Production technology device of semiconductor material

A production technology, semiconductor technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as air pollution, unfavorable production and use of small and medium-sized enterprises, expensive cleaning equipment, etc., and achieve the effect of convenient operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

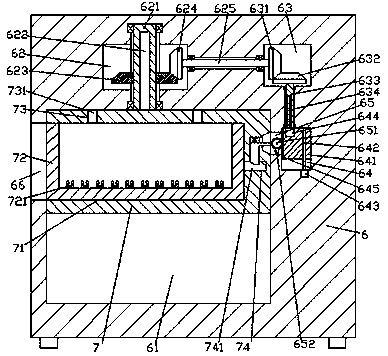

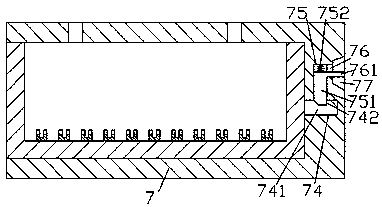

[0012] Combine below Figure 1-3 The present invention will be described in detail.

[0013] refer to Figure 1-3 According to an embodiment of the present invention, a semiconductor material production technology equipment includes a main body 6, a cleaning chamber 61 is provided in the main body 6, and a cleaning chamber 61 is provided in the left end surface of the main body 6. The opening groove 66 provided in communication, a first cavity 62 is provided in the main body 6 on the upper side of the cleaning chamber 61, and a second cavity is provided in the main body 6 on the right side of the first cavity 62. cavity 63, the main body 6 on the right side of the cleaning cavity 61 is provided with a third cavity 64, the third cavity 64 is located at the lower side of the second cavity 63, and the cleaning cavity 61 The lifting frame body 7 is connected by sliding fit, and the internal thread sleeve 621 extending up and down is connected with the rotation fit in the first c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com