Crushing and dust collection device for construction

A technology of dust removal device and construction, applied in grain processing and other directions, can solve the problems of flying fine particles, unstable rotation of grinding rollers, pollution, etc., to reduce harm, maintain stable rotation, and avoid environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Such as figure 1 As shown, a building crushing dust removal device includes a first drive motor 1, a first crushing chamber 2, a second crushing chamber 7 and a filter screen 5 between the first crushing chamber 2 and the second crushing chamber 7, the first There is a feed port 10 above the crushing chamber 2, and a discharge port 11 is located at the bottom of the second crushing chamber 7. The first crushing chamber 2 is located above the second crushing chamber 7 and the two crushing chambers are connected.

[0033] Two transverse crushing rollers are arranged in the first crushing chamber 2, one is the active crushing roller 21, the other is the driven crushing roller 22, and several hammerheads 23 are arranged on the crushing rollers; Both ends extend out of the first crushing chamber 2, the left end of the active crushing roller 21 is connected with the first drive motor 1, the right end is connected with the first gear plate 30, and the right end of the driven c...

Embodiment 2

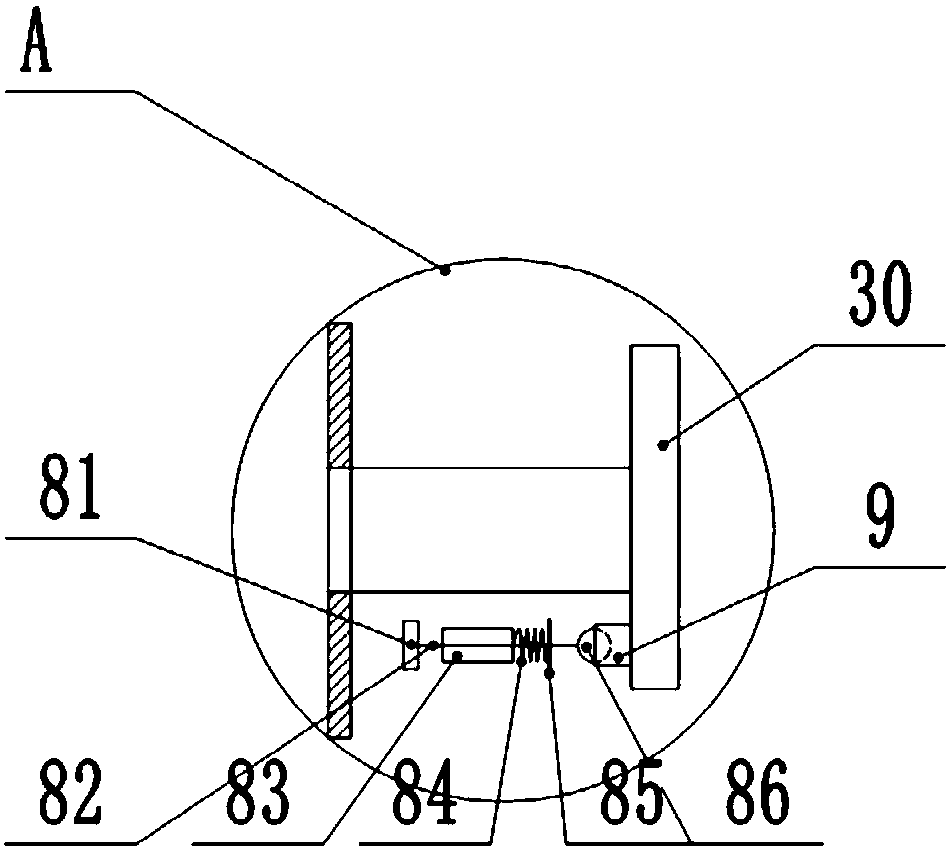

[0040] Such as image 3 As shown, the present embodiment is provided with a vibration mechanism on the basis of Embodiment 1, and its vibration mechanism is composed of a vibration plate 81, a connecting rod 82, a sleeve 83, a spring 84, a baffle plate 85 and a ball 86, and the sleeve 83 is installed On the bracket, the sleeve 83 is slidingly connected with the connecting rod 82, the left end of the connecting rod 82 is connected with the vibrating plate 81, and the right end is connected with the ball 86; the baffle plate 85 is arranged on the connecting rod 82 between the sleeve 83 and the ball 86, and the spring 84 is connected between the sleeve 83 and the baffle 85 . A wedge-shaped protrusion 9 is provided on the gear plate, and the wedge surface of the wedge-shaped protrusion 9 is distributed along the tangential direction of the gear plate, allowing the ball 86 to roll along its wedge surface, wherein the vibration mechanism is located between the first crushing chamber...

Embodiment 3

[0043] Such as figure 1 and Figure 4 As shown, the difference between this embodiment and Embodiment 1 and Embodiment 2 is that the pair of rollers in the second crushing chamber 7 is divided into a driving roller 70 and a driven roller 71, and the rollers are formed along the vertical plane where the centerline of the pair of rollers is located. There are multiple groups, and the positions of the multiple pairs of rollers are staggered, and the synchronous belt 61 is connected on the driving roller 70 . An electrostatic adsorption plate 73 is installed on the inner wall of the second crushing chamber 7, plates 74 are arranged on the end faces of the driving roller 70 and the driven roller 71, and the two scrapers 74 are symmetrical, and the two scrapers 74 sweep along with the rotation of the counter rollers. Electrostatic adsorption plate 73 surface.

[0044] Owing to gas blowing in the first crushing chamber 2, the gas will inevitably pass through the filter screen 5 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com