Catalyst for high-temperature water gas conversion reaction and manufacturing method thereof

A catalyst, high-temperature water technology, applied in chemical instruments and methods, catalytic treatment of combustible gases, catalysts for physical/chemical processes, etc., can solve the problem of high price of precious metals, and achieve high oxidation reaction efficiency, economy and practicability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

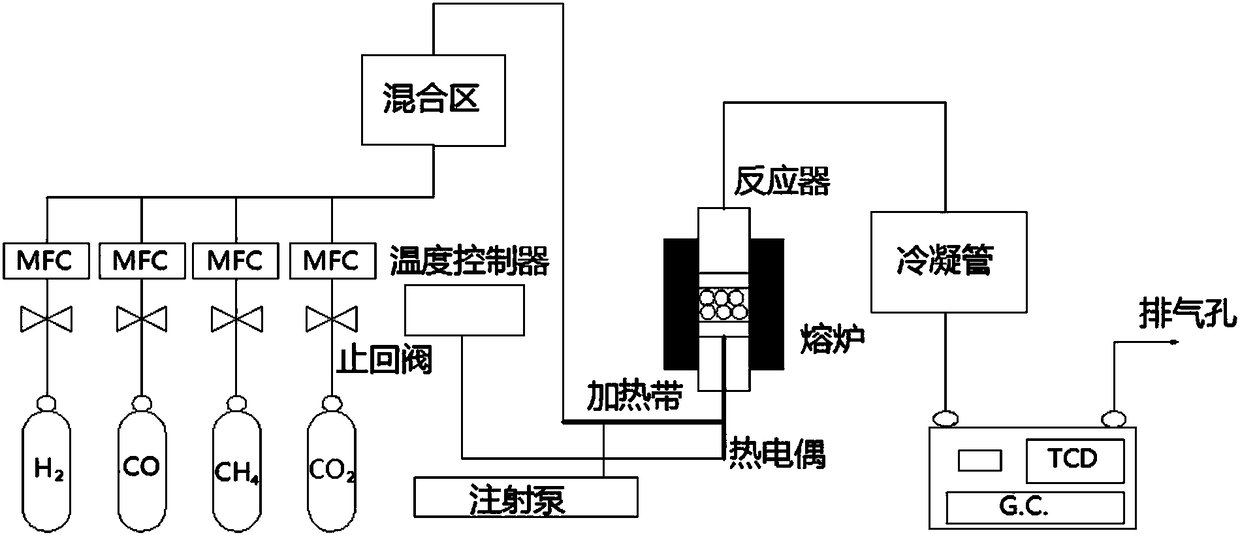

Method used

Image

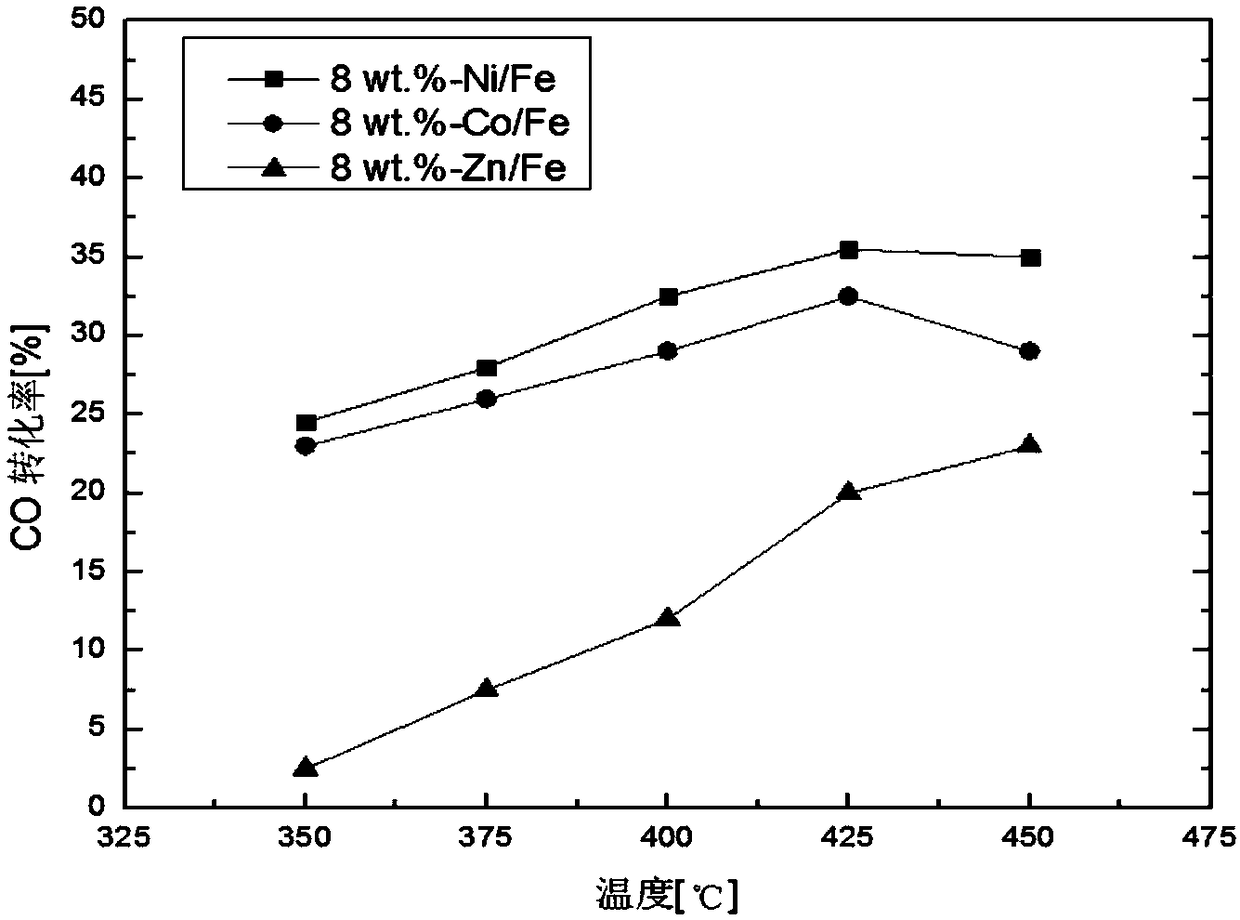

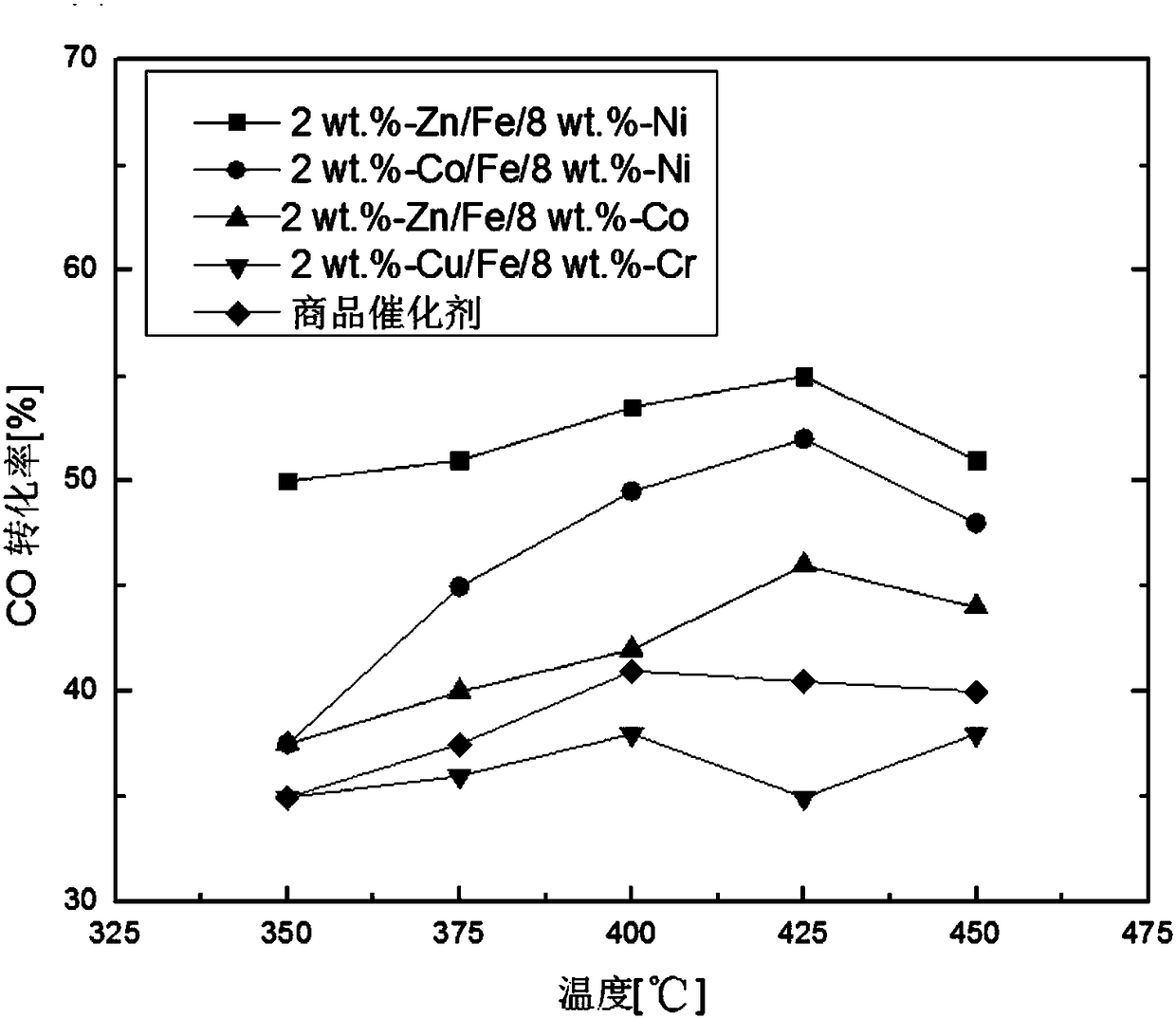

Examples

Embodiment 1

[0027] A catalyst for high-temperature water-gas shift reaction is composed of the following raw materials in weight percentage: 96% iron, 3% nickel, and 1% zinc.

[0028] The preparation method of the catalyst for the high-temperature water-gas shift reaction, the specific steps are as follows:

[0029] (1) Take iron precursor, nickel precursor and zinc precursor respectively as raw materials, calculate the amount of the above-mentioned precursor according to the scope of the weight percentage of the metal content and take the precursor of the required amount for subsequent use;

