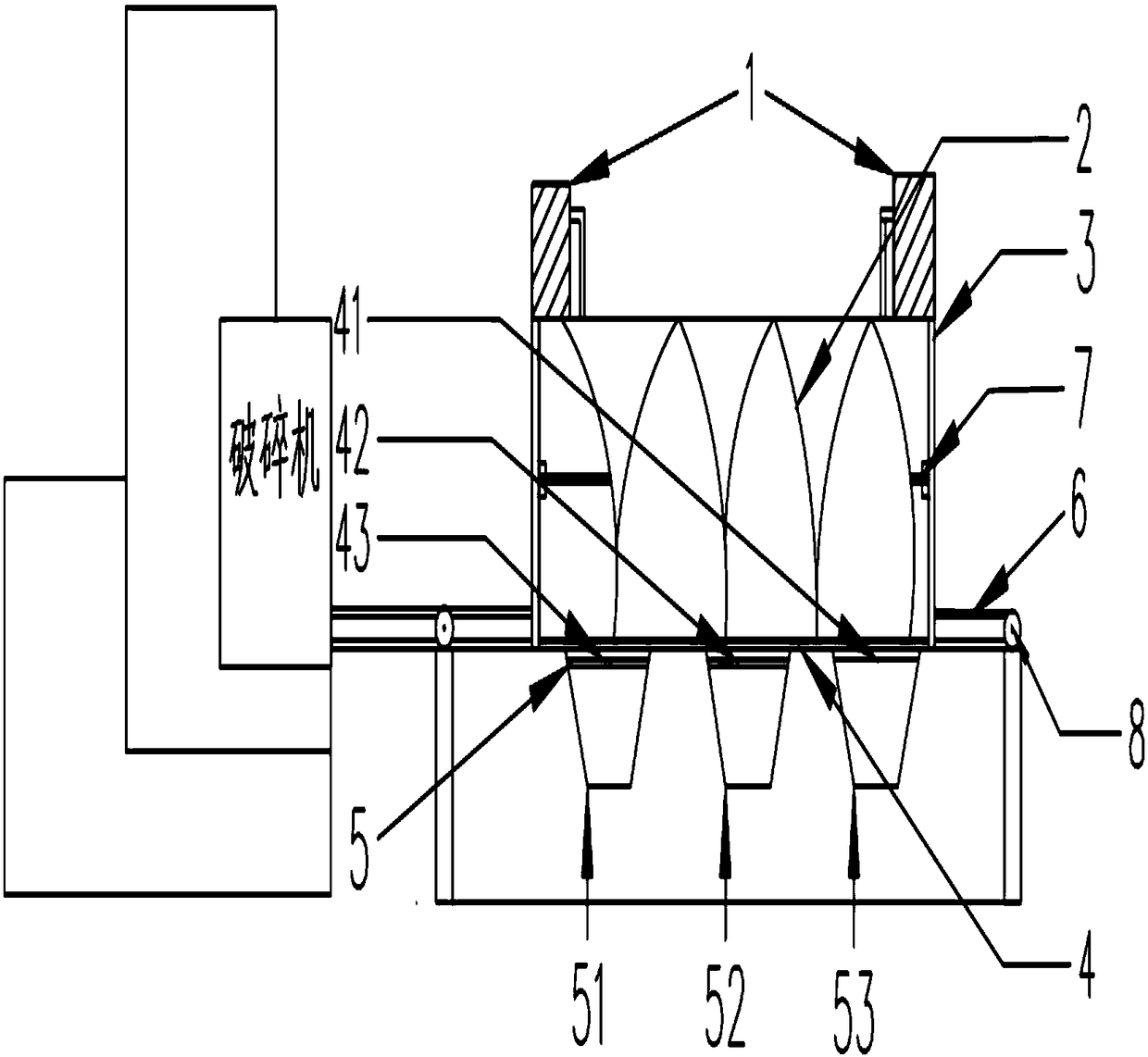

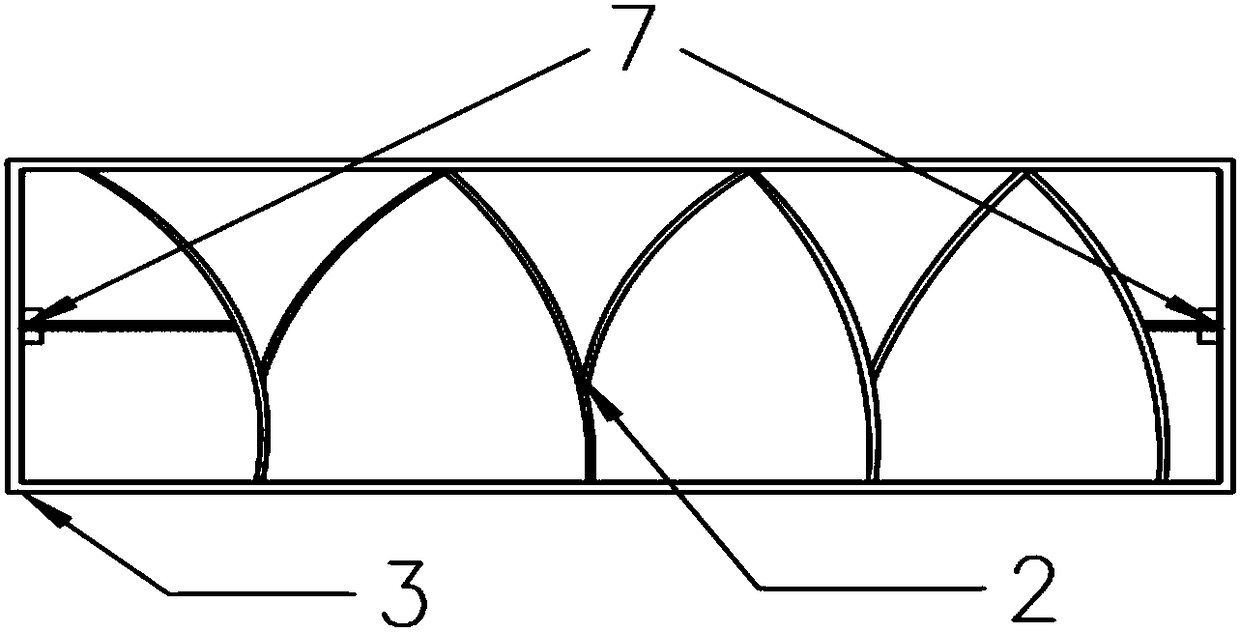

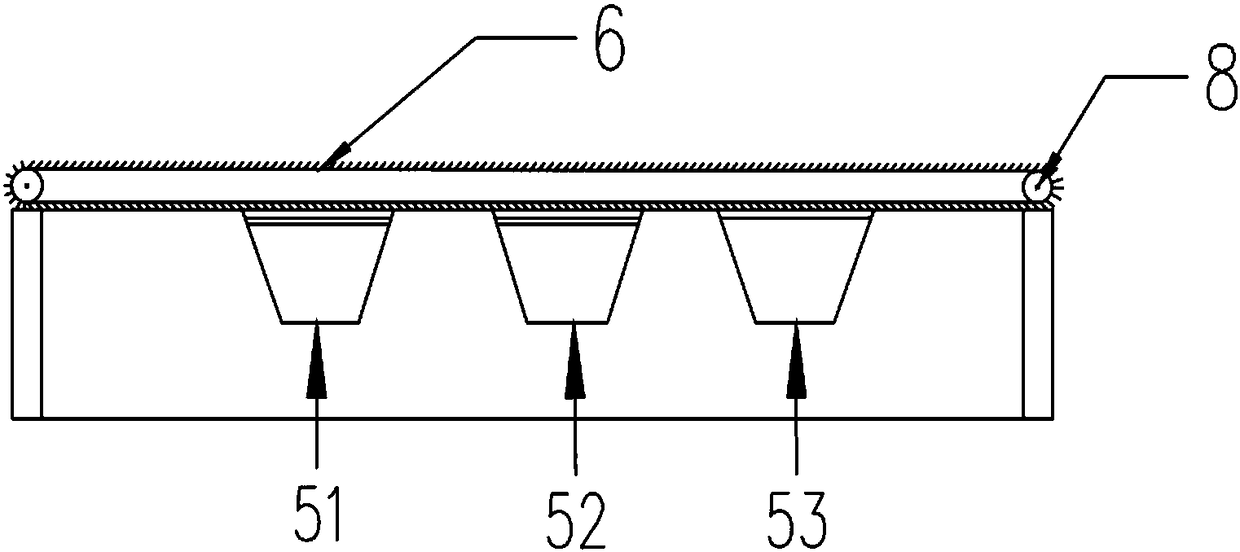

[0023] Such as Figure 1 to Figure 5 As shown, the multi-stage screening system applie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com