Frying machine

A frying pan and interface technology, applied in the field of catering equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

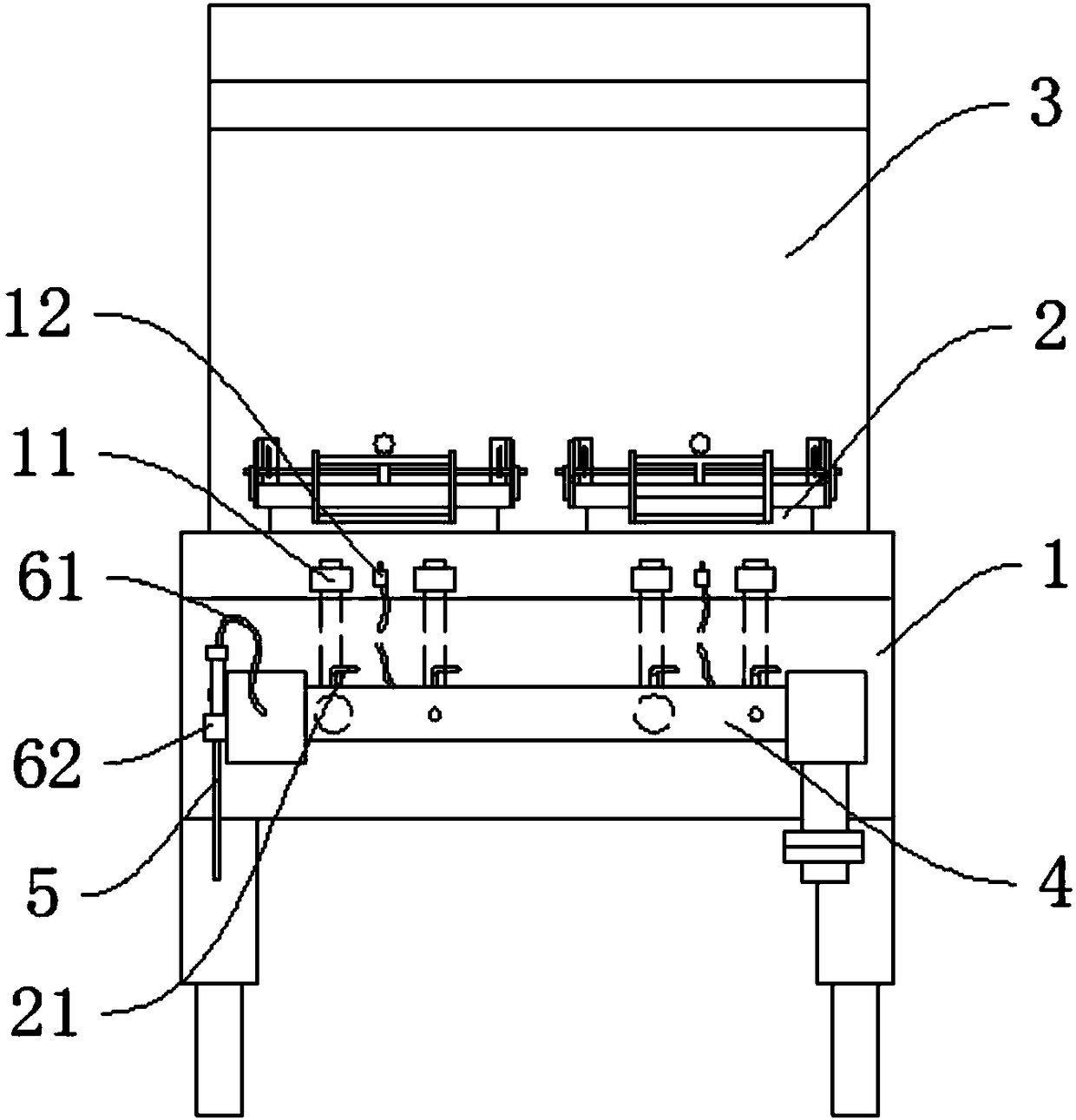

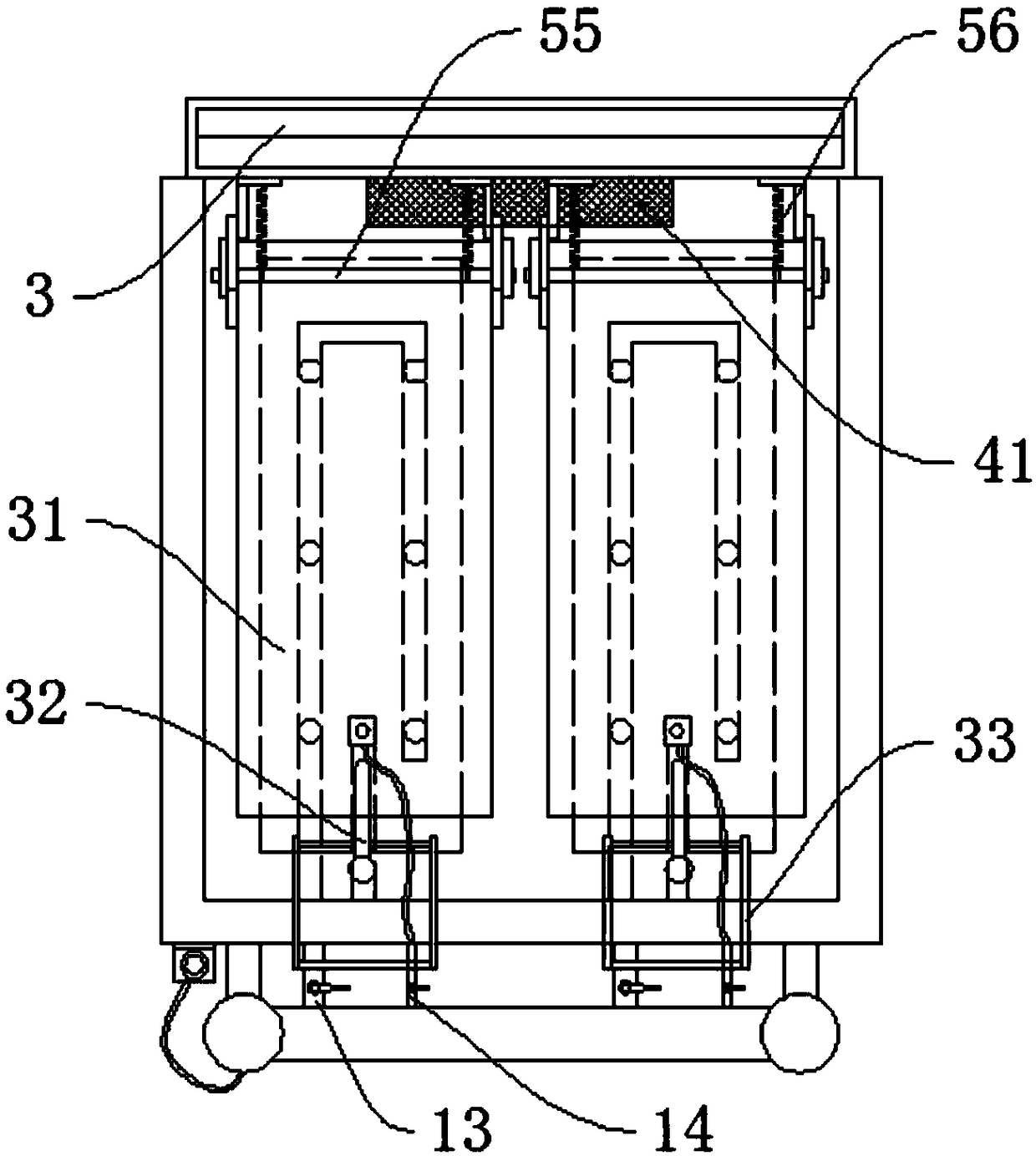

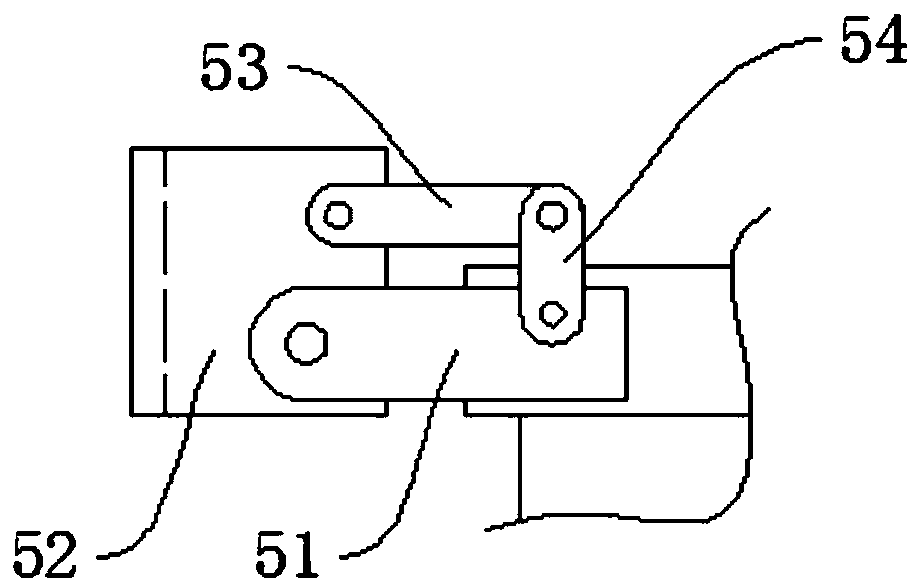

[0017] As shown in the figure, a frying machine includes a stove 1, a frying pan 2, a smoke exhaust pipe 3, a gas interface pipe 4 and an ignition rod 5, and two symmetrically arranged frying pans 2 are arranged above the stove 1 , the frying pan 2 is an elongated tank, and its rear end is hinged in the stove 1 through a shaft. Six fire outlets 11 are arranged below each frying pan 2, and the fire outlets 11 are fixed on the air intake pipe 13, and the air intake pipe 13 and The gas pipeline interface 4 fixed on the outside of the stove 1 is connected, and the gas pipeline interface 4 is also provided with an auxiliary ignition pipeline 14, which is connected to the miniature burner 12, and the miniature burner 12 is adjacent to the outermost fire outlet 11. The air inlet pipe 13 and the auxiliary ignition pipe 14 are respectively provided wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com