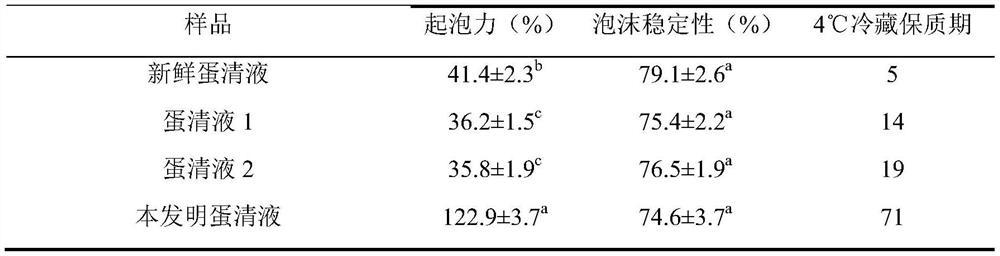

A kind of preparation method of high foaming egg white liquid with long shelf life

A technology of egg white liquid and shelf life, which is applied in heating preservation of eggs, preservation of eggs through radiation/electrical treatment, egg preservation, etc. It can solve the problem of repelling protein deterioration, cumbersome preparation methods, and inability to solve egg white liquid foaming and shelf life at the same time. problems, to achieve high equipment utilization, improve enzymatic hydrolysis efficiency, and improve the effect of chemical reaction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) Carefully select complete and fresh eggs, wash and dry them with water, beat the eggs to remove their shells, separate the eggs to obtain egg whites, use a stirrer to shear and dilute at a speed of 1000r / min for 0.5h, filter to remove the frenulum, and obtain uniformity, Fresh egg white liquid without impurities;

[0034] (2) adding composite protease to the egg white liquid obtained in step (1), the enzyme amount is 1900u / g, and papain occupies 75%;

[0035] (3) Egg white liquid in step (2) is subjected to pulse type ultrasonic treatment, ultrasonic frequency is 20kHz; Ultrasonic power is 400W; Ultrasonic time is 6min;

[0036] (4) Hydrolyze the egg white liquid in step (3), set the hydrolysis temperature to 45°C, and after enzymatic hydrolysis for 45 minutes, increase the ultrasonic power to 800w, and perform ultrasonic treatment for 15 minutes again;

[0037] (5) The egg white liquid obtained in step (4) was raised at 8°C in the hydrolysis equipment and kept for...

experiment example 2

[0039] (1) Carefully select complete and fresh eggs, wash and dry them with water, beat the eggs to remove their shells, separate the eggs to obtain egg whites, use a stirrer to shear and dilute at a speed of 1000r / min for 0.5h, filter to remove the frenulum, and obtain uniformity, Fresh egg white liquid without impurities;

[0040] (2) Add compound protease to the egg white liquid obtained in step (1), the enzyme amount is 1000u / g, and papain occupies 60%;

[0041](3) (3) The egg white liquid in step (2) is subjected to pulse type ultrasonic treatment, the ultrasonic frequency is 20kHz; the ultrasonic power is 600W; the ultrasonic time is 4min;

[0042] (4) After hydrolyzing the egg white liquid in step (3), after enzymatic hydrolysis at a temperature of 45° C. for 30 minutes, increase the ultrasonic power to 1000 W, and perform ultrasonic treatment for 10 minutes again;

[0043] (5) The egg white liquid obtained in step (4) was raised at 8°C in the hydrolysis equipment and ...

experiment example 3

[0045] (1) Carefully select complete and fresh eggs, wash and dry them with water, beat the eggs to remove their shells, separate the eggs to obtain egg whites, use a stirrer to shear and dilute at a speed of 1000r / min for 0.5h, filter to remove the frenulum, and obtain uniformity, Fresh egg white liquid without impurities;

[0046] (2) adding composite protease to the egg white liquid obtained in step (1), the enzyme amount is 1800u / g, and papain occupies 75%;

[0047] (3) The egg white liquid in step (2) is subjected to pulse type ultrasonic treatment, the ultrasonic frequency is 20kHz; the ultrasonic power is 450W; the ultrasonic time is 7min;

[0048] (4) After hydrolyzing the egg white liquid in step (3), enzymatic hydrolysis at 40° C. for 40 minutes, and returning to room temperature in an ice-water bath. Increase the ultrasonic power to 1000w, and perform ultrasonic treatment for 12 minutes again;

[0049] (5) The egg white liquid obtained in step (4) was raised at 9°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com