Preparation method of nitrogen-sulfur co-doped three-dimensional graphene, prepared product and product application thereof

A nitrogen-sulfur co-doping, graphene technology, applied in nanotechnology for materials and surface science, electrical components, electrochemical generators, etc., can solve the problems of harsh experimental conditions, difficult to achieve large-scale preparation, and high cost , to achieve the effect of simple operation, low cost and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) Preparation of precursor by hydrothermal reaction: First, 100 mg of graphene oxide was dispersed in 10 ml of deionized water to obtain a graphene oxide dispersion, then 0.03 g of melamine was added, stirred at 80°C until completely dissolved, and A liquid was obtained; another 0.04 1 g of thiocyanuric acid was dissolved in 25ml of ethanol to obtain liquid B; slowly add liquid B to liquid A, stir at 70°C for 10 minutes and then put it into a hydrothermal kettle with a filling ratio of 35% and a hydrothermal reaction temperature of 120°C / 4h. After the hydrothermal reaction is completed, freeze-dry to obtain the precursor.

[0023] (2) Preparation of three-dimensional doped graphene by heat treatment: the precursor was placed in a tube furnace, protected by argon, and heated to 600°C at a heating rate of 2°C / min for 5 hours.

Embodiment 2

[0025] (1) Preparation of precursor by hydrothermal reaction: First, disperse 100 mg of graphene oxide in 25 ml of deionized water to obtain a graphene oxide dispersion, then add 0.13 g of melamine, stir at 80°C until completely dissolved, and obtain liquid A; another 0.18 1 g of thiocyanuric acid was dissolved in 25ml of ethanol to obtain liquid B; slowly add liquid B to liquid A, stir at 80°C for 60 minutes, then put it into a hydrothermal kettle, the filling ratio is 50%, and the hydrothermal reaction is 200°C / 12h. After the hydrothermal reaction is completed, freeze-dry to obtain the precursor.

[0026] (2) Preparation of three-dimensional doped graphene by heat treatment: the precursor was placed in a tube furnace, protected by argon, and heated to 700 °C at a heating rate of 5 °C / min for 2 h.

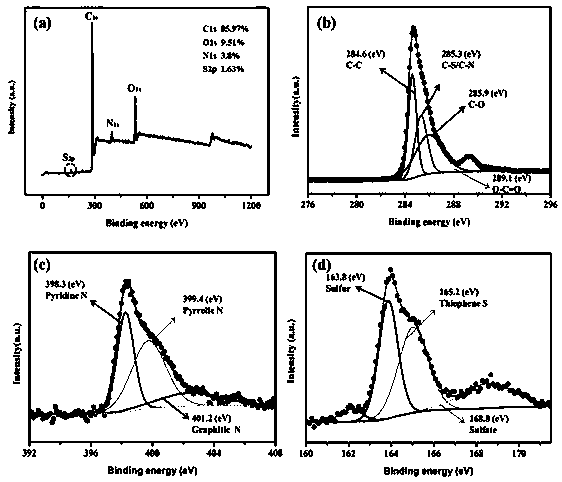

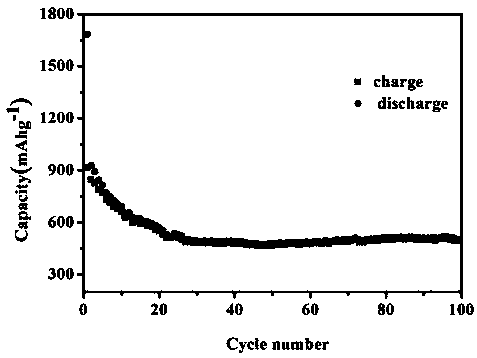

[0027] refer to figure 1 , figure 1 SEM photographs of samples prepared for this example. Using the S-4800 scanning electron microscope (SEM) of Japan Electronics Co., Ltd. t...

Embodiment 3

[0031] (1) Preparation of precursor by hydrothermal reaction: First, disperse 100 mg of graphene oxide in 20 ml of deionized water to obtain a graphene oxide dispersion, then add 0.252 g of melamine, stir at 120 °C until completely dissolved, and obtain liquid A; another 0.354 Dissolve thiocyanic acid in 25ml of ethanol to obtain liquid B; slowly add liquid B to liquid A, stir at 120°C for 10 minutes, then put it into a hydrothermal kettle, the filling ratio is 55%, and the hydrothermal reaction is 150°C / 36h . After the hydrothermal reaction is completed, freeze-dry to obtain the precursor.

[0032] (2) Preparation of three-dimensional doped graphene by heat treatment: the precursor was placed in a tube furnace, protected by argon, and heated to 1000 °C at a heating rate of 10 °C / min for 1 h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com