[0030] (2) Add the iron precursor to 180mL of distilled water, mix and stir with a magnetic stirrer, add the nickel precursor and zinc precursor and then stir;

[0031] (3) Stir the above aqueous solution for 1 h, adjust its pH value to 2.5, add 90 mL of distilled water and 9 g of sodium carbonate mixture, and dry at 65 ° C for 0.8 h;

[0032] (4) Adjust the pH value of the above-mentioned dried pr...

Embodiment 2

[0035] A catalyst for high-temperature water-gas shift reaction, which is composed of the following raw materials according to weight percentage: 88% iron, 10% cobalt, and 2% zinc.

[0036] The preparation method of the catalyst for the high-temperature water-gas shift reaction, the specific steps are as follows:

[0037] (1) Take iron precursor, cobalt precursor and zinc precursor respectively as raw materials, calculate the amount of the above precursor according to the scope of the weight percentage of the metal content and take the required amount of precursor for subsequent use;

[0038] (2) Add the iron precursor to 200mL of distilled water, mix and stir with a magnetic stirrer, add the cobalt precursor and zinc precursor and then stir;

[0039] (3) Stir the above aqueous solution for 1.1 h, adjust its pH to 2.75, add 100 mL of distilled water and 10 g of sodium carbonate mixture, and dry at 70°C for 1 h;

[0040] (4) Adjust the pH value of the above-mentioned dried pro...

Embodiment 3

[0043] A catalyst for high-temperature water-gas shift reaction is composed of the following raw materials according to weight percentage: 82% iron, 15% nickel and 3% cobalt.

[0044] The preparation method of the catalyst for the high-temperature water-gas shift reaction, the specific steps are as follows:

[0045] (1) Take iron precursor, nickel precursor and cobalt precursor respectively as raw materials, calculate the amount of the above-mentioned precursor according to the scope of the weight percentage of the metal content and take the required amount of precursor for subsequent use;

[0046] (2) Add the iron precursor to 220mL of distilled water, mix and stir with a magnetic stirrer, add the nickel precursor and cobalt precursor and then stir;

[0047] (3) Stir the above aqueous solution for 1.2h, adjust its pH value to 3, add 110mL of distilled water and 11g of sodium carbonate mixture, and dry at 75°C for 1.2h;

[0048] (4) Adjust the pH value of the above dried prod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com