Dual-channel Z-configuration photocatalytic decomposition water composite material and preparation method thereof

A composite material and photocatalytic technology, applied in the field of photocatalytic water splitting materials, can solve the problems of weak response in the visible light range, slow charge separation and migration, poor material composite uniformity, etc., to achieve good cycle stability, accelerated transfer, and energy saving. The effect of environmental performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

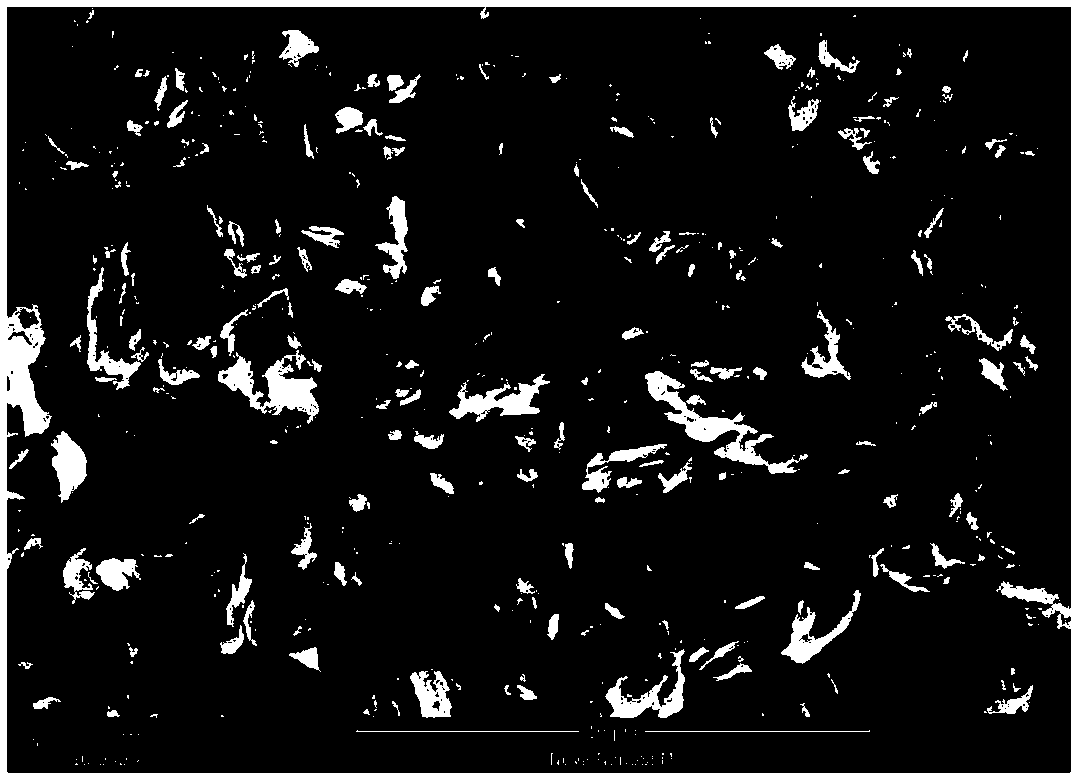

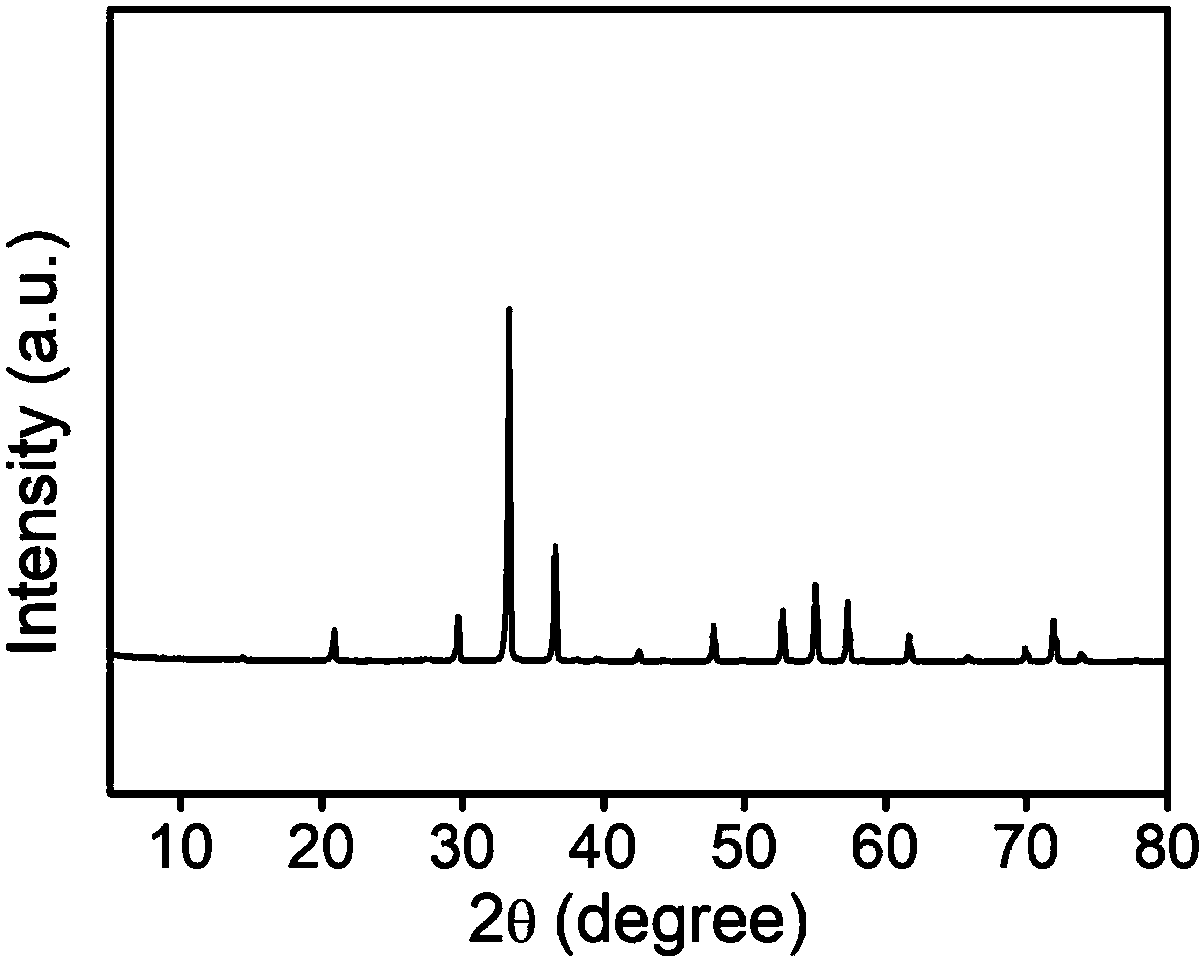

[0034] Weigh 10 mg of prepared carbon nitride, and ultrasonically disperse it uniformly to obtain a carbon nitride dispersion; weigh 9 mmol AgNO 3 Dissolve it in 10 mL of deionized water to obtain 10 mL of AgNO with a concentration of 0.9 mol / L 3 solution; 10 mL of AgNO with a concentration of 0.9 mol / L was stirred 3 The solution was added dropwise into the carbon nitride dispersion, and stirred for 2 hours to obtain a mixed precursor solution. Weigh 10 mg of molybdenum disulfide powder, dissolve it in 50 mL of deionized water and sonicate for 3 hours, so that the molybdenum disulfide layers are fully peeled off to obtain a flaky molybdenum disulfide dispersion. Add the molybdenum disulfide ultrasonic stripping solution dropwise into the above-prepared solution and stir rapidly for 2 hours to obtain a precursor solution; press AgNO 3 with Na 3 PO 4 12H 2 O molar ratio is the ratio of 3:1, takes by weighing 0.3mmol sodium phosphate and is dissolved in 10ml deionized water,...

Embodiment 2

