Air cavity type film bulk acoustic resonator and manufacturing method thereof

A thin-film bulk acoustic wave and manufacturing method technology, applied in electrical components, impedance networks, etc., can solve the problems of reducing device reliability, affecting the electromechanical coupling coefficient of devices, and poor quality of graphene, ensuring stability and reliability, and being easy to scale. Scale implementation, simple production method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

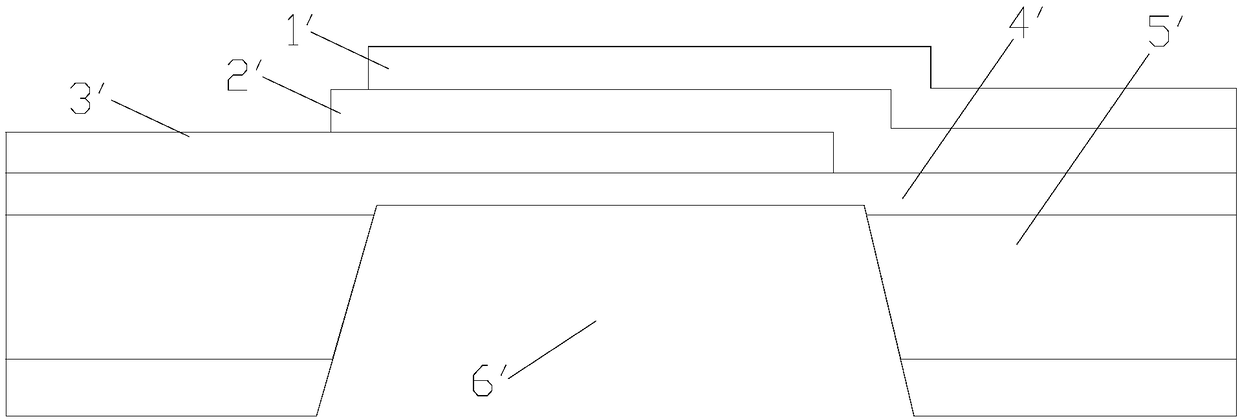

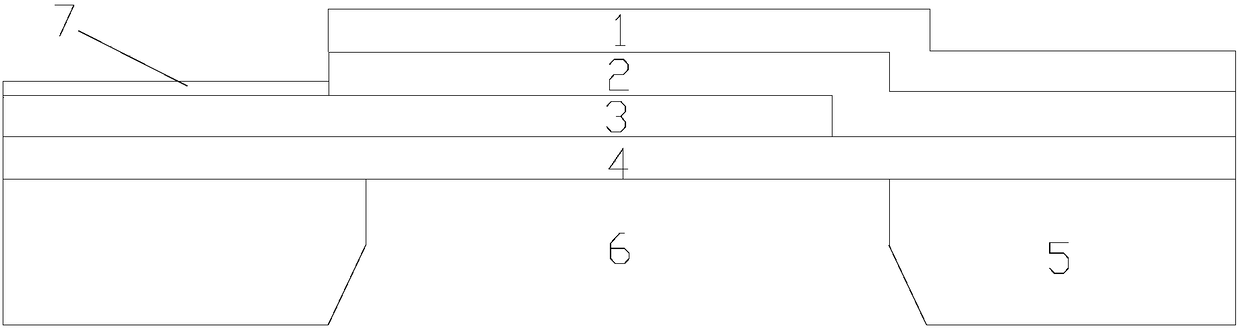

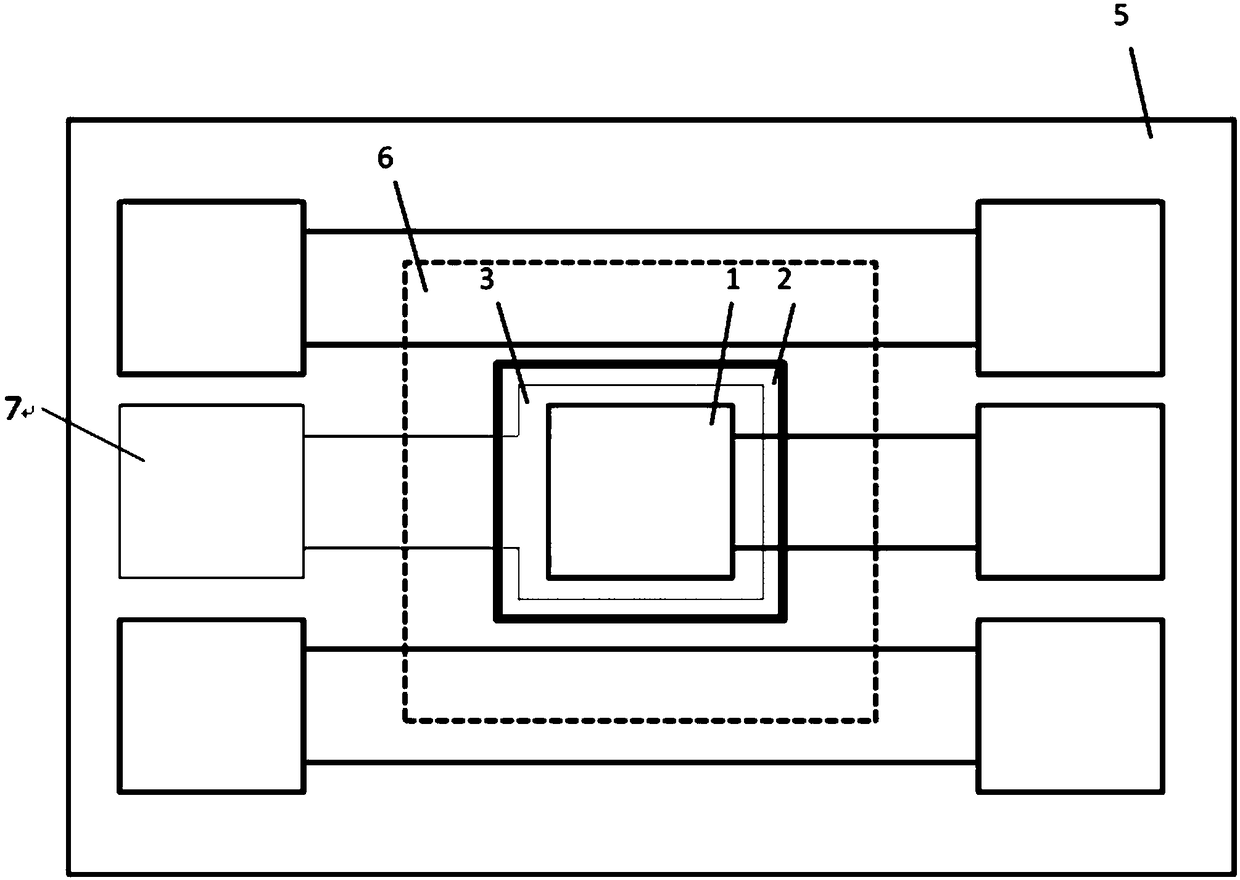

[0022] An aspect of an embodiment of the present invention provides an air cavity thin film bulk acoustic resonator comprising a substrate, a SiC support layer, a graphene lower electrode, a piezoelectric layer and an upper electrode, the substrate has opposite first surface and a second surface, the SiC support layer is arranged on the first surface of the substrate, the graphene lower electrode is arranged on the SiC support layer, and at least a partial area of the piezoelectric layer is covered on the graphene lower electrode Above, the upper electrode is disposed on the piezoelectric layer, and an air cavity is formed on the second surface of the substrate.

[0023] Further, a local area of the piezoelectric layer is directly covered on the SiC supporting layer.

[0024] Further, the material of the piezoelectric layer includes AlN (aluminum nitride), GaN (gallium nitride), or h-BN (hexagonal boron nitride) and the like. Preferably, the piezoelectric layer is made of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com