[0036] Weigh 20 mg of prepared carbon nitride, and ultrasonically disperse to obtain a carbon nitride dispersion; weigh 9 mmol AgNO 3 Dissolve it in 10 mL of deionized water to obtain 10 mL of AgNO with a concentration of 0.9 mol / L 3 solution; 10 mL of AgNO with a concentration of 0.9 mol / L was stirred 3 The solution was added dropwise into the carbon nitride dispersion, and stirred for 2 hours to obtain a mixed precursor solution. Weigh 10 mg of molybdenum disulfide powder, dissolve it in 50 mL of deionized water and sonicate for 3 hours, so that the molybdenum disulfide layers are fully peeled off to obtain a flaky molybdenum disulfide dispersion. Add the molybdenum disulfide ultrasonic stripping solution dropwise into the above-prepared solution and stir rapidly for 2 hours to obtain a precursor solution; press AgNO 3 with Na 3 PO 4 12H 2 O molar ratio is the ratio of 3:1, takes by weighing 0.3mmol sodium phosphate and is dissolved in 10ml deionized water, obtains the ...

Embodiment 3

[0038] Weigh 50mg of prepared carbon nitride, and ultrasonically disperse evenly to obtain a carbon nitride dispersion; weigh 9mmol AgNO 3 Dissolve it in 10 mL of deionized water to obtain 10 mL of AgNO with a concentration of 0.9 mol / L 3 solution; 10 mL of AgNO with a concentration of 0.9 mol / L was stirred 3 The solution was added dropwise into the carbon nitride dispersion, and stirred for 2 hours to obtain a mixed precursor solution. Weigh 10 mg of molybdenum disulfide powder, dissolve it in 50 mL of deionized water and sonicate for 3 hours, so that the molybdenum disulfide layers are fully peeled off to obtain a flaky molybdenum disulfide dispersion. Add the molybdenum disulfide ultrasonic stripping solution dropwise into the above-prepared solution and stir rapidly for 2 hours to obtain a precursor solution; press AgNO 3 with Na 3 PO 4 12H 2 O molar ratio is the ratio of 3:1, takes by weighing 0.3mmol sodium phosphate and is dissolved in 10ml deionized water, obtains...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com